High-efficiency energy-saving cement grinding aid and preparation method thereof

A cement grinding aid, high-efficiency and energy-saving technology, applied in the field of cement, can solve the problems that cement enterprises cannot save costs and the performance of grinding aid is single, and achieve the effects of improving cement performance, reducing production costs and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

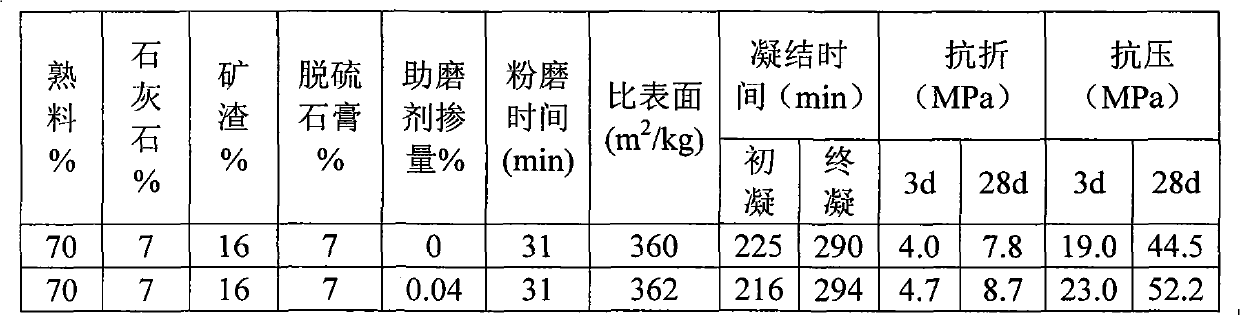

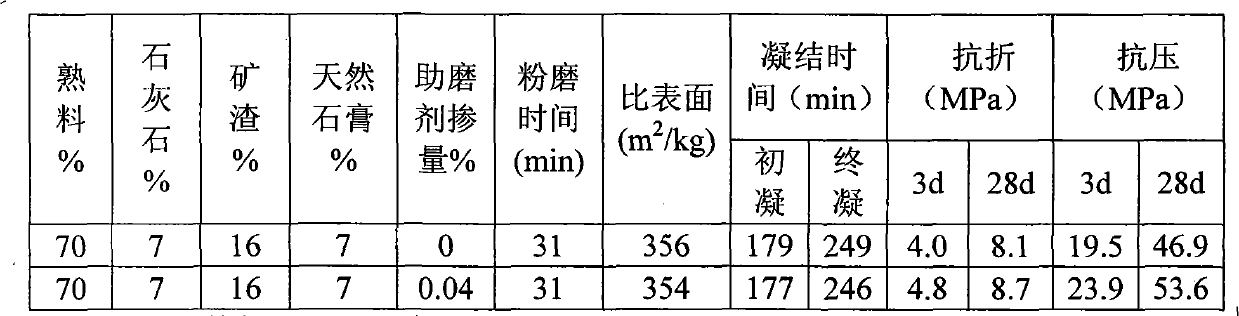

[0011] First, add 0.5 kg of polyacrylamide to 50 kg of water, heat and stir slightly (the temperature does not exceed 60 ° C), and after it is completely dissolved, add 10 kg of calcium chloride into it, stir and dissolve, and then add 3 kg of calcium chloride Calcium formate was added therein and stirred to dissolve. Then add 6.5 kg of sodium gluconate to fully dissolve it, and finally add 10 kg of ethylene glycol and 20 kg of triethanolamine and stir evenly. The added weight percentage of the grinding aid in the cement is 0.04%. Weigh 5 kg of cement raw materials and 2 grams of grinding aid, respectively adopt natural gypsum and desulfurized gypsum as blank samples, grind for 31 minutes through a test ball mill, and then take samples according to GB / T17671-1999 "Cement mortar strength test method (ISO) method "Tested, the results of the cement test are shown in Table 1 and Table 2.

[0012] Table 1 adopts natural gypsum as the cement test effect data of blank sample

[00...

Embodiment 2

[0020] First, add 0.5 kg of polyacrylamide to 50 kg of water, heat and stir slightly (the temperature does not exceed 60°C), and after it is completely dissolved, add 6.5 kg of sodium carbonate into it, stir and dissolve, and then add 3 kg of formic acid Calcium was added therein and stirred to dissolve. Then add 8 kilograms of sodium gluconate to make it fully dissolved. Finally, 12 kg of propylene glycol and 20 kg of triethanolamine are added and stirred evenly.

Embodiment 3

[0022] First, add 0.5 kg of polyacrylamide to 45 kg of water, heat and stir slightly (the temperature does not exceed 60°C), and after it is completely dissolved, add 9.5 kg of calcium chloride into it, stir and dissolve, and then add 3 kg of calcium chloride Calcium formate was added therein and stirred to dissolve. Then add 7 kg of sodium gluconate to fully dissolve it. Finally, 15 kg of ethylene glycol and 20 kg of triethanolamine are added and stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com