Method for preventing profiled steel plate from hydrogen fluoride corrosion and structure thereof

A profiled steel plate and hydrogen fluoride technology, applied in chemical instruments and methods, anti-corrosion coatings, devices for coating liquid on the surface, etc., can solve problems that affect the service life of profiled steel plate roofs, corrode profiled steel plates, and electrolytic aluminum explosions, etc. , to achieve good UV resistance and acid resistance, prolong service life, and not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

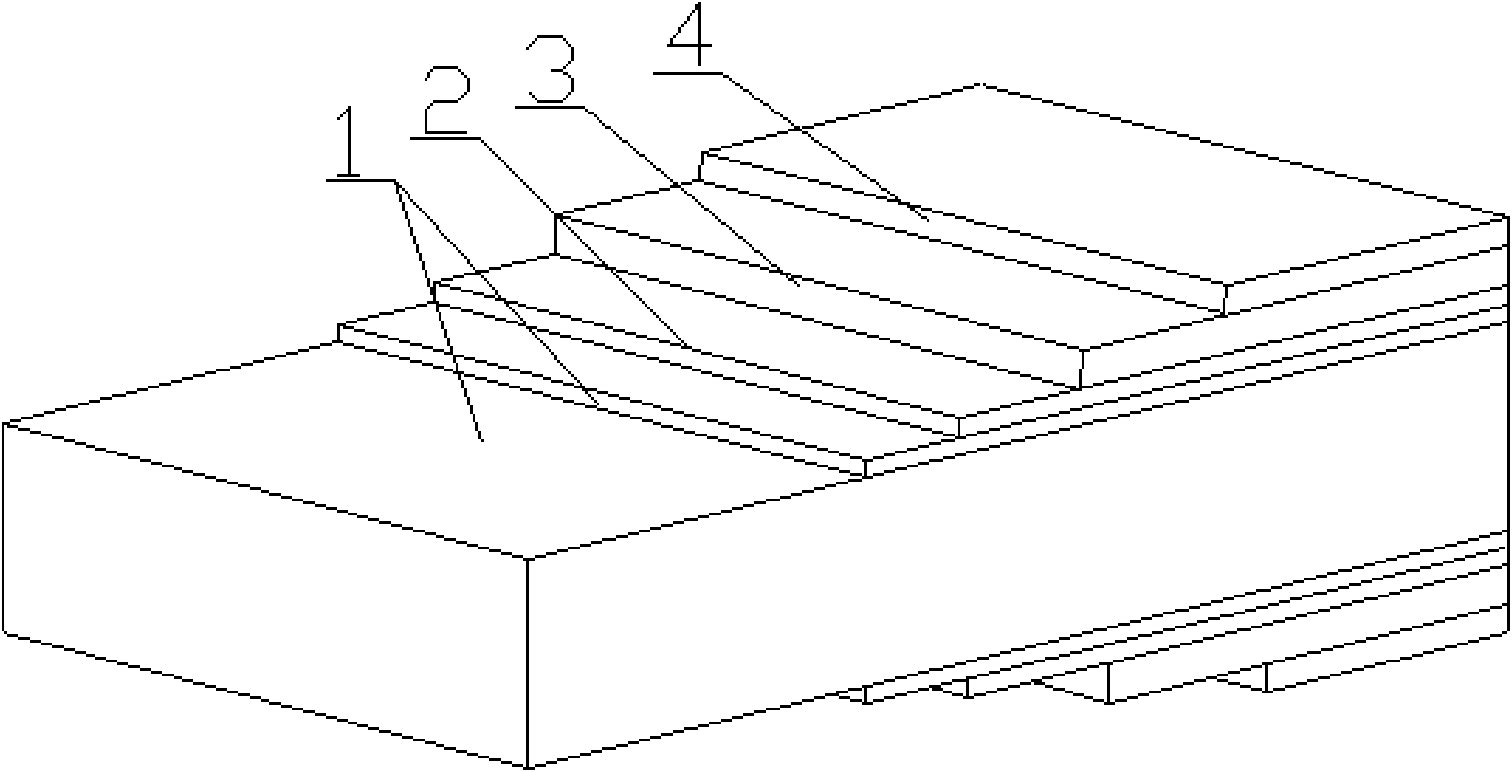

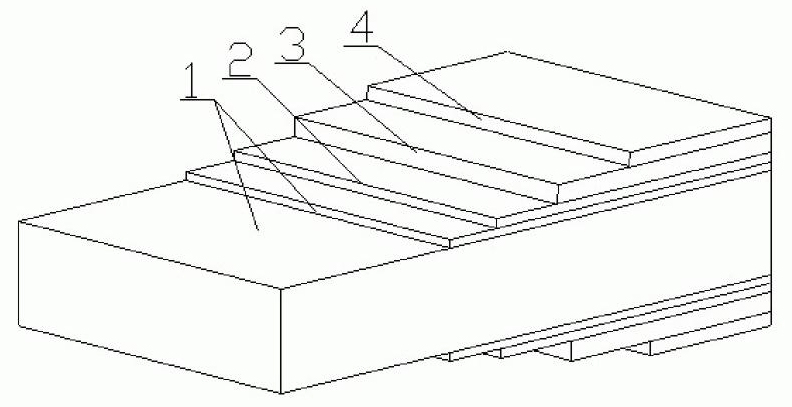

[0015] Embodiment of the present invention: the substrate 1 is subjected to rust removal and cleaning pretreatment, and the substrate 1 can be cleaned with a rust remover, or the rust removal treatment such as sandblasting can reach the international standard st 3 class. Then spray surface treatment agent 2, what is the surface treatment agent? ? , to supplement the dilution ratio. The surface treatment agent is a modified epoxy vinyl resin and barium sulfate powder in a ratio of 10:1, then add acetone to dilute, and the diluted ratio is prepared by 8% by weight, that is, acetone is 92%, modified ethylene oxide Base resin and barium sulfate powder are 8%. Spray phenolic resin anticorrosion paint 3 again, and then spray fluorocarbon paint 4 after drying for 24 hours. Partial anti-corrosion treatment is carried out after installation. Local anti-corrosion treatment refers to spot repair treatment with modified epoxy anti-corrosion paint and fluorocarbon paint on the screw pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com