Preparation of long-chain alkyl acyl benzene sulfonic acid sodium salt and application thereof in enhancing oil recovery rate

A long-chain sodium alkylacylbenzenesulfonate and sodium alkylacylbenzenesulfonate technology, which is applied in the direction of sulfonate preparation, drilling compositions, chemical instruments and methods, etc., can solve problems such as difficulty in raw material supply, Achieve the effects of enhanced oil recovery, wide source of acid chloride and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Preparation of dodecyllauroylbenzene intermediate

[0029] Industrial grade dodecylbenzene (Jinling Petrochemical Nanjing Alkylbenzene Plant) and lauroyl chloride (analytical grade, China Pharmaceutical Group Shanghai Chemical Reagent Company) were used in AlCl 3 (analytical pure, Shanghai Chemical Reagent Company, China Pharmaceutical Group) reacted in the presence of dodecylbenzene, the amount of dodecylbenzene was 0.1mol, the molar ratio of dodecylbenzene to lauroyl chloride was 1:2, lauroyl chloride and AlCl 3 The molar ratio is 1:1.2, lauroyl chloride is added dropwise under ice bath, the dropping temperature does not exceed 5°C, after the dropwise temperature is raised to 50°C, and the reaction is continued for 4h. After the reaction is completed, 60 mL of 5 mol / L concentrated hydrochloric acid is added to hydrolyze the complex under ice-bath conditions, and the acylation conversion rate of the alkylbenzene can reach more than 98%. Extract with aqueo...

Embodiment 2

[0034] Embodiment 2 Preparation of sodium dodecyllauroylbenzenesulfonate (DLBS)

