Carbon-based nano novel field electron emission material in areatus layered structure and preparation method thereof

A field electron emission, carbon-based nanotechnology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of decreased emission efficiency, poor reliability of a single carbon nanotube, etc., to improve the viscosity coefficient, Expanding application limitations and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

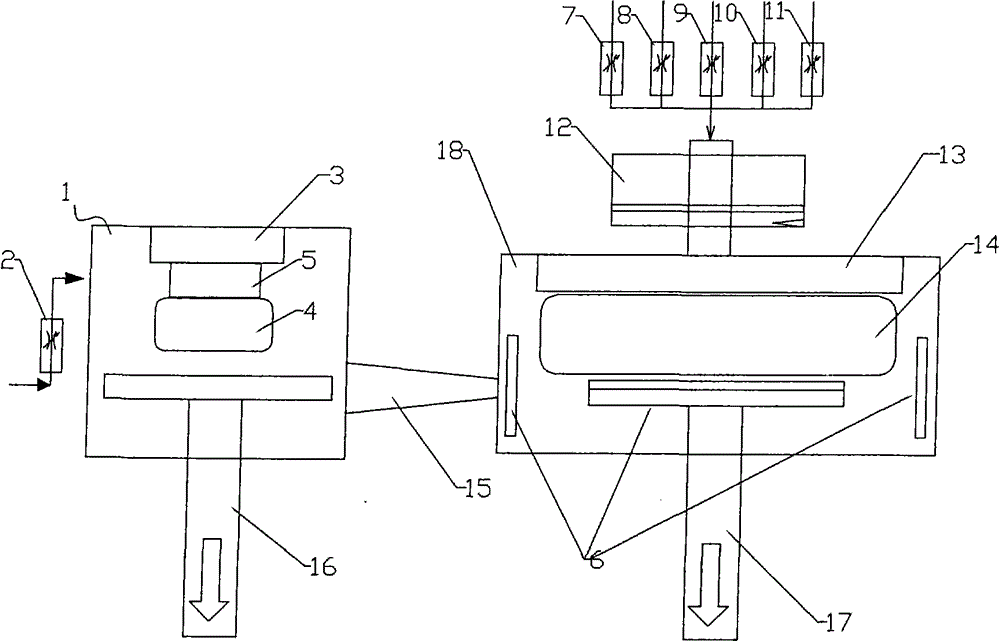

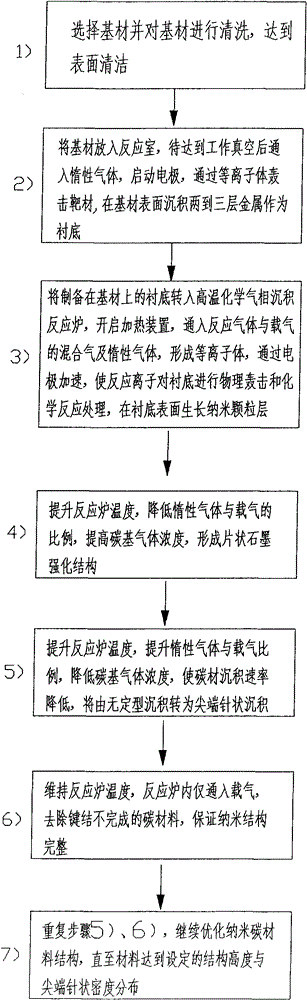

[0052] Such as figure 1 with figure 2 Shown, method of the present invention comprises the following steps:

[0053] 1) Select a metal (such as copper) suitable for the growth of carbon nanomaterials as the substrate, and perform physical and chemical cleaning on the substrate to achieve the surface cleanliness required for deposition;

[0054] 2) Load the cleaned substrate into the magnetron sputtering reaction chamber 1, start the vacuum units 16 and 17, and wait until the vacuum degree reaches 8×10 -4 At Pa, the inert gas is introduced through the flow meter 2 to raise the vacuum degree to 1 Pa and keep it stable, the electrode 3 is started to form a plasma 4, and the target material 5 is bombarded by the plasma to deposit different two to three layers on the substrate. Metal is used as the substrate, and the deposition thickness reaches 100-200 nanometers, and the substrate is nickel;

[0055] 3) After the deposition is completed, wait for the vacuum degree to return t...

Embodiment 2

[0062] 1) Select a semiconductor material (such as silicon) suitable for the growth of carbon nanomaterials as the substrate, and perform physical and chemical cleaning on the substrate to achieve the clean surface state required for deposition;

[0063] 2) Load the cleaned substrate into the magnetron sputtering reaction chamber 1, start the vacuum units 16 and 17, and wait until the vacuum degree reaches 8×10 -4 Pa, pass inert gas through the flowmeter 2, make the vacuum rise to 1Pa and keep it stable, start the electrode 3, form the plasma 4, and bombard the substrate 5 with the plasma, deposit different two to three layers on the substrate The metal is used as the substrate, and the deposition thickness reaches 100-200 nanometers. The substrate is made of chromium-nickel alloy;

[0064] 3) After the deposition is completed, wait for the vacuum degree to return to 10 -3 Pa, the substrate deposited on the base material is sent into the high-temperature chemical vapor deposi...

Embodiment 3

[0071]1) Select a ceramic body suitable for the growth of carbon nanotubes as the substrate, and perform physical and chemical cleaning on the substrate to achieve the clean surface state required for deposition;

[0072] 2) Load the cleaned substrate into the magnetron sputtering reaction chamber 1, start the vacuum units 16 and 17, and wait until the vacuum degree reaches 8×10 -4 Pa, pass inert gas through the flowmeter 2, make the vacuum rise to 1Pa and keep it stable, start the electrode 3, form the plasma 4, and bombard the substrate 5 with the plasma, deposit different two to three layers on the substrate Metal is used as the substrate, and the deposition thickness reaches 100-200 nanometers. The substrate is made of chromium-gold-nickel combination;

[0073] 3) After the deposition is completed, wait for the vacuum degree to return to 10 -3 Pa, the substrate deposited on the base material is sent into the high-temperature chemical vapor deposition reaction chamber 18 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com