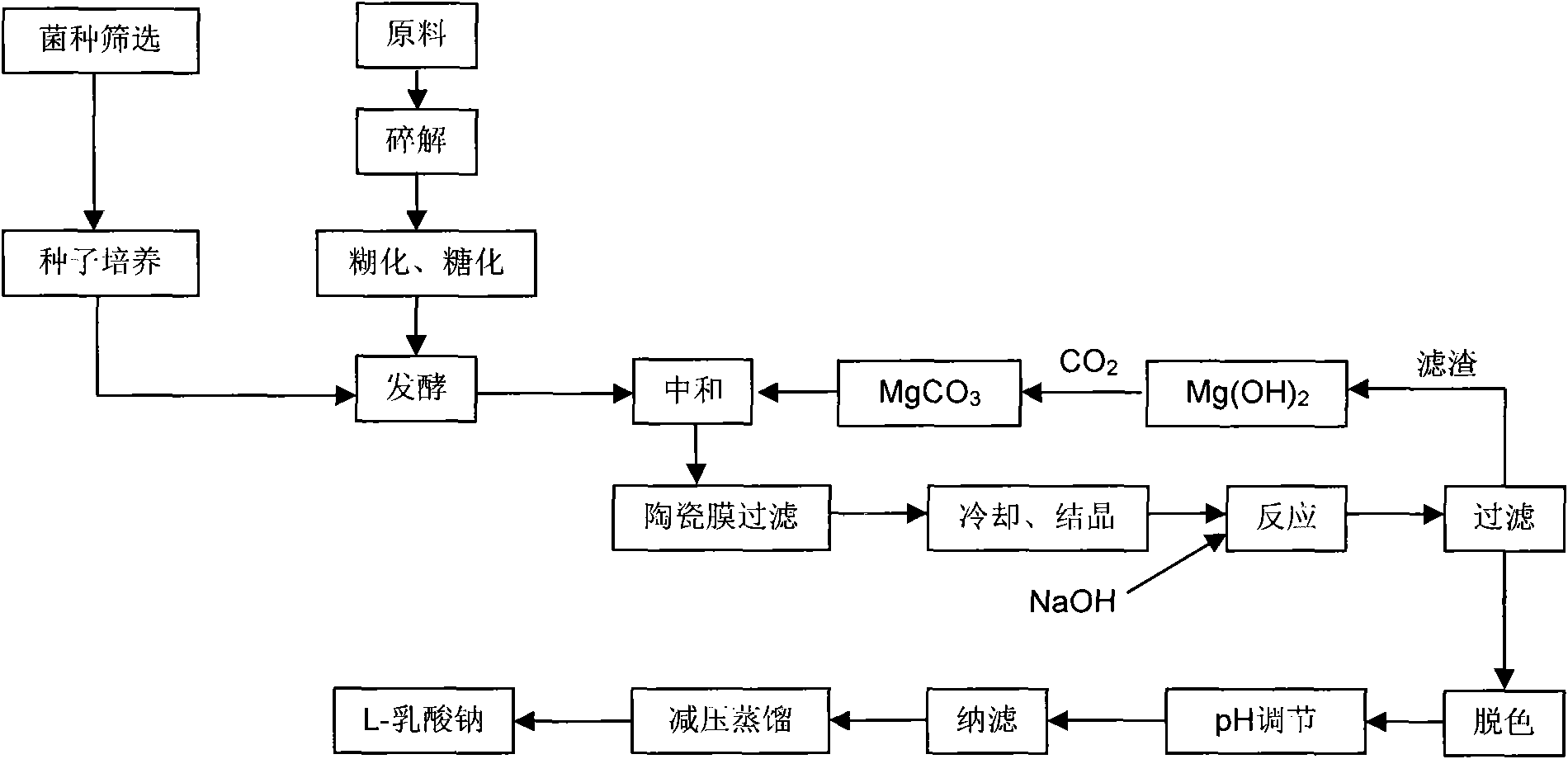

Method for preparing L-sodium lactate with high optical purity

A technology of optical purity and sodium lactate, which is applied in the biological field, can solve the problems such as the lack of detailed introduction of lactate separation and purification steps, and achieve the effects of reducing solid by-products, good economy, and high saccharification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: Breeding of thermophilic L-lactic acid-producing Lactobacillus coagulans

[0081] (1) Medium composition

[0082] Seed medium (g / L): glucose 20, yeast extract 10, peptone 10, anhydrous MgSO 4 0.25, light MgCO 3 7.5-8.2, pH 5.0-6.0.

[0083] Fermentation medium (g / L): glucose 170-190, yeast extract 1-5, peptone 0.5-5, anhydrous MgSO 4 0.25~0.5, light MgCO 3 65-75, pH 5.0-6.0.

[0084] (2) Genetic breeding

[0085] The starting strain CICIM B1820 (Tian Kangmingshi Guiyang Wang Zhengxiang. Food Research and Development 2009, 30(8): 1-5), through polymerase chain reaction, artificially synthesized oligonucleotides (sequence No.1 and No. 2) as a primer, clone the gene encoding L-lactate dehydrogenase from the chromosomal DNA of the bacterial strain CICIM B1820, insert it into a cloning vector such as pET-28a, obtain the recombinant plasmid pET-ldhL, and transform it through protoplasts Method (Mo Jingyan, Chen Xianzhong, Wang Zhengxiang. Biotechnology 20...

Embodiment 2

[0087] Embodiment 2 fermentation produces L-sodium lactate

[0088] The recombinant thermophilic Bacillus coagulans obtained by screening in Example 1 was used for fermenting and producing seeds after static culture at 55-65° C. for 48 hours.

[0089] (1) Level 1 5L self-controlled glass tank culture

[0090] Cook sweet potato powder at 115°C for 20 minutes to sterilize, add 0.1% medium-temperature α-amylase (Jiangyin Baishenglong Biological Engineering Co., Ltd.) to liquefy at 80°C for 60 minutes, and transport 4 L of fully liquefied feed liquid to the fermenter , cooled to 65°C, adding 0.1%-0.3% glucoamylase and nutrients required for the growth of recombinant thermophilic bacteria, under anaerobic conditions at 50-56°C, pH value to 5.0-6.5, more preferably 5.0-5.5 Inject 5%-7% recombinant thermophile RY-18 under the conditions, and ferment for 32 hours. The content of lactic acid was analyzed to be 172g / L, the optical purity of L-lactic acid was 99.6%, and the conversion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com