Bone repair implant coated with strontium-doped calcium polyphosphate coating and preparation method thereof

A strontium calcium polyphosphate and bone repair technology, applied in coatings, prostheses, dental preparations, etc., can solve problems such as poor biocompatibility, poor combination of biological tissue and matrix, and achieve good high temperature stability and good biological activity , Strong osteoinductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

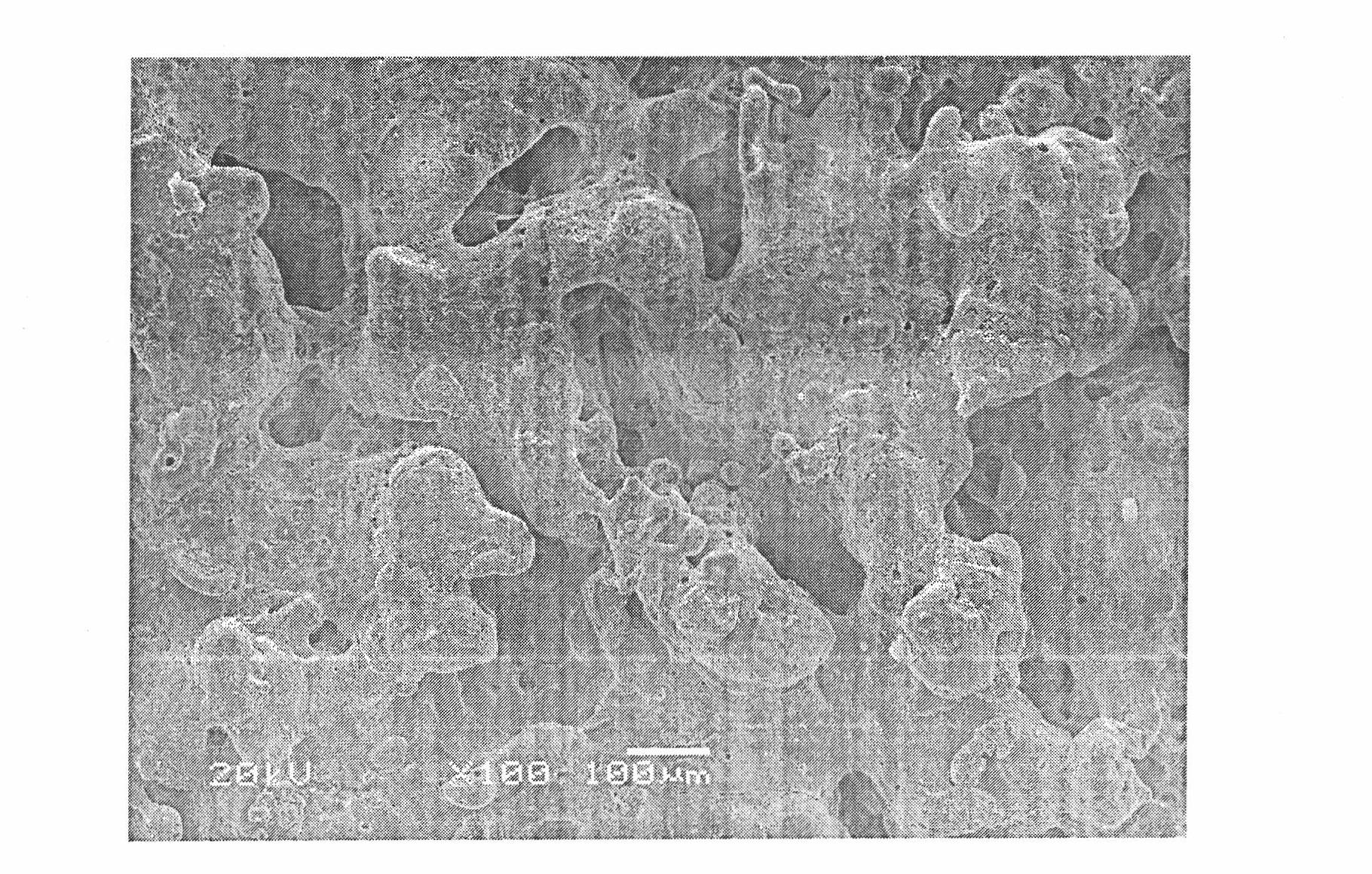

Embodiment 1

[0032] (1) Weigh the required CaCO according to the molar ratio of calcium to strontium 98:2 3 , SrCO 3 (analytical pure) and the amount of phosphoric acid (85%), wet preparation of hydrated calcium dihydrogen phosphate (Ca(H2PO4) 2 ·H 2 O, referred to as CPMM) solution, using a rotary evaporator to steam the CMPP powder. Heat the dried CMPP powder to about 500°C to heat-preserve and polymerize to form strontium-doped calcium polyphosphate (SCPP), then raise the temperature to about 1200°C to obtain SCPP melt, quench in ice water to obtain amorphous SCPP burnt material, dry and grind to obtain Pass 100 mesh powder, heat the powder to about 700°C and keep it warm for about 4 hours to obtain β-SCPP, and then grind it for the second time after natural cooling, take 150 mesh-300 mesh (50-100μm) β-SCPP powder for spraying .

