Wet catalytic oxidation clean pulping process and equipment for implementing same

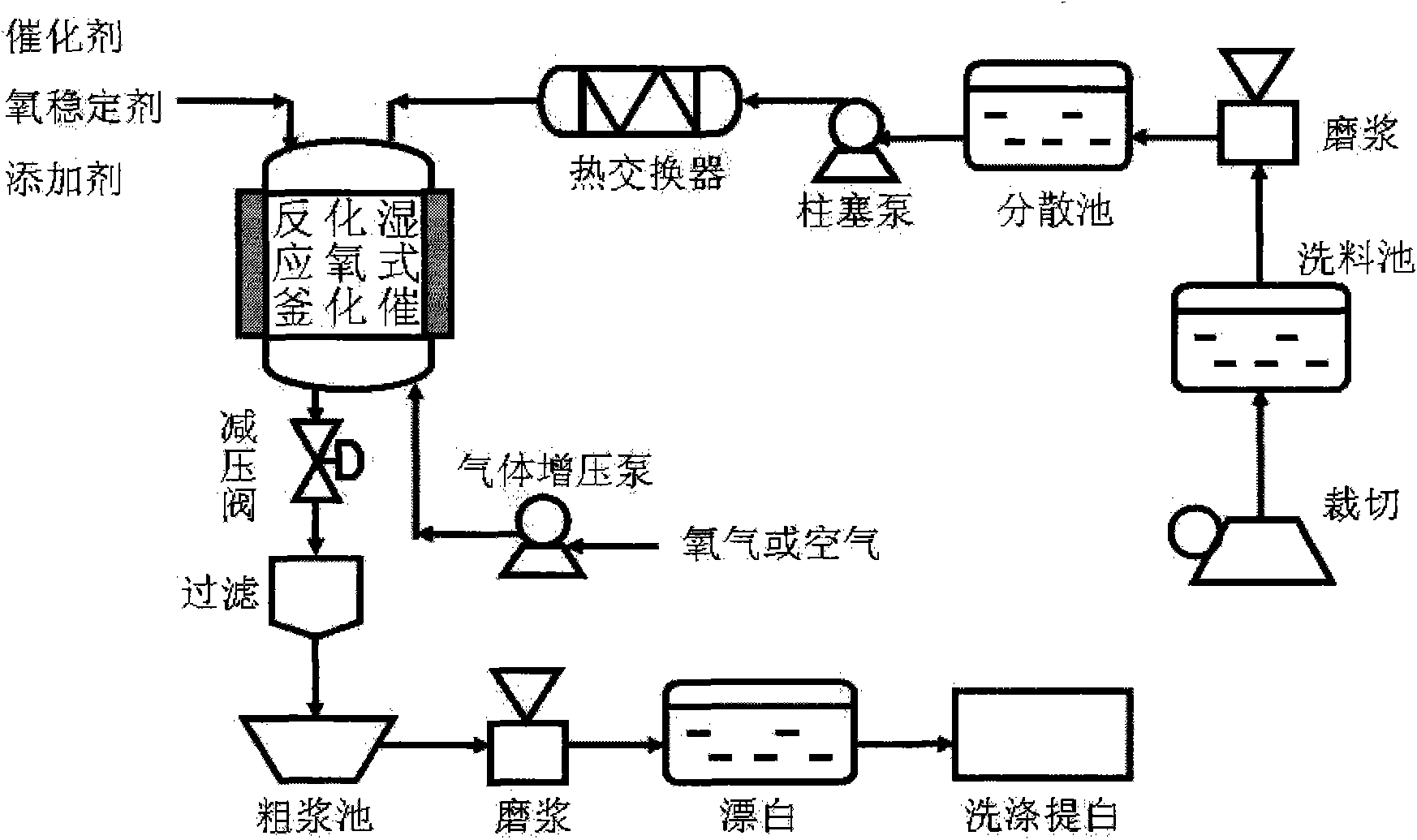

A wet catalytic oxidation and clean pulping technology, which is applied in cellulose raw material pulping, pulp bleaching, non-fibrous pulp addition, etc., can solve the problems of high pulping cost and large consumption of hydrogen peroxide, and achieve controllability of the reaction. Strong, mild oxidation conditions, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Raw material: wheat straw

[0049] After the raw materials are cut and cleaned in the washing tank, they are put into the soaking tank of the pretreatment agent and soaked for 1 hour. The pretreatment agent is a mixed solution of 15% NaOH solution and 5% EDTA aqueous solution in a weight ratio of 1:1. Then pre-grind the soaked raw materials. The pre-ground raw materials are fully dispersed in water 6 times the weight of the raw materials. After being heated by a heat exchanger, they are put into a wet catalytic oxidation reactor made of titanium alloy steel. The heating sleeve is heated up so that the temperature in the kettle reaches 200°C; the catalyst, oxygen stabilizer and additives are added through the feeding port of the reactor; the diameter of the catalyst carrier is 60mm porous ceramics, and the catalyst is 80% of the surface of the carrier sintered at a high temperature (mass percentage) of copper oxide and 20% (mass percentage) of manganese oxide; the oxygen...

Embodiment 2

[0051] Raw material: cotton stalk

[0052] After the raw materials are cut and cleaned in the washing tank, they are put into the soaking tank of the pretreatment agent and soaked for 2 hours. The pretreatment agent is a mixed solution of 20% NaOH solution and 6% EDTA aqueous solution in a weight ratio of 1:1. Then pre-grind the soaked raw materials. The pre-ground raw materials are fully dispersed in water 5 times the weight of the raw materials. After being heated by a heat exchanger, they are put into a wet catalytic oxidation reactor made of titanium alloy steel. The heating sleeve is heated up so that the temperature in the kettle reaches 240°C; the catalyst, oxygen stabilizer and additive are added through the feeding port of the reactor; the diameter of the catalyst carrier is 80mm porous ceramics, and the catalyst is 85% (mass) of the surface of the carrier sintered at a high temperature. percentage) of copper oxide and 15% (mass percentage) of manganese oxide; the oxy...

Embodiment 3

[0054] Raw material: reed

[0055] After the raw materials are cut and cleaned in the washing tank, they are put into the soaking tank of the pretreatment agent and soaked for 1.5 hours. The pretreatment agent is a mixed solution of 15% NaOH solution and 5% EDTA aqueous solution in a weight ratio of 1:1. Then pre-grind the soaked raw materials. The pre-ground raw materials are fully dispersed in water 5 times the weight of the raw materials. After being heated by a heat exchanger, they are put into a wet catalytic oxidation reactor made of titanium alloy steel. The heating sleeve is heated up so that the temperature in the still reaches 220°C; the catalyst, oxygen stabilizer and additives are added through the feeding port of the reaction kettle; the diameter of the catalyst carrier is 60mm porous ceramics, and the catalyst is 80% of the surface of the carrier sintered at a high temperature (mass percentage) of copper oxide and 20% (mass percentage) of manganese oxide; the oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com