Conditioner for repairing heavy metal polluted soil, and preparation method thereof

A technology of polluted soil and conditioner, which is applied in the field of repairing heavy metal-contaminated soil conditioner and its preparation, can solve the problems of heavy metals entering the soil, secondary pollution, soil heavy metal pollution, etc., to improve permeability, enhance adsorption performance, and benefit fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

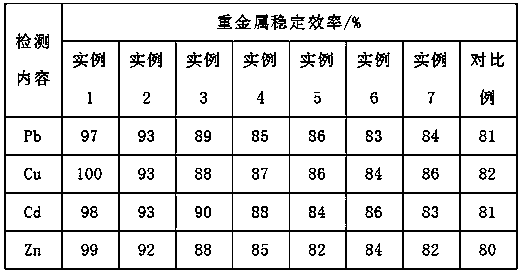

Examples

example 1

[0051] A conditioner for repairing heavy metal polluted soil, comprising the following raw materials in parts by weight: 50 parts of modified cork powder, 20 parts of modified sepiolite, 120 parts of modified gelatin liquid, 3 parts of urease, 3 parts of urea, 3 parts of oyster shell powder, 5 parts casein solution.

[0052] The starch is corn starch.

[0053] The carbomer is carbomer 934.

[0054] A preparation method for repairing heavy metal-contaminated soil conditioner, the specific preparation process of the repair heavy metal-contaminated soil conditioner is:

[0055] (1) In parts by weight, take 50 parts of cork powder, 0.2 parts of wood rotting fungus, and 8 parts of water in turn, put the cork powder, wood rotting fungus, and water in No. 1 ball mill, mix and ball mill for 50 minutes, and then let it stand for 24 hours , filter to obtain No. 1 filter residue, then place No. 1 filter residue in liquid nitrogen and freeze to obtain frozen No. 1 filter residue, then p...

example 2

[0063] A conditioner for repairing heavy metal polluted soil, comprising the following raw materials in parts by weight: 50 parts of cork powder, 20 parts of modified sepiolite, 120 parts of modified gelatin solution, 3 parts of urease, 3 parts of urea, 3 parts of oyster shells powder, 5 parts casein solution.

[0064] The starch is corn starch.

[0065] The carbomer is carbomer 934.

[0066] A preparation method for repairing heavy metal-contaminated soil conditioner, the specific preparation process of the repair heavy metal-contaminated soil conditioner is:

[0067] (1) In terms of parts by weight, take 20 parts of sepiolite, 30 parts of hydrochloric acid, and 50 parts of water in turn, put the sepiolite in a muffle furnace, and roast it for 3 hours at a temperature of 750°C to obtain Sepiolite, then the roasted sepiolite is placed in No. 5 ball mill for ball milling, and a 160-mesh sieve is obtained to obtain pretreated sepiolite. The pretreated sepiolite and the mass fr...

example 3

[0072] A conditioner for repairing heavy metal polluted soil, comprising the following raw materials in parts by weight: 50 parts of modified cork powder, 20 parts of modified sepiolite, 120 parts of gelatin solution, 3 parts of urease, 3 parts of urea, 3 parts of oyster shells powder, 5 parts casein solution.

[0073] The starch is corn starch.

[0074] A preparation method for repairing heavy metal-contaminated soil conditioner, the specific preparation process of the repair heavy metal-contaminated soil conditioner is:

[0075] (1) In parts by weight, take 50 parts of cork powder, 0.2 parts of wood rotting fungus, and 8 parts of water in turn, put the cork powder, wood rotting fungus, and water in No. 1 ball mill, mix and ball mill for 50 minutes, and then let it stand for 24 hours , filter to obtain No. 1 filter residue, then place No. 1 filter residue in liquid nitrogen and freeze to obtain frozen No. 1 filter residue, then put the frozen No. 1 filter residue in No. 2 ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com