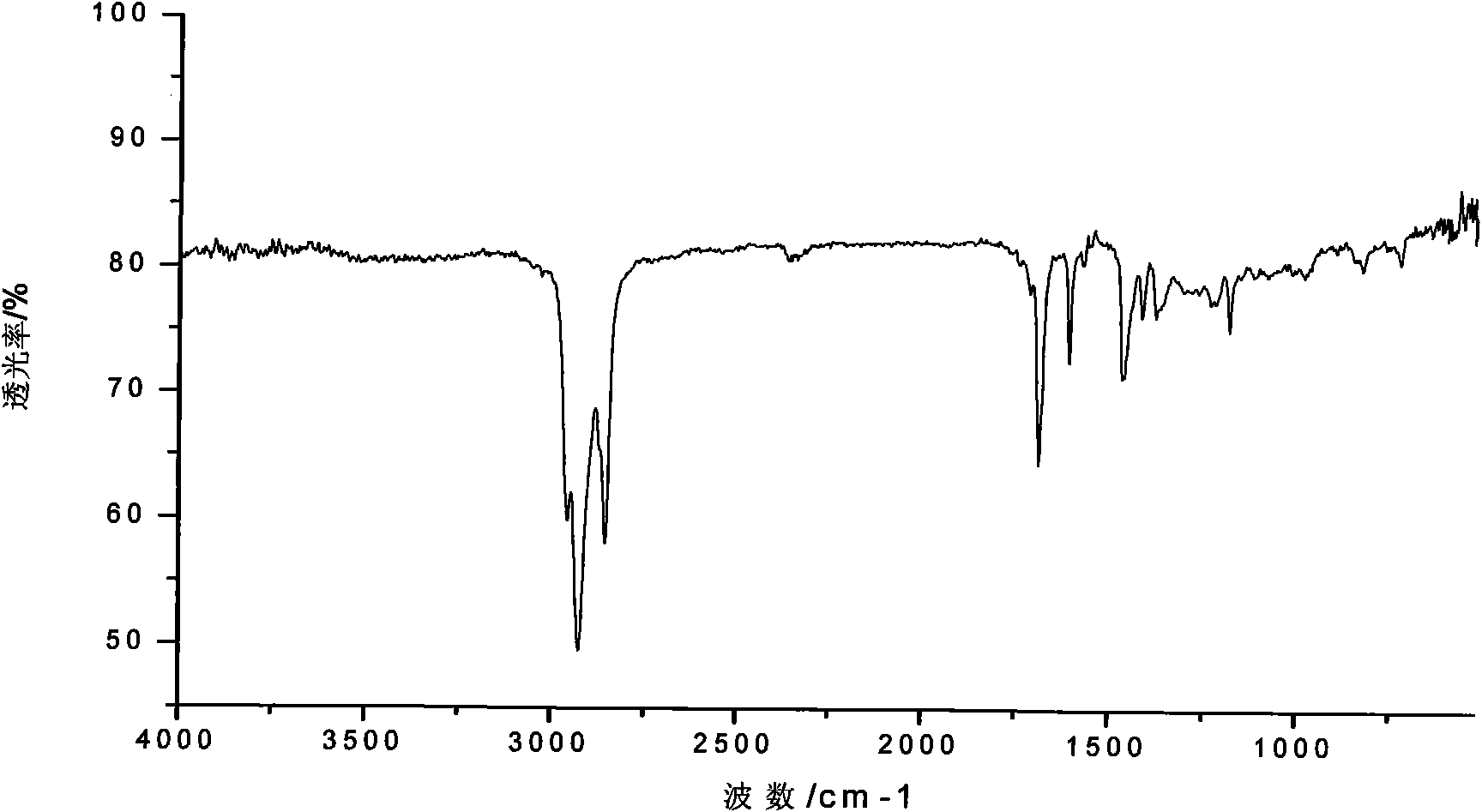

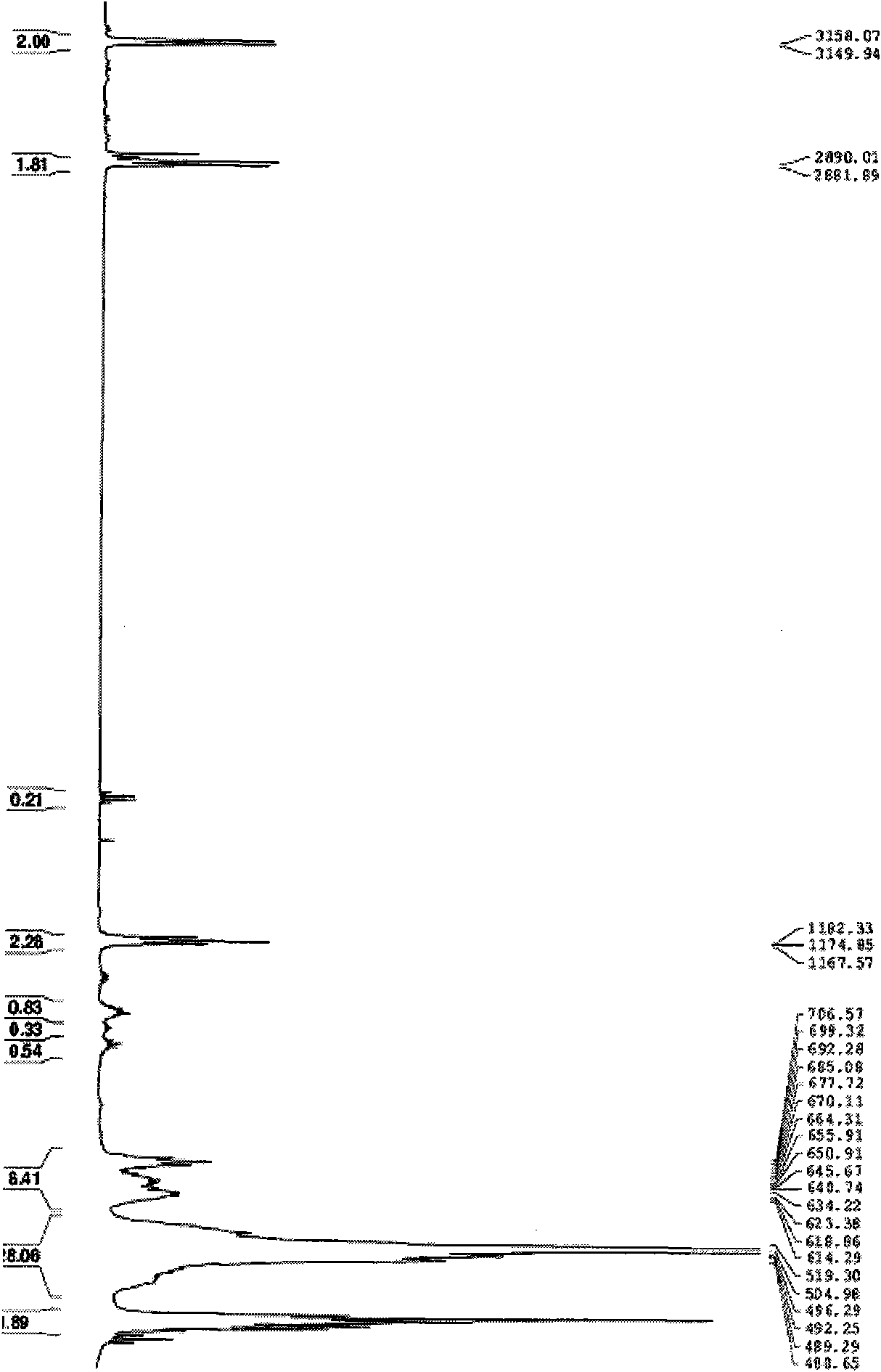

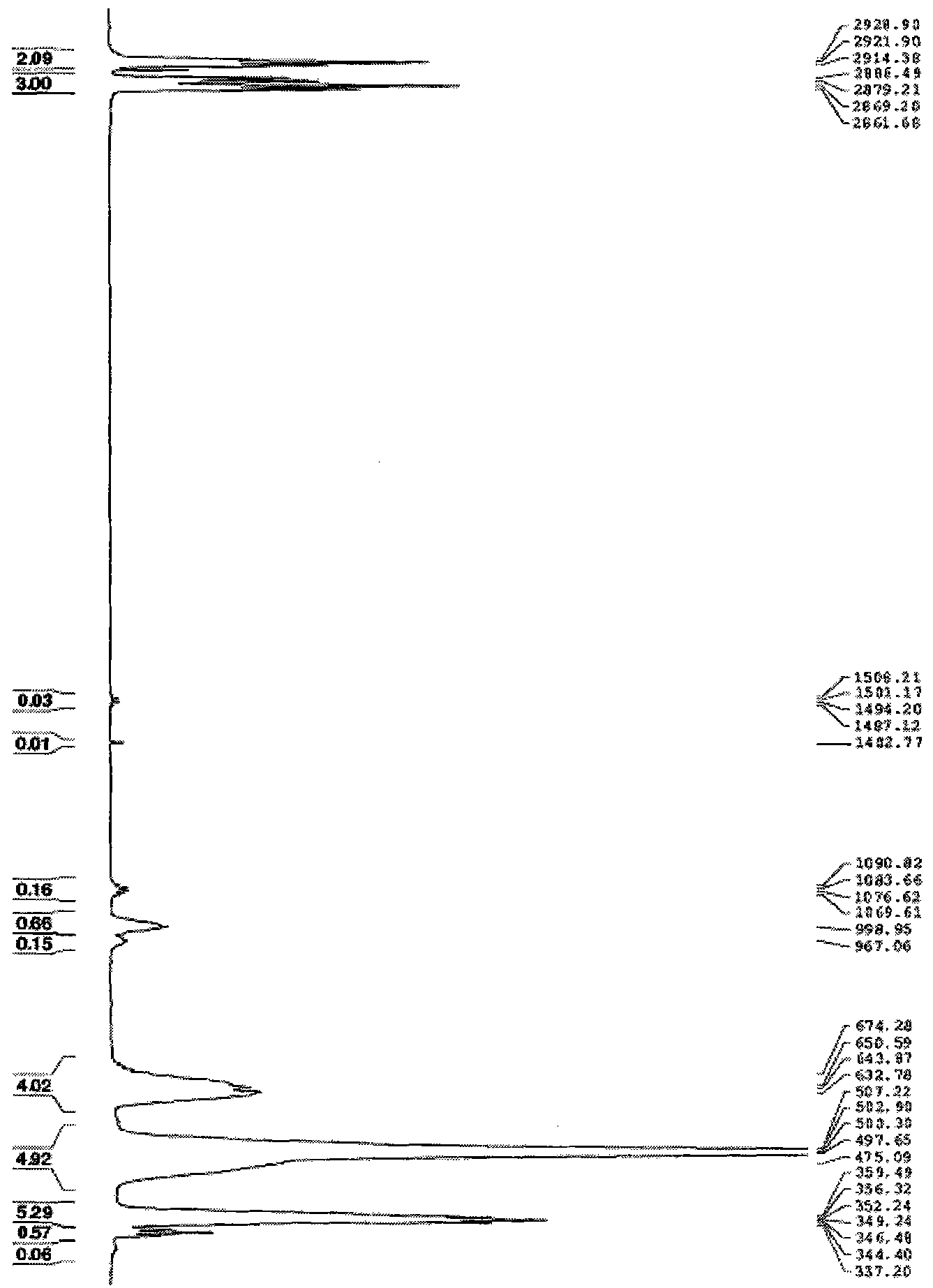

[0035] DLB was sulfonated with chlorosulfonic acid. The amount of DLB is 0.035mol, the molar ratio of DLB to chlorosulfonic acid is 1:2.6, the reaction temperature is 30°C, and the reaction time is 4h. After the reaction is completed, the sulfonated product is neutralized with 30% NaOH aqueous solution to obtain a crude DLBS product with a sulfonation rate close to 70%. After petroleum ether extraction, desalting and column chromatography (strongly basic polystyrene anion exchange resin), the purified DLBS is obtained. Figure 4 IR spectrum of DLBS at 1685cm -1 There is a clear carbonyl absorption peak. Figure 5 It is the mass spectrum of DLBS. In the negative charge mode, the mass / charge ratio of the anion is generally M-Na, from Figure 5 It can be seen that a group of mass / charge ratio = 479.2, 493.3, 507.3, 521.3 molecular ion peaks, exactly the target product C 10 ~C 13 Alkyl lau...

Embodiment 3

[0036] The surface chemistry performance test of embodiment 3 DLBS:

[0037] Dissolve DLBS in pure water, measure the surface tension at 45°C, and compare with LAS, HABS2#, HABS1#, the surface tension changes with the concentration as follows Image 6 As shown, the relevant surface active parameters are shown in Table 3. It can be seen from Table 3 that the cmc of DLBS is 1.1×10 -5 mol / L, γ cmc It is 28.6mN / m, and its surface activity is better than that of HABS and LAS.

[0038] Table 3 The critical micelle concentration cmc of DLBS, the effectiveness of reducing surface tension γ cmc , the saturated adsorption capacity Γ max And the molecular cross-sectional area a at the gas / liquid interface during saturated adsorption ∞ and its comparison with the corresponding parameters of LAS and HABS

[0039] product

[0040] Figure 7 It is the interfacial tension between DLBS aqueous solution (5mM) and normal alkanes with different chain lengths. It can be seen that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com