Multiple nozzle junction of textile machine, textile machine, and method for operating textile machine

A textile machine and multi-nozzle technology, which is applied in the direction of textiles and papermaking, spinning machines, continuous winding spinning machines, etc., can solve the problems of expensive and time-consuming refitting, and achieve the effect of simple refitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

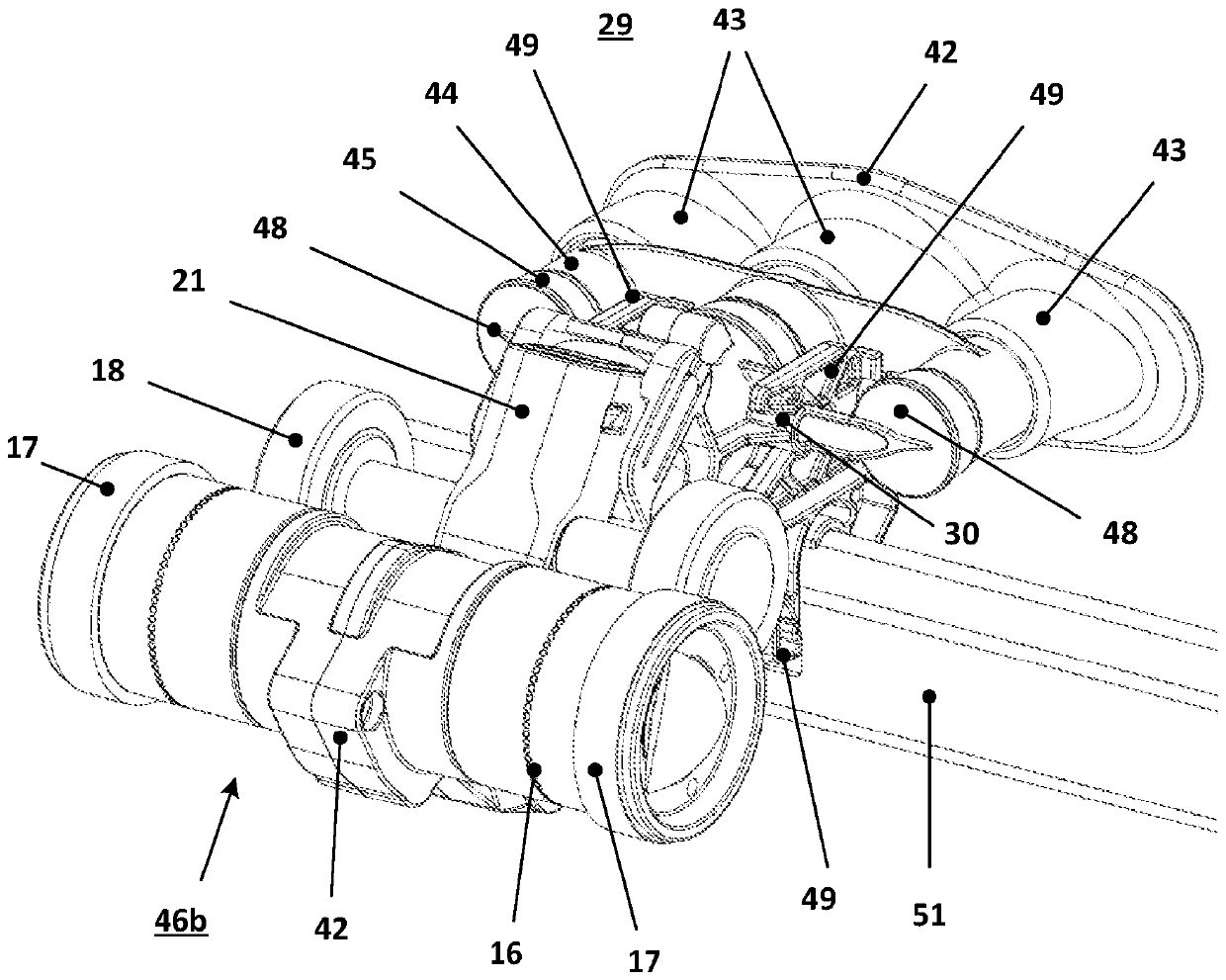

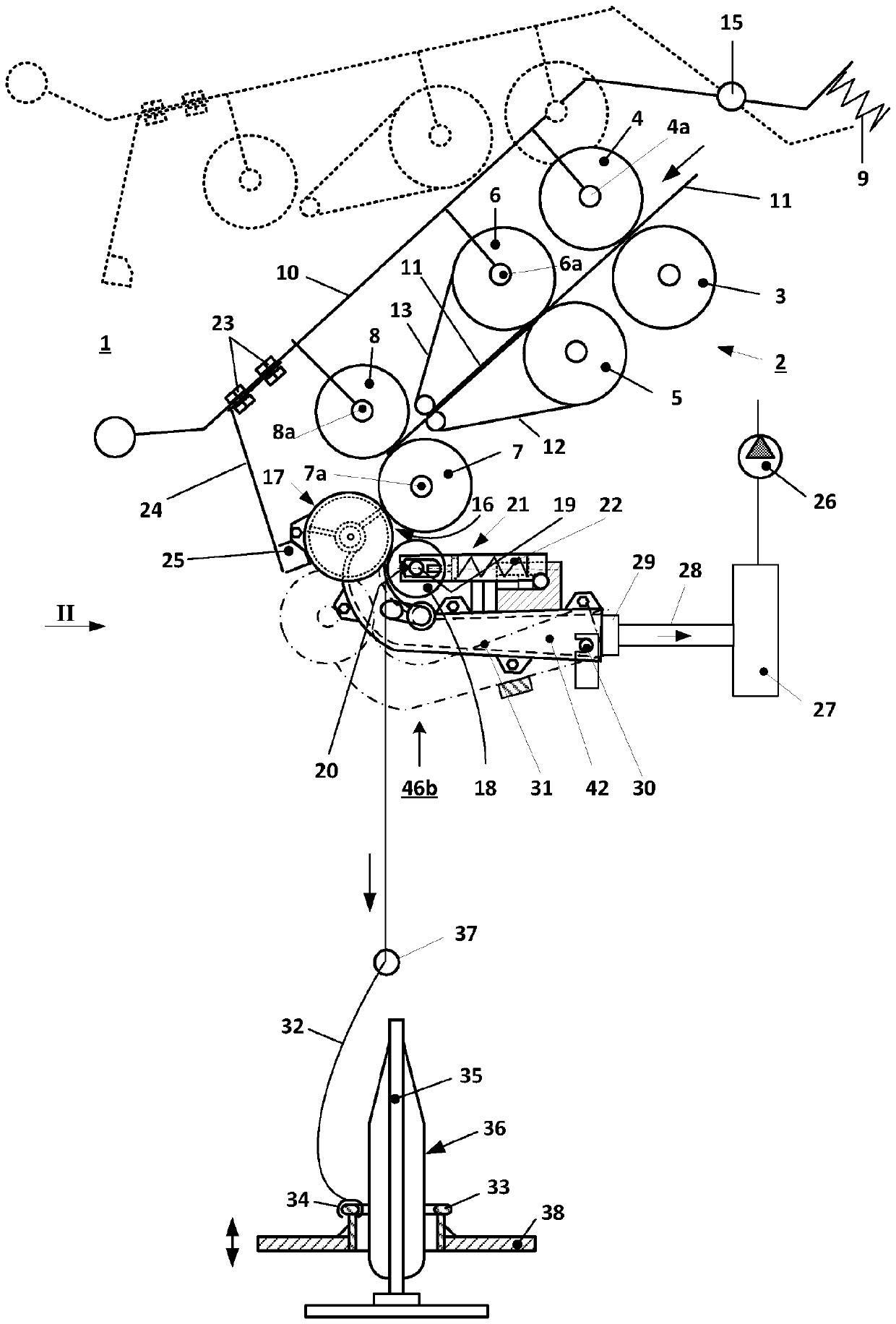

