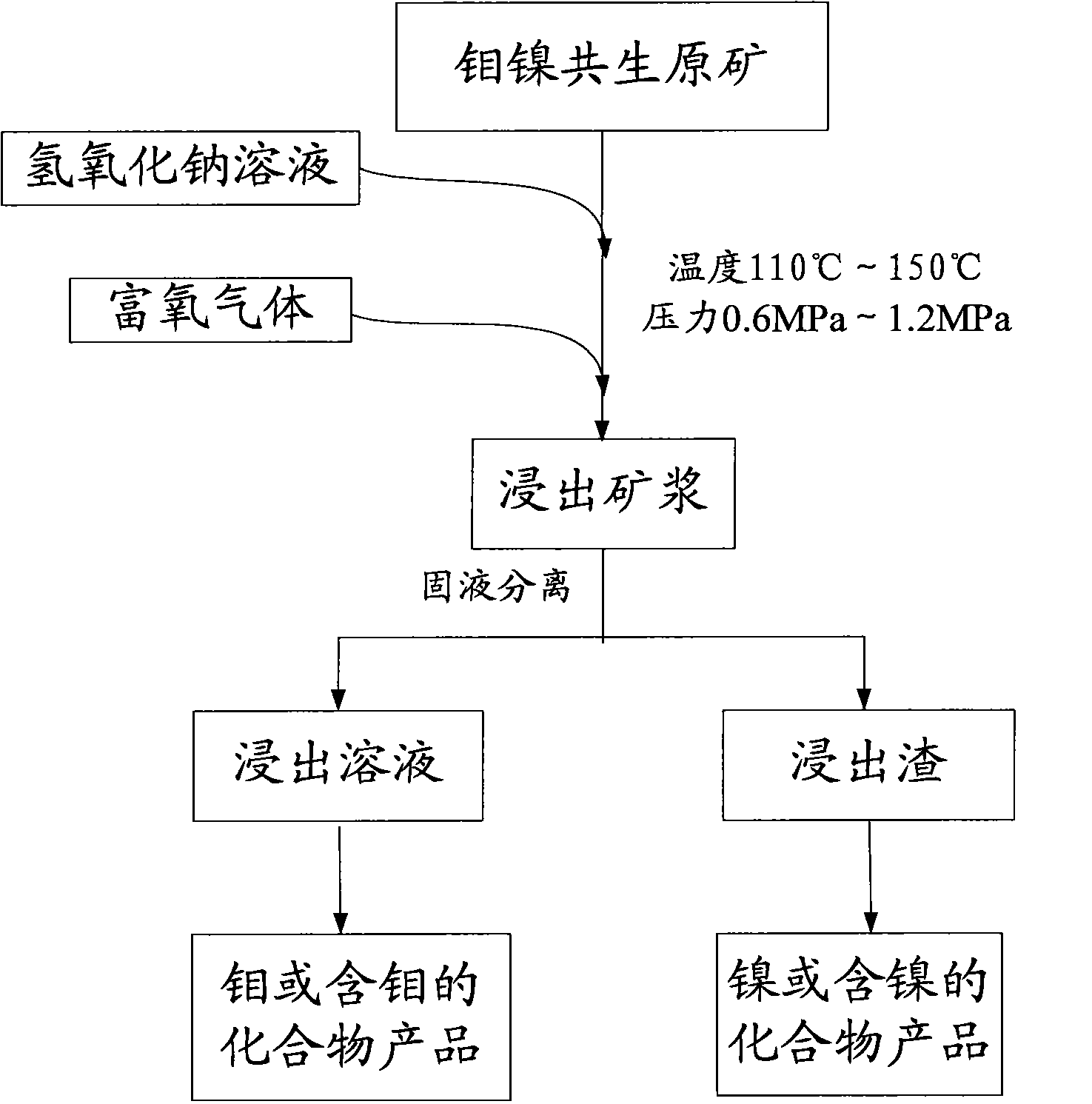

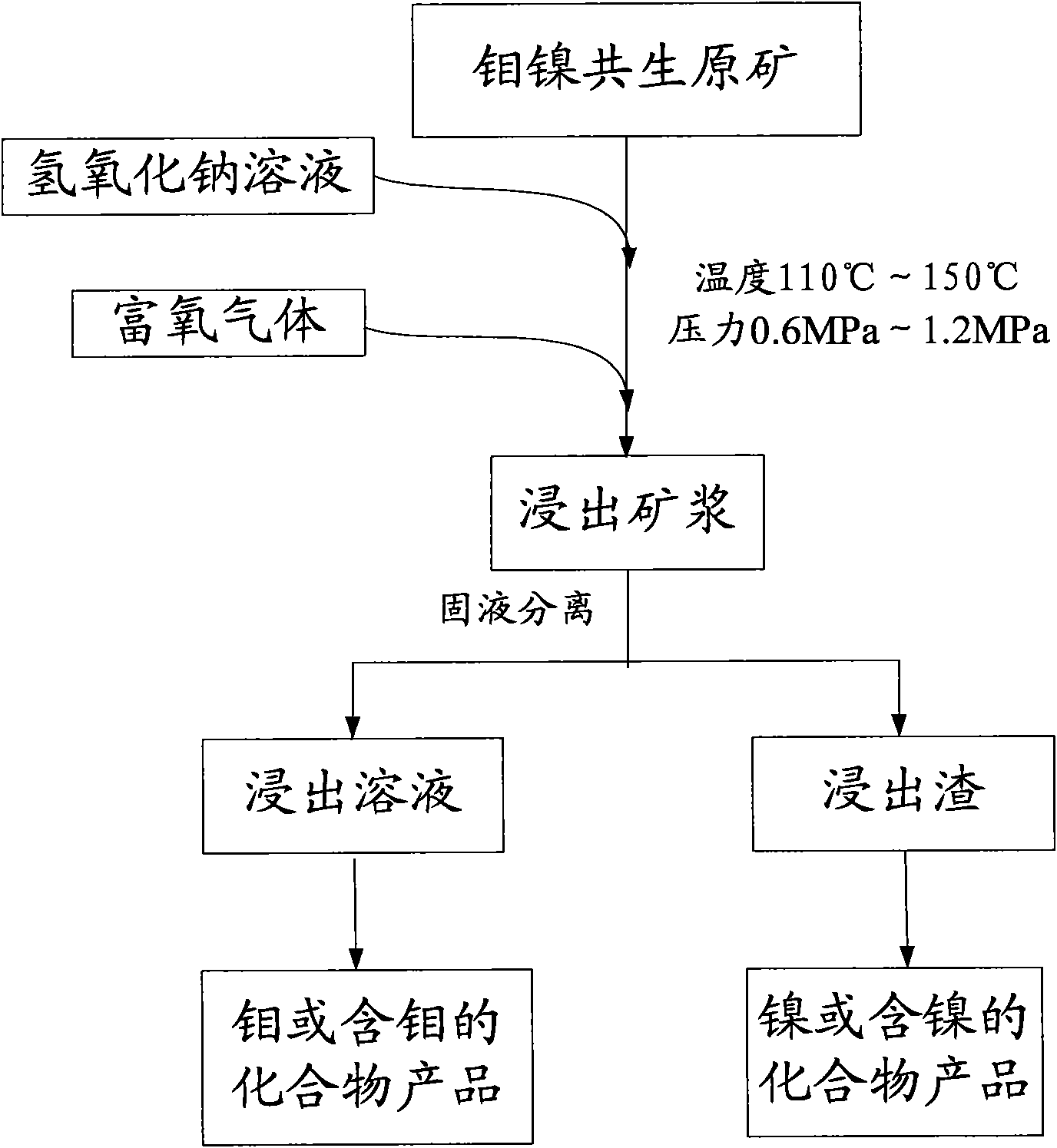

Pressure leaching method of molybdenum-nickel paragenetic raw ore

A molybdenum-nickel and leaching technology is applied in the field of pressurized oxidation and alkali leaching to treat molybdenum-nickel symbiotic raw ore, which can solve the problems of low recovery rate of molybdenum and nickel, low production efficiency and high production cost, and achieve environmental friendliness and alkali concentration. Low, effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

