Method for preparing nitrogen oxide phosphor powder

A technology of nitrogen oxides and phosphors, which is applied in the field of phosphor powder preparation, can solve the problems of increasing the difficulty of preparation, and achieve the effects of increasing the difficulty of preparation, good uniformity, and good product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

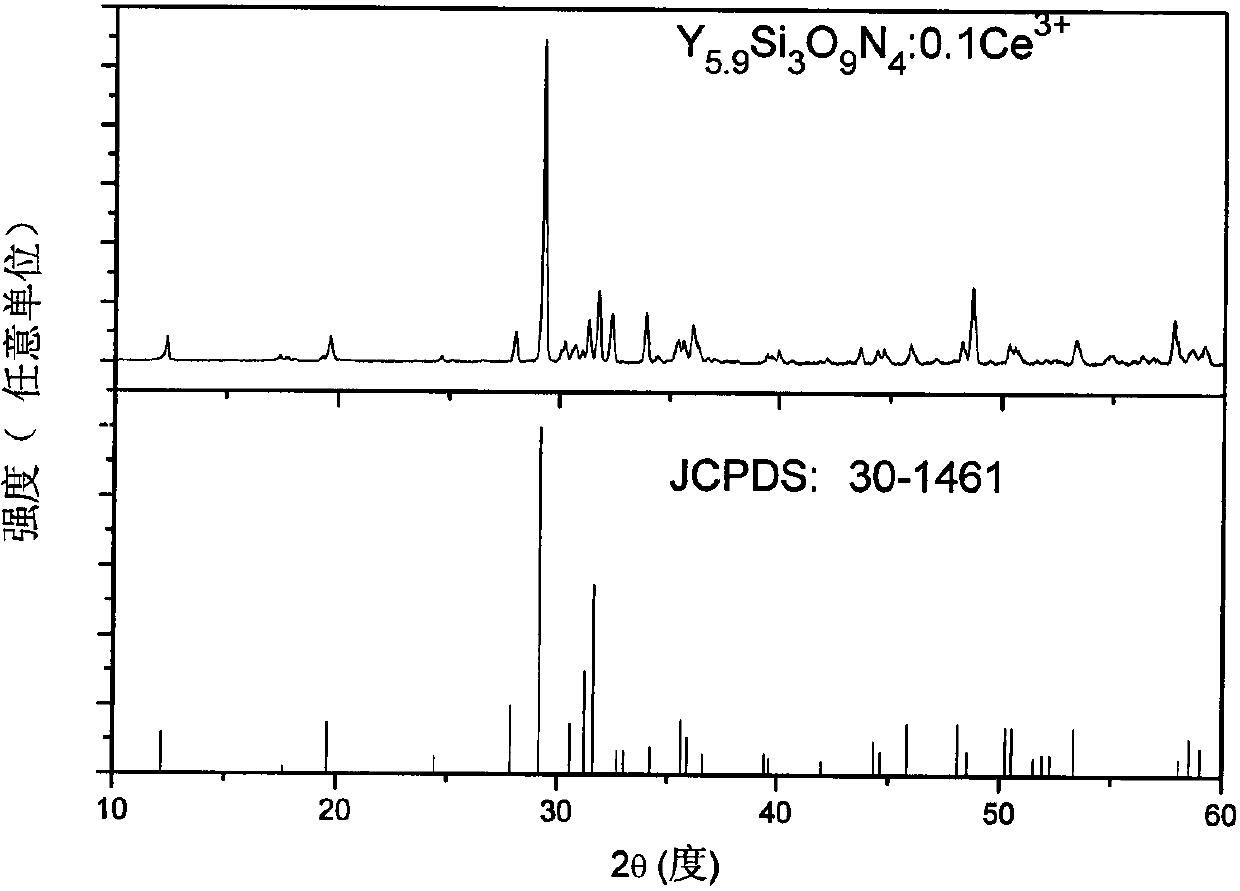

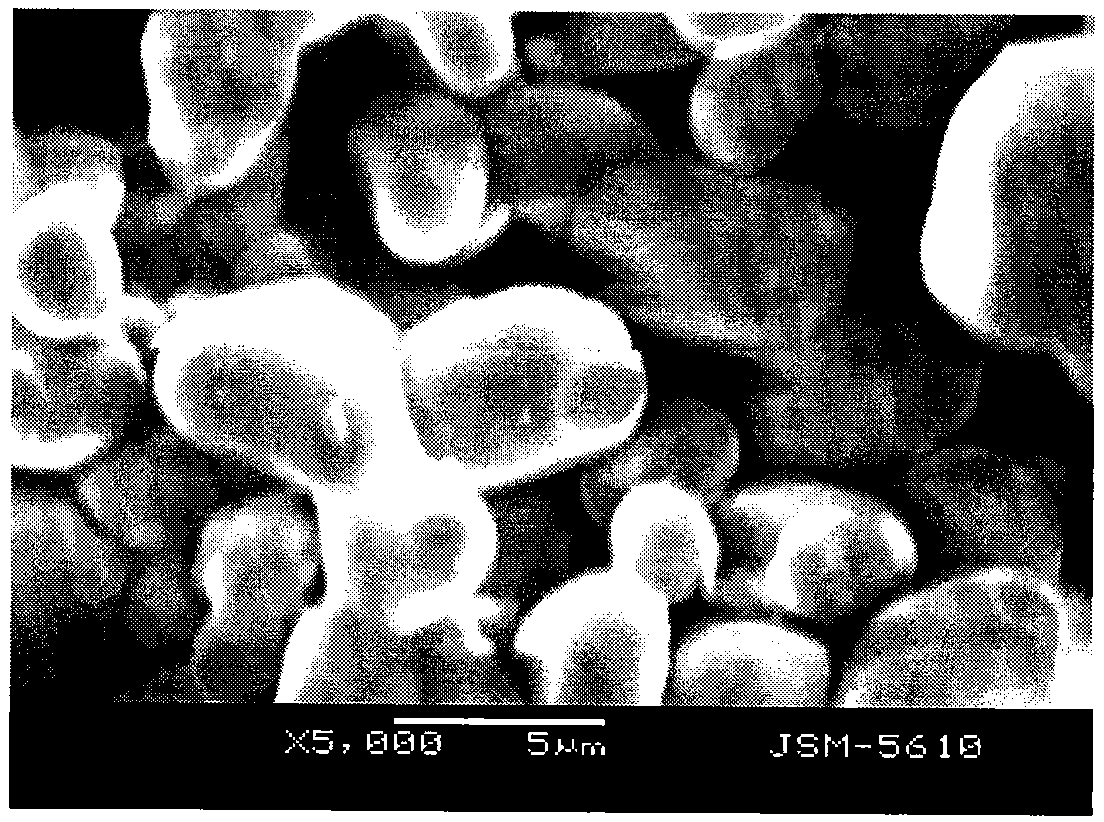

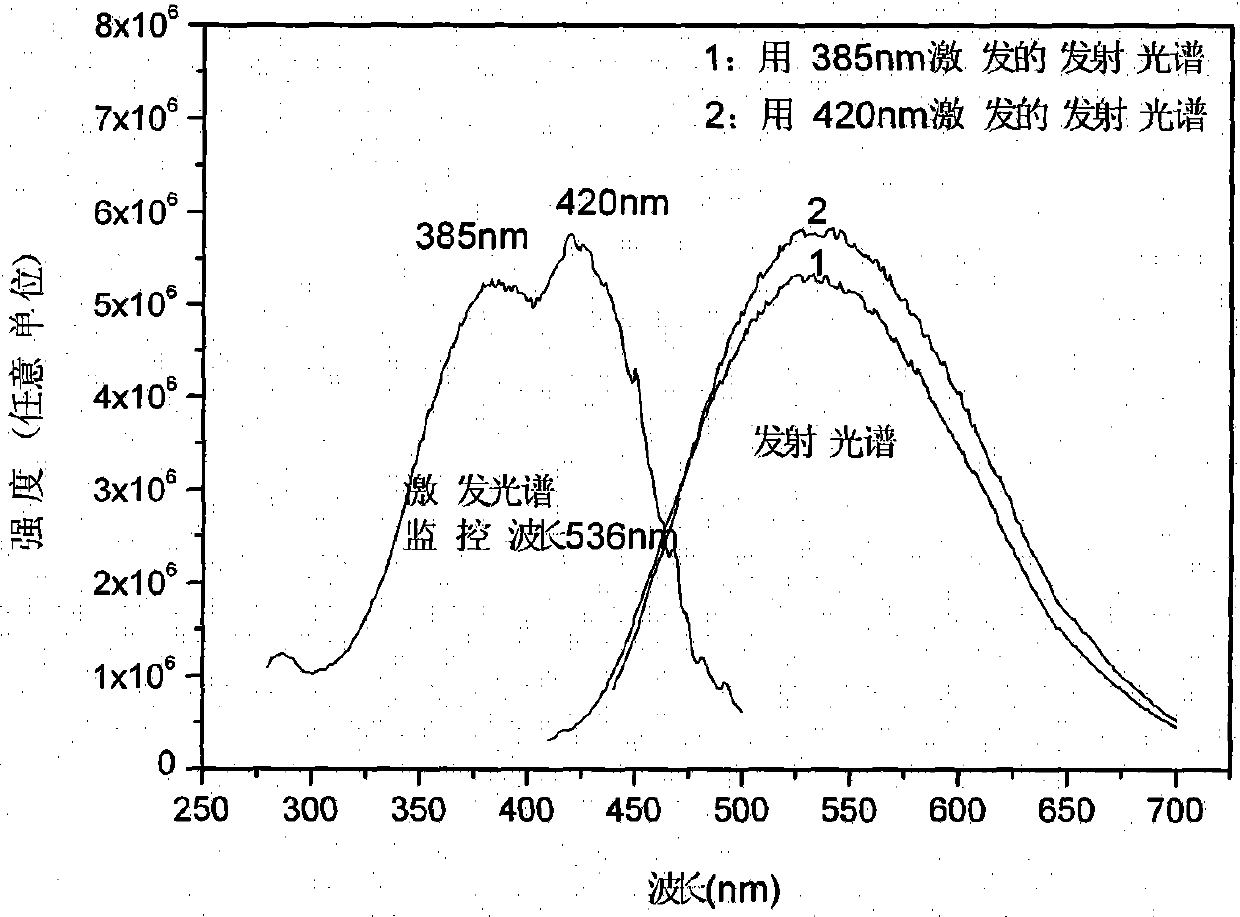

[0028] In the present embodiment, the nitrogen oxide fluorescent powder to be prepared is (Y 5.9 Ce 0.1 ) Si 3 o 9 N 4 , where the metal components are Y and Ce, and the nitride is Si 3 N 4 . According to (Y 5.9 Ce 0.1 ) Si 3 o 9 N 4 Weigh the nitrate Y of Y (NO 3 ) 3 ·6H 2 O(AR) 22.5976 g, Ce nitrate Ce(NO 3 ) 3 ·6H 2 O (99.99%) 0.4342 g and nitride Si 3 N 4 (AR) 1.4028 g, dissolved in distilled water, mixed thoroughly to make 100ml milky white suspension A; add 5ml polyethylene glycol to suspension A, stir well to obtain suspension B; add ammonia water dropwise to adjust suspension B Keep the pH at 6. The suspension B was ultrasonically oscillated for 