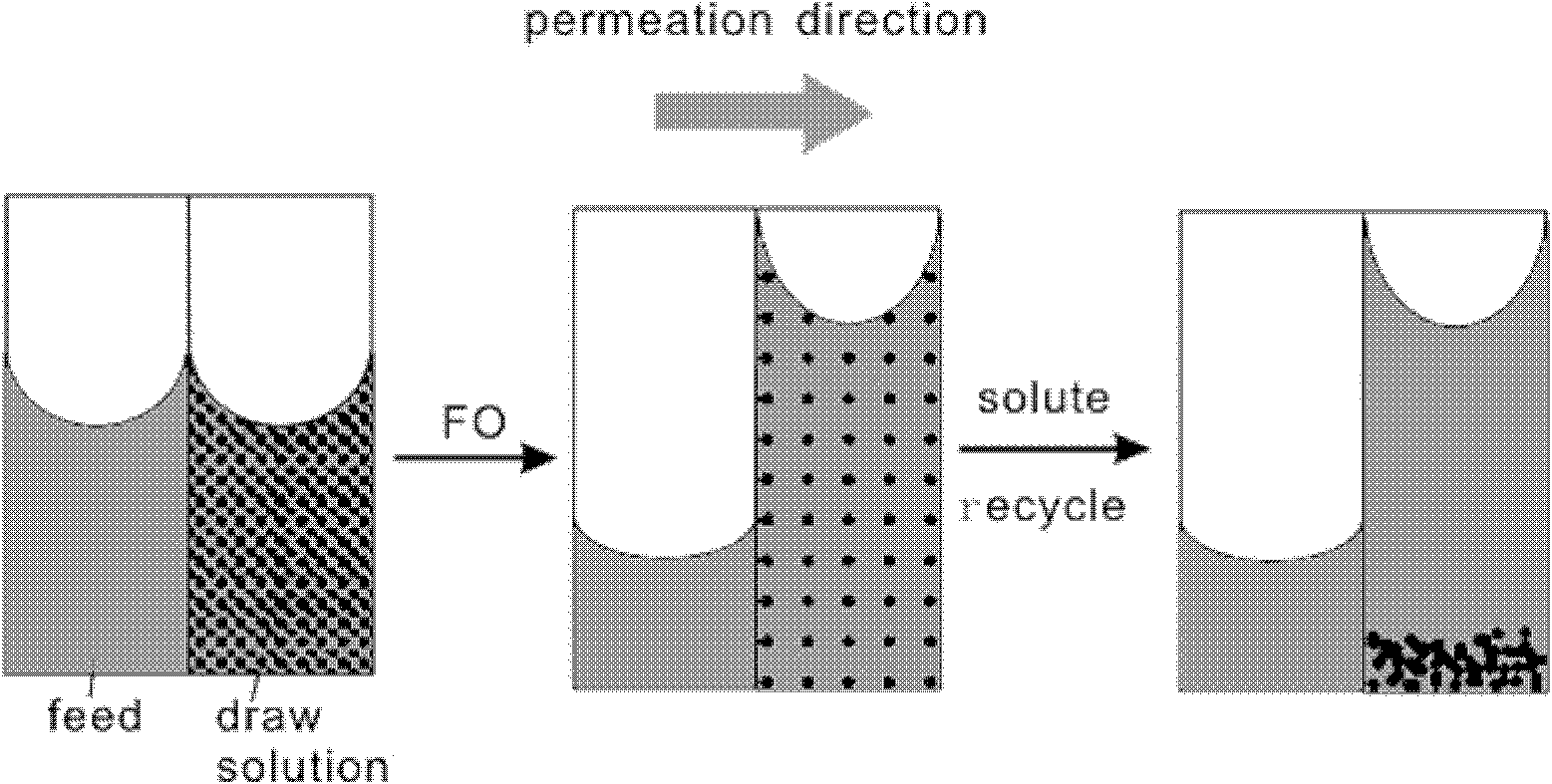

Composite fine particles of forward osmosis driving solution system and application thereof

A driving solution and forward osmosis technology, applied in the direction of osmosis/dialysis water/sewage treatment, etc., can solve the problems of low osmotic pressure, low water permeation efficiency, poor long-term stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Sulfonated polystyrene beads (SPS) drive solution: Add 200 g of deionized water into a three-necked flask, then mechanically stir and raise the temperature of the water bath to 85°C. Add 20g of sodium p-styrene sulfonate into a three-necked flask, stir and mix evenly. Weigh 0.1 g of ammonium persulfate and dissolve it in 10 g of deionized water, and then add it into the above-mentioned three-necked flask. Condensed and refluxed for 24h. Sulfonated polystyrene (SPS) is obtained. Water-soluble sulfonated polystyrene microspheres (SPSS, diameter range 10-20 microns) were obtained after centrifugation. Get 15 grams of SPSS, dissolve it in 85 grams of water and prepare a drive solution containing fine particles, use a CA membrane (cellulose acetate membrane material) as a permeable membrane, and after 18 hours, the permeability of the membrane measured is 15kg / m 2 h. Solvent systems include water, methanol, ethanol, propanol, butanol, pentanol, ethylene glycol, glycerol,...