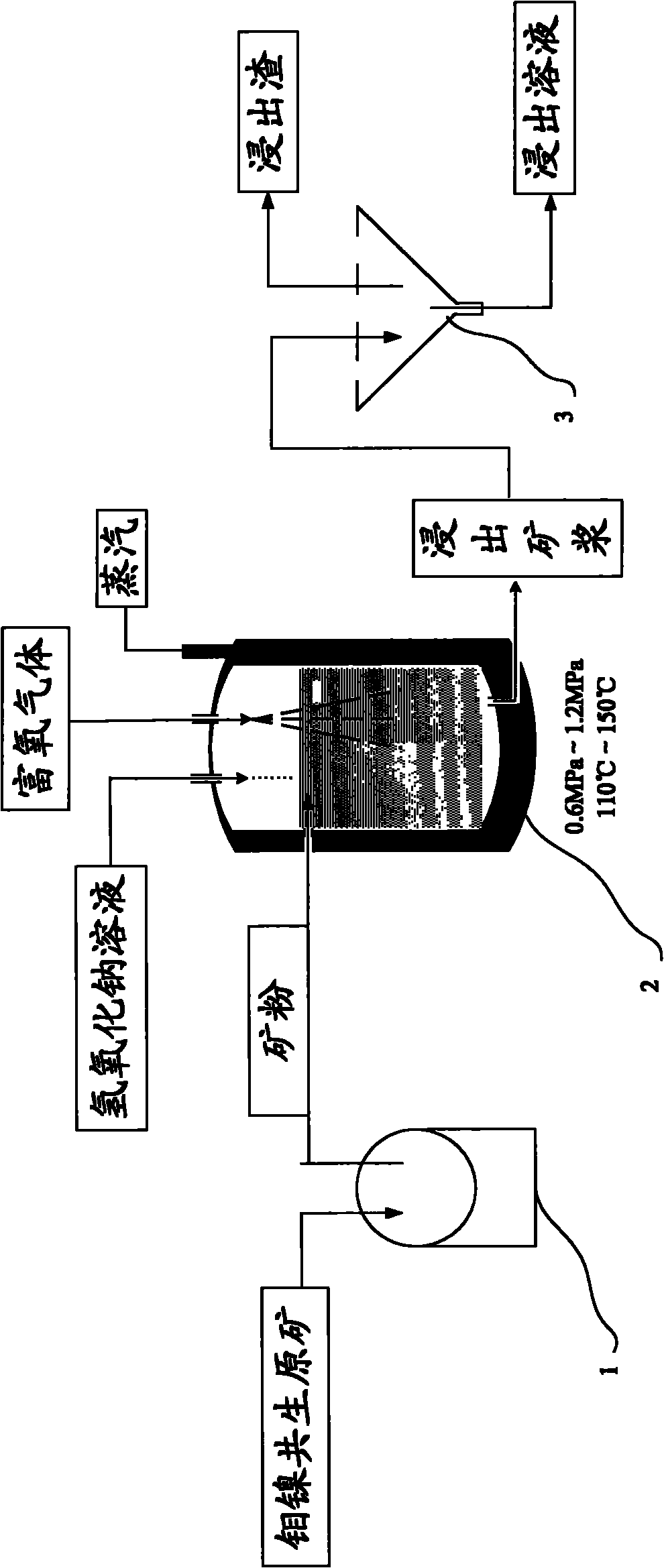

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, the molybdenum-nickel symbiotic raw ore composition used is as follows: Mo 4.0%, Ni 4.0%, and 90% of the molybdenum-nickel symbiotic raw ore is finely ground and passed through a 0.044mm sieve.

[0041] Add the finely ground molybdenum-nickel symbiotic raw ore powder and 9wt% sodium hydroxide solution into the reaction vessel at a liquid-solid ratio of 3:1. After sealing the reaction vessel cover, start heating with steam to heat up, and start stirring and ventilation at the same time. Oxygen at a concentration of 92 vol% was introduced to make the pressure in the reaction vessel 0.6 MPa, and the temperature reached 110° C., and the temperature was maintained for 120 minutes. After leaching, close the intake valve and open the exhaust valve. After cooling to 90°C with cooling water, open the discharge port to release the leached pulp. After solid-liquid separation, the leaching solution undergoes conventional purification—ion exchange—desorption—trans...

Embodiment 2

[0044] In this embodiment, the molybdenum-nickel symbiotic raw ore composition used is as follows: Mo 5.0%, Ni 0.7%, and 90% of the molybdenum-nickel symbiotic raw ore is finely ground and passed through a 0.044mm sieve.

[0045] Add the finely ground molybdenum-nickel symbiotic ore powder and 11wt% sodium hydroxide solution into the reaction vessel at a liquid-to-solid ratio of 4:1, seal the cover of the reaction vessel, start heating with steam, and start stirring and ventilation at the same time. Oxygen at a concentration of 93vol% was introduced to make the pressure in the reaction vessel 0.8MPa; after the temperature reached 120°C, the temperature was maintained for 105 minutes. After leaching, close the oxygen inlet valve and open the exhaust valve. After cooling to 92°C with cooling water, open the discharge port to release the leached pulp. After solid-liquid separation, the leaching solution undergoes conventional purification—ion exchange—desorption—transformation—eva...

Embodiment 3

[0048] In this embodiment, the composition of the molybdenum-nickel symbiotic raw ore used is as follows: Mo6.0%, Ni2.1%, and 90% of the molybdenum-nickel symbiotic raw ore is finely ground and passed through a 0.044mm sieve.

[0049] Add the finely ground molybdenum-nickel symbiotic ore powder and 12wt% sodium hydroxide solution into the reaction vessel at a liquid-to-solid ratio of 4:1. Oxygen with a concentration of 94vol% makes the pressure in the reaction vessel 1.0 MPa; after the temperature reaches 130° C., it is kept for 90 minutes. After leaching, close the oxygen inlet valve and open the exhaust valve, cool to 95°C with cooling water, open the discharge port, release the leached pulp, and separate the solid and liquid. Molybdenum oxide is produced from the leaching solution through conventional purification-ion exchange-desorption-transformation-evaporation and crystallization; the leaching slag is used as the raw material for nickel smelting.

[0050] The indicator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com