Heavy metal waste slag treatment method and sulfur building material prepared thereby

A treatment method and technology for heavy metals, applied in the field of environmental engineering, to reduce environmental damage, facilitate harmless treatment, and increase utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

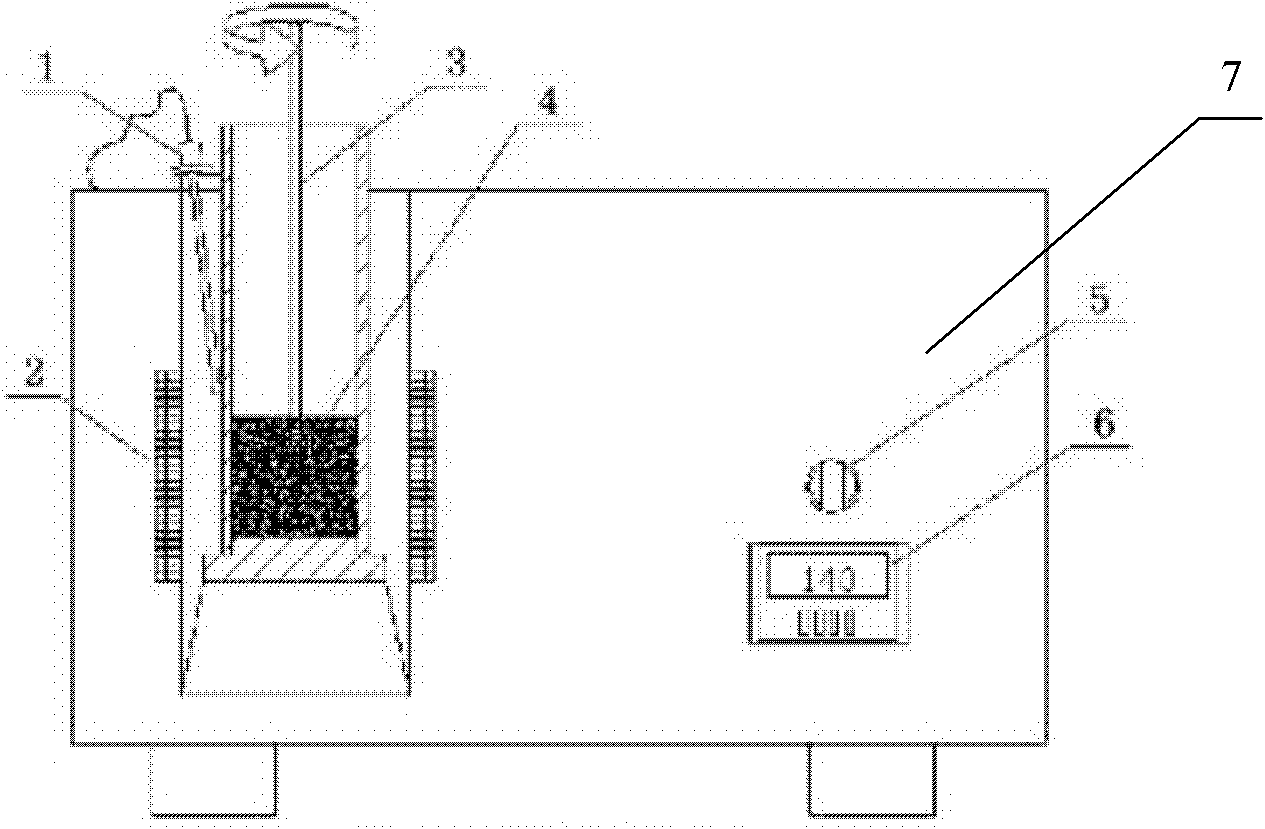

Method used

Image

Examples

Embodiment 1

[0026] Step 1. Retrieve the slag of the polluted acid system produced by a smelter, including heavy metal waste slag and gypsum slag. The specific operation is as follows: the flue gas generated in the roasting section of the lead-zinc smelter is sent to the acid production section through pipelines, and the flue gas Part of the soot that has not been cleaned in the dust collection stage will form dirty acid after washing with water, and the dirty acid will form heavy metal waste residue after sulfide precipitation, and the supernatant will be neutralized and precipitated to obtain gypsum slag, the main component of which is CaSO 4 2H 2 O.

