CSP process-based manufacturing method of economical hot-rolled dual-phase steel with high surface quality

A technology of hot-rolled dual-phase steel and manufacturing method, which is applied in the direction of workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., which can solve the problems of iron oxide scale defects, increase the control stability of structure performance, and low cooling capacity, and achieve the goal of structure Stable performance control, stable control of organizational performance, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1) The chemical composition of the steels in Examples 1-3 and Comparative Example is shown in Table 1.

[0030] Table 1 Melting composition of Examples 1-3 and Comparative Example (wt, %)

[0031] Example C Si mn S P als 1 0.030 0.45 1.20 0.001 0.010 0.015 2 0.045 0.50 1.42 0.001 0.011 0.0387 3 0.065 0.55 1.55 0.001 0.008 0.060 comparative example 0.060 0.70 1.50 0.001 0.013 0.050

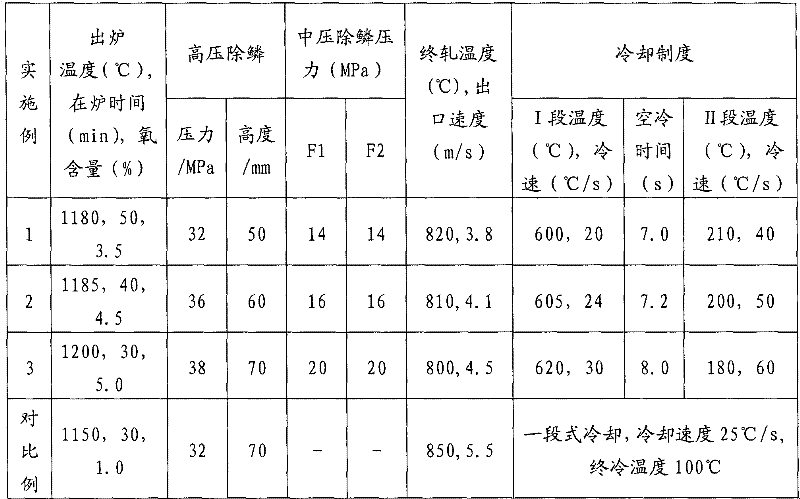

[0032] The steel of the chemical composition of Examples 1 to 3 listed in Table 1 is taken as a raw material through molten iron desulfurization, converter blowing, argon blowing, LF furnace refining, continuous casting, and rotary descaling device descaling (produced by SMS company in Germany, Example 1-3 Control rotary descaling pressure (45MPa, 43MPa, 40MPa respectively), soaking furnace soaking, high pressure descaling, finishing rolling (medium pressure descaling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com