[0033] (2) After roughening the surface of the titanium substrate, the spraying process parameters are shown in Table 1:

[0034] Table 1

[0035] ...

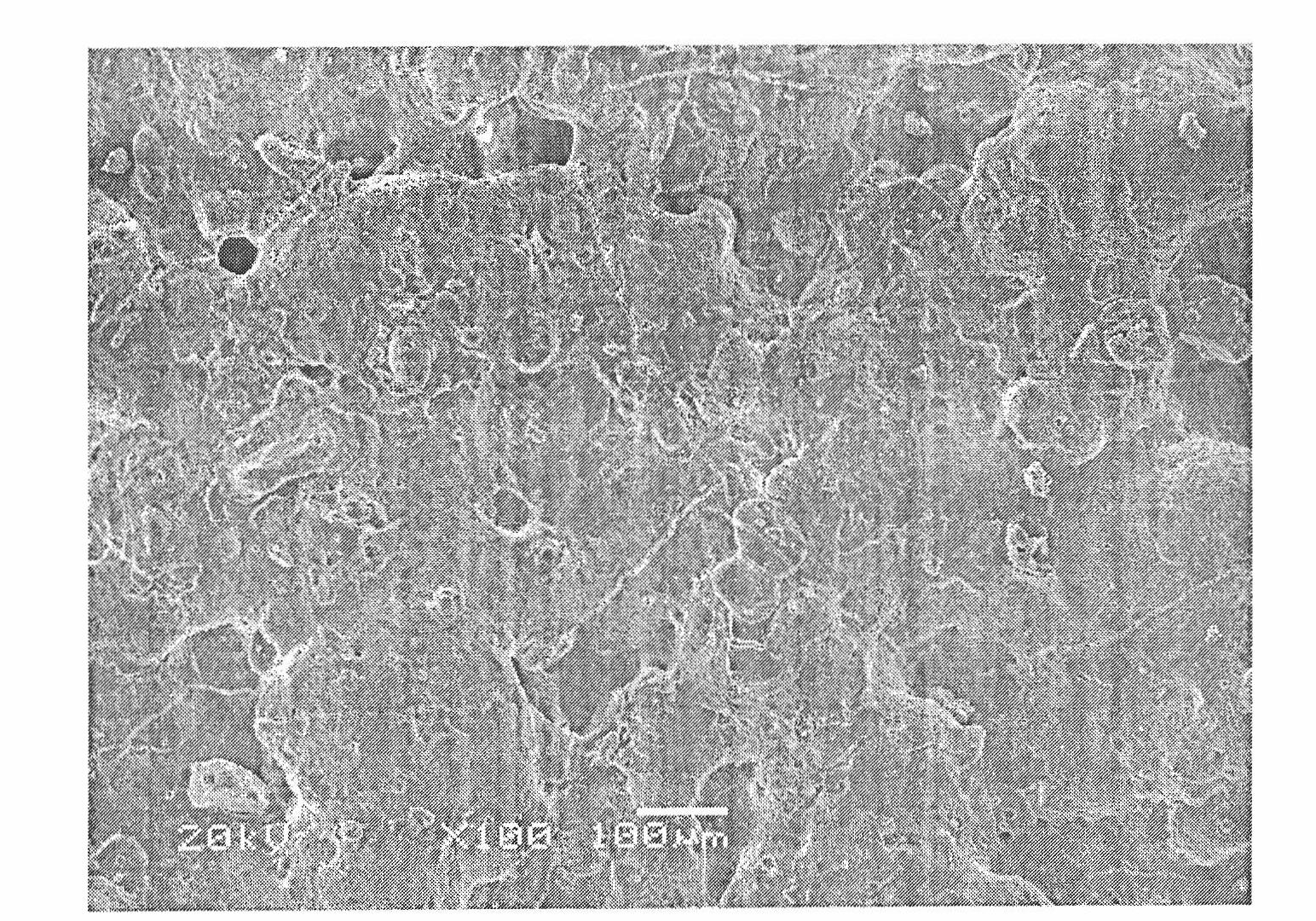

Embodiment 2

[0040] (1) Weigh the required CaCO according to the molar ratio of calcium to strontium 99:1 3 , SrCO 3 (analytical pure) and the amount of phosphoric acid (85%), wet preparation of hydrated calcium dihydrogen phosphate (Ca(H2PO4) 2 ·H 2O, CPMM) solution, use the rotary evaporator to steam the CMPP powder. Heat the dried CMPP powder to about 500°C to heat-preserve and polymerize to generate SCPP, then raise the temperature to about 1200°C to obtain SCPP melt, quench in ice water to obtain amorphous SCPP burnt, and grind to obtain over 100 mesh powder after drying. Heat the powder to 750°C and keep it warm for about 4 hours to obtain β-SCPP. After cooling down naturally, grind it for the second time. Take 150-300 mesh (50-100μm) powder for spraying.