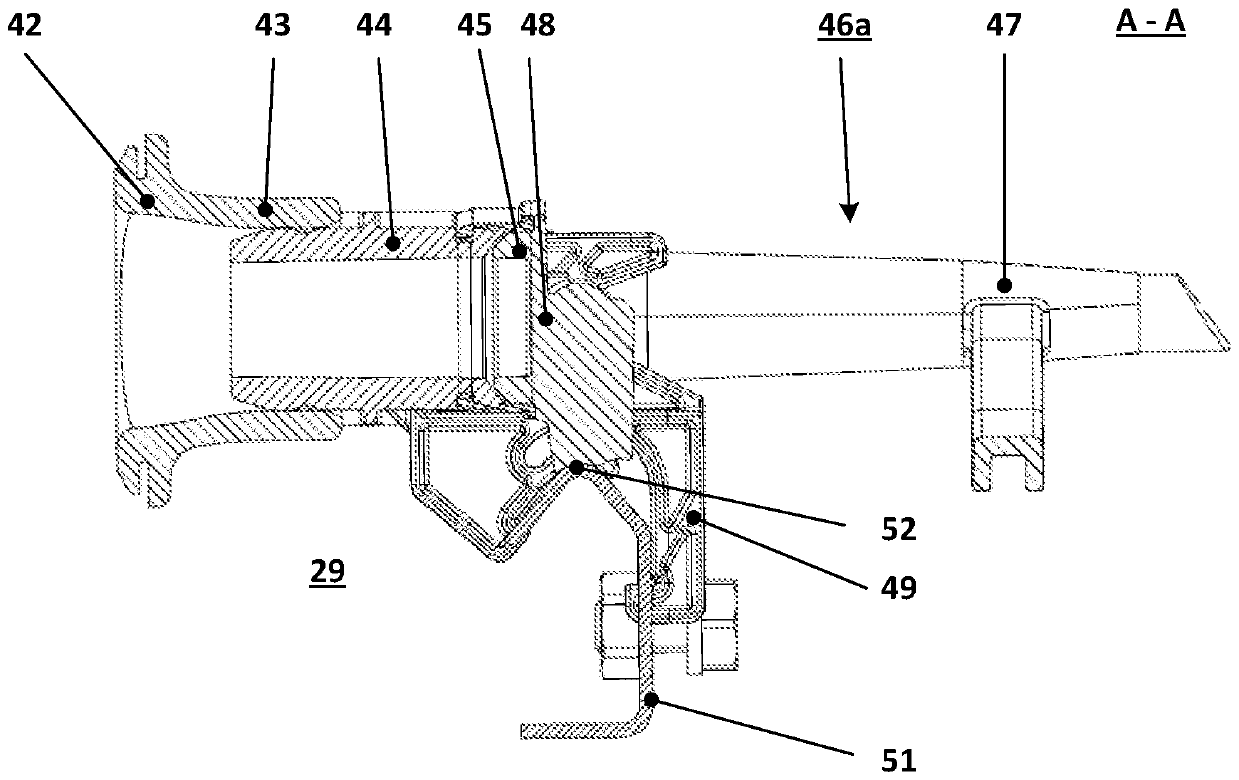

[0036] figure 1Shows a schematic side view of a spinning station 1 of a spinning machine (ring spinning machine) with a drafting mechanism unit 2 provided with a pair of input rollers 3, 4, a pair of intermediate rollers 5, 6 and output roller pair 7,8. Belts 12 , 13 are each guided around intermediate rollers 5 , 6 and are each held in their shown position around cages (not shown in detail). The upper rollers 4 , 6 , 8 of the roller pairs mentioned are designed as pressure rollers, which are mounted rotatably via axes 4 a , 6 a , 8 a on pivotably mounted pressure arms 10 . Two adjacent drafting units 2 (double drafting units) are assigned to one pressing arm 10 . The pressure arm 10 is mounted so as to be pivotable about an axis 15 and is loaded, as schematically shown, by a spring element 9 . The spring element can also be an air hose, for example. The rollers 4 , 6 , 8 are pressed against the lower rollers 3 , 5 and 7 of the roller pair by the schematically indicated sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com