30 minutes to obtain a uniform and stable suspension C; the suspension C was placed in a muffle furnace and heat-treated at 500°C for 2 hours to obtain the precursor powder D ; Precursor powder D is packed in a graphite crucible, and is calcined in a reducing atmosphere at a temperature of 1300°C for 7 hours, ...

Embodiment 2

[0030] In the present embodiment, the nitrogen oxide fluorescent powder to be prepared is (Y 5.5 Ce 0.5 ) Si 3 o 9 N 4 , where the metal components are Y and Ce, and the nitride is Si 3 N 4 , according to (Y 5.5 Ce 0.5 ) Si 3 o 9 N 4 Weigh the hydrochloride YCl of Y 3 ·6H 2 O(AR) 25.0272 g, the hydrochloride CeCl of Ce 3 ·6H 2 O (99.99%) 2.6590 g and nitride Si 3 N 4 (AR) 2.1042 g, dissolved in distilled water, mixed thoroughly to make 100ml milky white suspension A; add 5ml polyethylene glycol to suspension A, stir well to obtain suspension B, then add ammonia water dropwise to adjust the suspension B, and maintain the pH of suspension B at 6. The suspension B was ultrasonically oscillated for 30 minutes to obtain a uniform and stable suspension C; the suspension C was placed in a muffle furnace and heat-treated at 500°C for 2.5 hours to obtain the precursor powder D ; Precursor powder D is packed in a graphite crucible, and calcined in a reducing atmosphere ...

Embodiment 3

[0032] In this embodiment, the nitrogen oxide phosphor to be prepared is (Sr 0.9 Yb 0.1 )SiAl 2 N 2 o 3 , where the metal components are Sr, Al and Yb, and the nitride is Si 3 N 4 and AlN, according to (Sr 0.9 Yb 0.1 )SiAl 2 N 2 o 3 Weigh the Sr nitrate Sr(NO 3 ) 2 (AR) 5.7140 grams, Al nitrate Al (NO 3 ) 3 ·6H 2 O(AR) 15.0056 g, the nitrate of Yb Yb(NO 3 ) 3 ·5H 2 O (99.99%) 1.3474 g, nitride Si 3 N 4 (AR) 1.4028 g, nitride AlN (AR) 0.8198 g, dissolved in distilled water, mixed thoroughly to make 100 ml milky white suspension A; add 8 ml polyethylene glycol to suspension A, stir well, to obtain suspension B , drop ammonia water, adjust the pH value of the solution, and keep the pH value of Suspension B at 6. The suspension B was ultrasonically oscillated for 30 minutes to obtain a uniform and stable suspension C; the suspension C was placed in a muffle furnace and heat-treated at 500°C for 3 hours to obtain the precursor powder D ; Precursor powder D is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com