Embodiment 2

[0062] Carboxylated polystyrene microsphere drive solution

[0063] Add 90 g of deionized water into the three-necked flask, then mechanically stir and raise the temperature of the water bath to 85°C. Add 3g of acrylic acid and 10g of styrene into a three-necked flask, stir and mix evenly. Weigh 0.1 g of ammonium persulfate and dissolve it in 10 g of deionized water, and then add it into the above-mentioned three-necked flask. Condensed and refluxed for 24h. A carboxylated polystyrene emulsion is obtained. Titration with sodium hydroxide and centrifugation gave the sodium salt of water-soluble carboxylated polystyrene microspheres (PSA). Particle size analysis determined a sphere size of 150 nm. Weigh 10 grams of dry PSA sodium salt and dissolve it in 90 grams of water to be used as the drive solution for forward osmosis. Using the CA membrane as the permeable membrane, the permeability of the membrane was measured to be 10kg / m in 18 hours 2 h. The fine particles are rec...

Embodiment 3

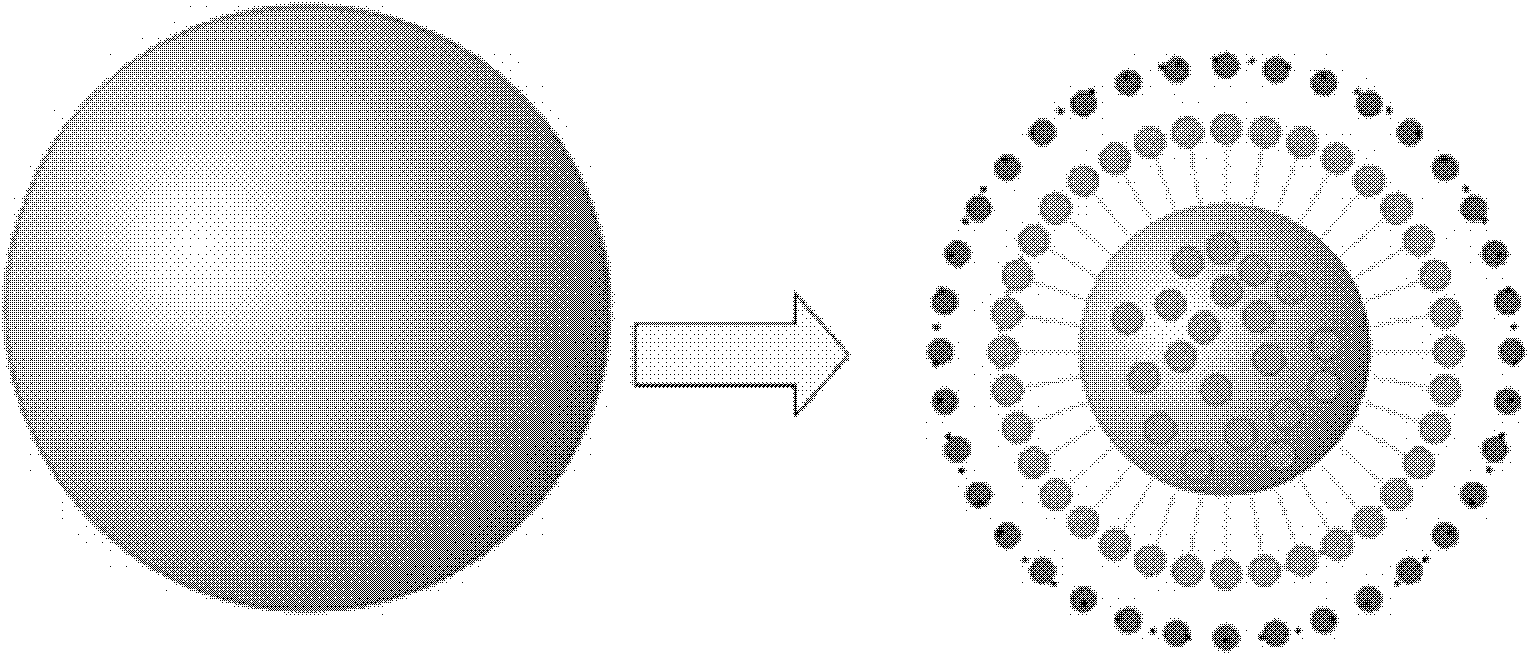

[0065] Fe3O4 or Fe2O3 fine pellets

[0066] FeCl 2 and FeCl 3 The molar ratio is 1:2 as the raw material, dissolved in deionized water, adding PEG-400, when heated to 60 degrees, adding NaOH solution while electric stirring, and reacting for 30 minutes to obtain fine ferric iron tetroxide with a particle size of 9 nanometers fine particles. The reaction solution was taken out and washed once with deionized water, magnetically sucked to remove impurities, and modified with aminopropyltriethoxysilane (APTES) to obtain amino-modified SPION. The nanoparticles are further reacted with methyl bromide to obtain quaternized ammonium salts. The material is repeatedly deposited with anionic sulfonated macromolecule and cationic polymer polyallylamine hydrochloride to obtain stable polyelectrolyte-wrapped superparamagnetic fine particles (with a diameter range of 30-100 nanometers). 10 grams of superparamagnetic fine particles are dissolved in 90 grams of water. Using CA membrane as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com