Thin-sheet-type self-heating element, preparation method and application thereof

A self-heating, sheet technology, applied in chemical instruments and methods, contraceptives, heat exchange materials, etc., can solve the problems of unstable heating temperature, damage, contamination and damage of human body or clothing, etc., to improve the stability of heating temperature, No material leakage problem, stable heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

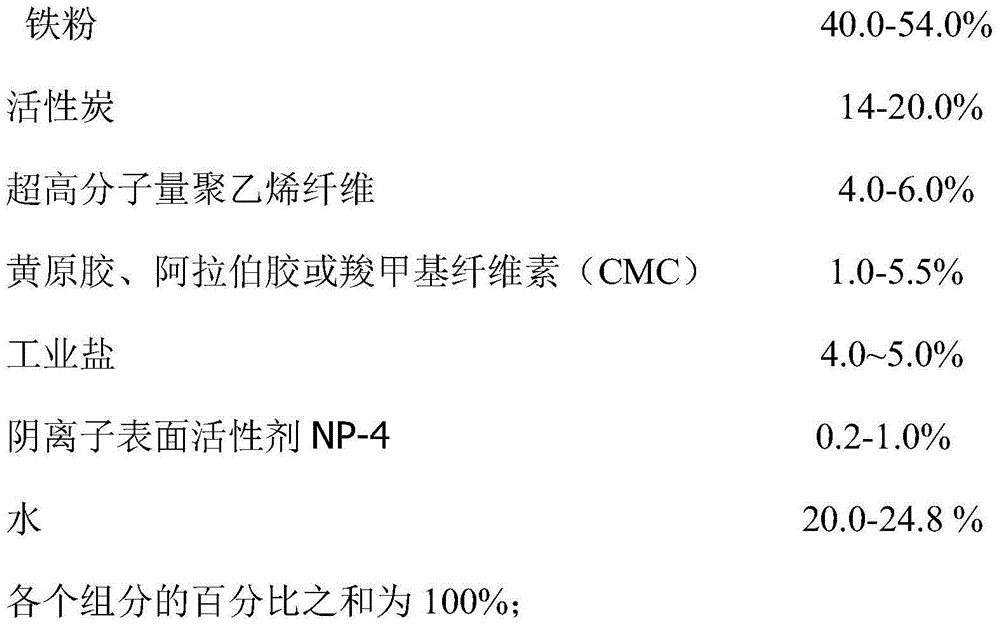

[0021] formula:

[0022]

[0023] The thickness of the sheet-type self-heating body is 1mm; the width is 100mm and the length is 100mm

[0024] The molecular weight of the ultra-high molecular weight polyethylene fiber is 1×10 6 ;

[0025] The preparation method of the present invention: mix xanthan gum, industrial salt, and NP-4 at normal temperature to obtain a paste, and let it stand for 10 hours; the added weight of water is 10 times the weight of xanthan gum;

[0026] At room temperature, add iron powder and activated carbon ultra-high molecular weight polyethylene fiber, stir and mix, press into a sheet, and then dry at 180°C for 1.5 hours under a vacuum of 720 torr to obtain the sheet-type self-heating body. The recipe amount of water is added at the point of use.

[0027] How to use: After adding the prescribed amount of water, put it into a bag made of microporous oxygen-permeable film covered with non-woven fabric, and pack it in an oxygen-insulating plastic ou...

Embodiment 2

[0031] formula:

[0032]

[0033] The thickness of the sheet-type self-heating body is 4mm; the width is 100mm and the length is 100mm

[0034] The molecular weight of the ultra-high molecular weight polyethylene fiber is 3×10 8 ;

[0035] The preparation method of the present invention: mix gum arabic, industrial salt, NP-4 and NP-4 at normal temperature to obtain a paste, and leave it to stand for 10 hours; the added weight of water is 15 times of the weight of gum arabic;

[0036] At room temperature, add iron powder and activated carbon ultra-high molecular weight polyethylene fiber, stir and mix, press into a sheet shape, and then dry at 180°C for 1.5 hours under a vacuum of 720 Torr to obtain the sheet-type self-heating body. The recipe amount of water is added at the point of use.

[0037] Using method is the same as embodiment 1.

[0038] The test method described below is used for detection:

[0039] The duration of fever is 155min.

[0040] Average temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com