[0027] The leaching toxicity test of heavy metal waste slag and gypsum slag was done, and the results are shown in Table 1.

[0028] Table 1 The leaching toxicity of heavy metal waste slag and gypsum slag

[0029] Unit: mg / L (-- means not detected)

[0030]

[0031] It can be seen from Table 1 that most of the heavy metals in the hea...

Embodiment 2

[0041] Step 1, according to the method of step 2 in Example 1, soak 100 g of heavy metal waste slag with 400 ml of 1mol / L sodium sulfide solution, and stir for 24 hours by mechanical stirring, filter out the slag sample, and place the gypsum slag in an oven to dry at the same time. Grind finely and pass through a 100-mesh sieve.

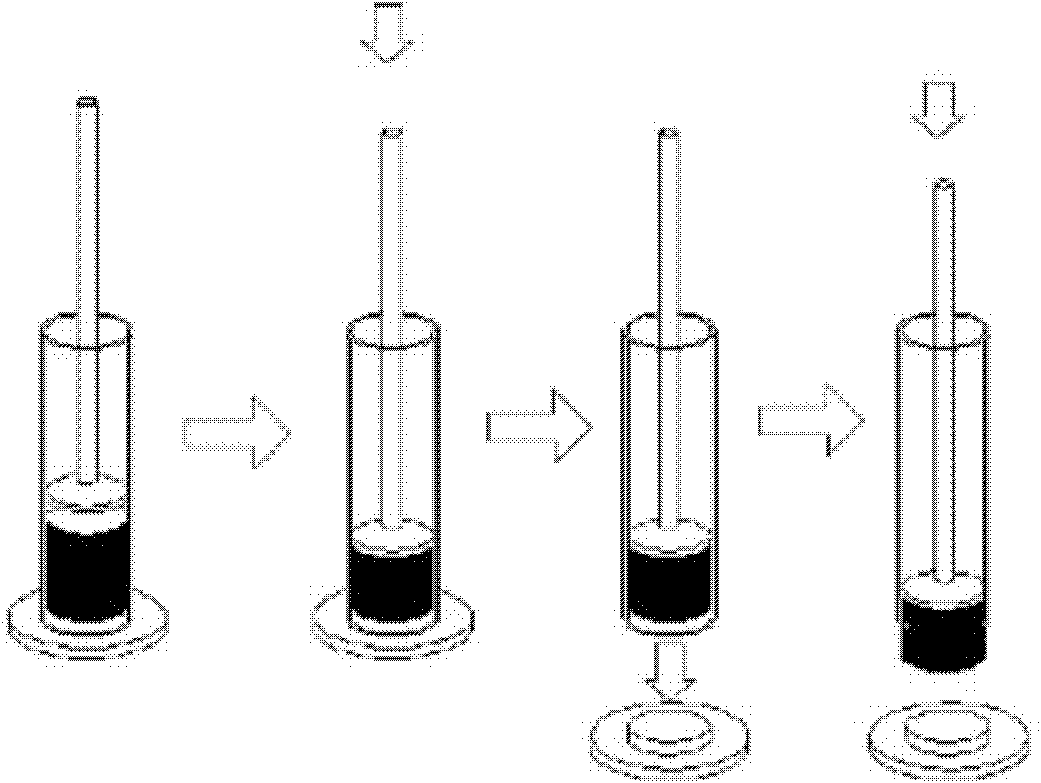

[0042] Step 2: Weigh 27.5g of heavy metal waste slag, 12.5g of sulfur, and 10g of gypsum slag after the pre-sulfurization treatment, mix them evenly, place the mixture in a mold, and heat it in a heating furnace within the range of 140-150°C, constantly stirring Rod stirring, during the heating process, the sulfur gradually melts and the slag sample forms a sticky shape. After 20-40 minutes, the mold is taken out of the heating furnace, compacted with a compacting rod, cooled, and demoulded to obtain sulfur building materials.

[0043] Step 3: Do a compression test on the sulfur building material, and the strength can reach 21.9Mpa. The building mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com