[0041] (2) After roughening the surface of the titanium substrate, the spraying process parameters are shown in Table 2:

[0042] Table 2

[0043] Current (A)

400

Voltage (V)

62

working atm...

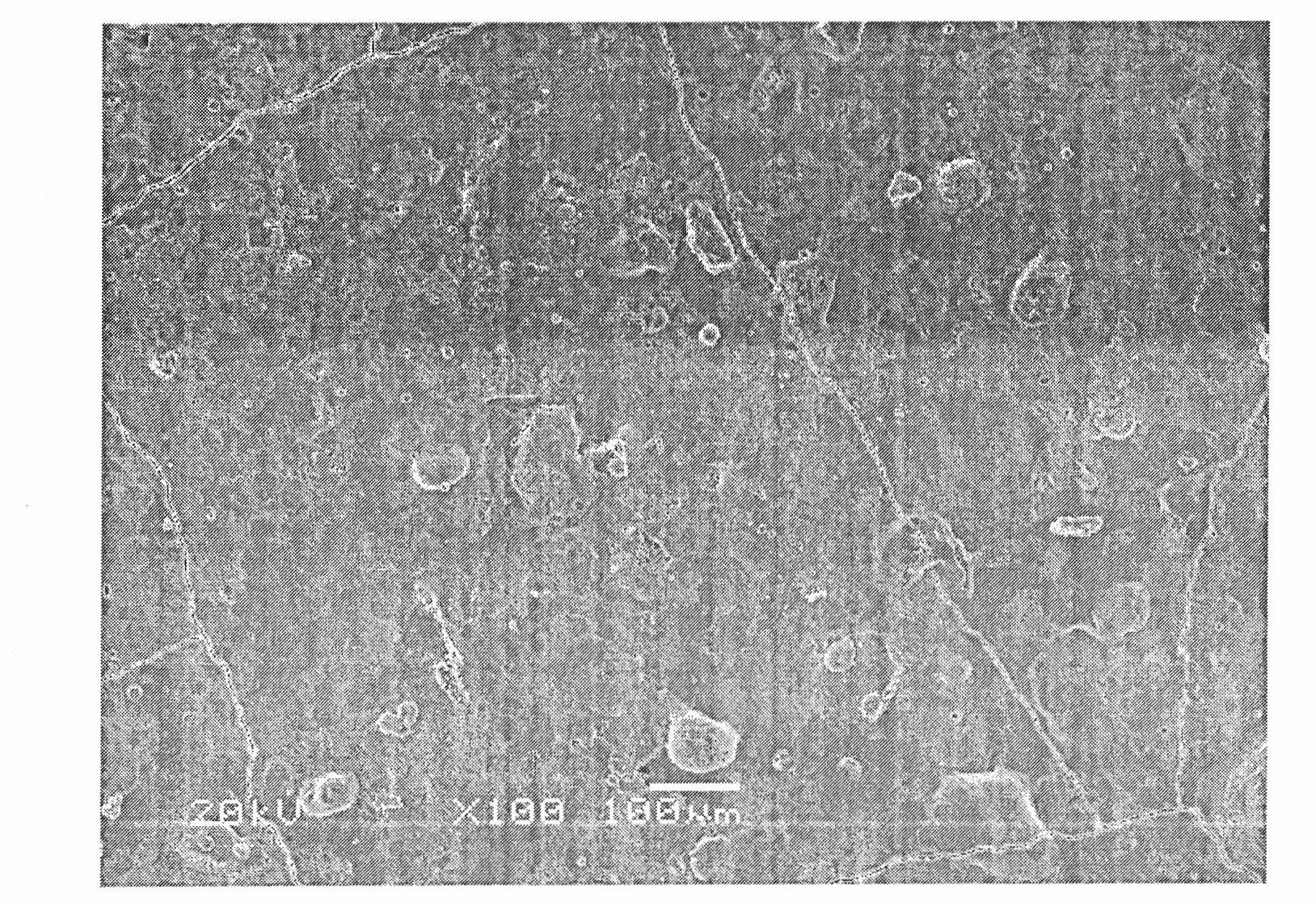

Embodiment 3

[0047] (1) Weigh the required CaCO according to the molar ratio of calcium to strontium 95:5 3 , SrCO 3 (analytical pure) and the amount of phosphoric acid (85%), wet preparation of hydrated calcium dihydrogen phosphate (Ca(H2PO4) 2 ·H 2 O, CPMM) solution, use the rotary evaporator to steam the CMPP powder. Heat the dried CMPP powder to about 500°C to heat-preserve and polymerize to generate SCPP, then raise the temperature to about 1200°C to obtain SCPP melt, quench in ice water to obtain amorphous SCPP burnt, and grind to obtain over 100 mesh powder after drying. Heat the powder to about 800°C and keep it warm for about 3.5 hours to obtain β-SCPP. After cooling down naturally, grind it for the second time, and take 150-300 mesh (50-100μm) powder for spraying.

[0048] (2) After roughening the surface of the titanium substrate, the spraying process parameters are shown in Table 3:

[0049] table 3

[0050] Current (A)

450

Voltage (V)

66.7

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com