Gas supply for gas burners

A gas burner and gas technology, which is applied in the field of nozzle discharge, can solve the problems of non-releasing nozzles, no longer replaceable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

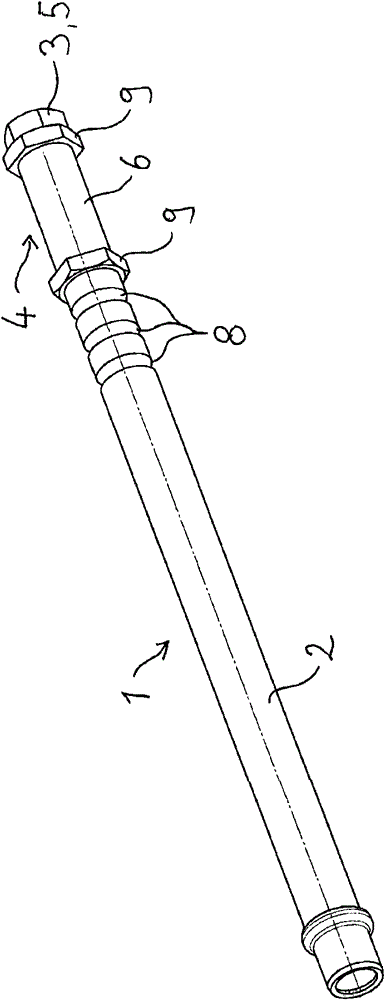

[0032] figure 1 A perspective view of a component 1 according to the invention with a straight nozzle holder 4 into which the nozzle 3 is screwed is shown in detail. The nozzle 3 has a hexagonal outer contour 5 on which a screwdriver can be placed. In order to hold the nozzle holder 4 during the screw-in process, at least one further hexagonal outer contour 9 is provided on the nozzle holder 4 . Reference numeral 8 designates grooves produced by crimping which surround the gas connection pipe 2 . The nozzle holder 4 is connected in a gas-tight manner to the gas connection pipe 2 by deformation (not visible in the figure) caused by crimping inside the gas connection pipe 2 . The area marked with the reference numeral 6 is the fastening section 6 which is used for fastening the component 1 on the gas burner.

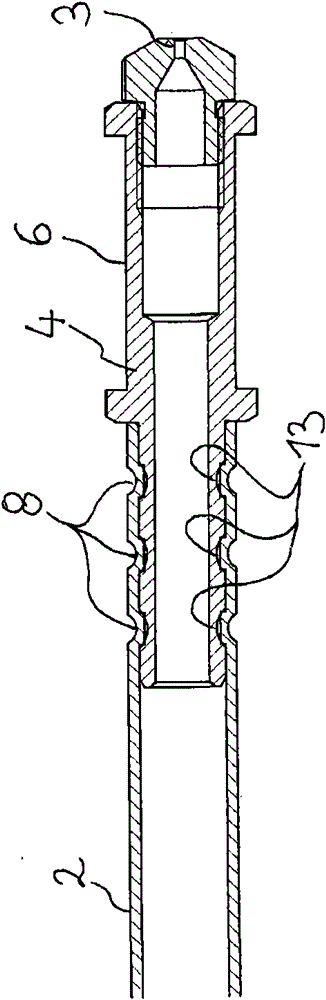

[0033] figure 2 shows that by following the present invention figure 1 The axial section of the component 1 in the region of the nozzle holder 4 , where one can see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com