Self-lubricating metallic material

A metal material, self-lubricating technology, applied in metal material coating process, metal layered products, ion implantation plating, etc., can solve the problems of easy wear, low bonding force between lubricating layer and substrate, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Using stainless steel as the base material, ultrasonic cleaning is performed first, and then radio frequency sputtering in physical vapor deposition technology is used to deposit WS 2 The solid lubricating material is deposited on the metal surface with a thickness of 0.5 μm. The friction coefficient of the surface of the obtained self-lubricating stainless steel material is 0.0355, and has excellent wear-reducing and wear-resisting properties. The wear rate before and after coating decreased from 2.486×10-5g / m to 0.399×10-5g / m., and the friction coefficient decreased from 0.29 to 0.0355.

Embodiment 2

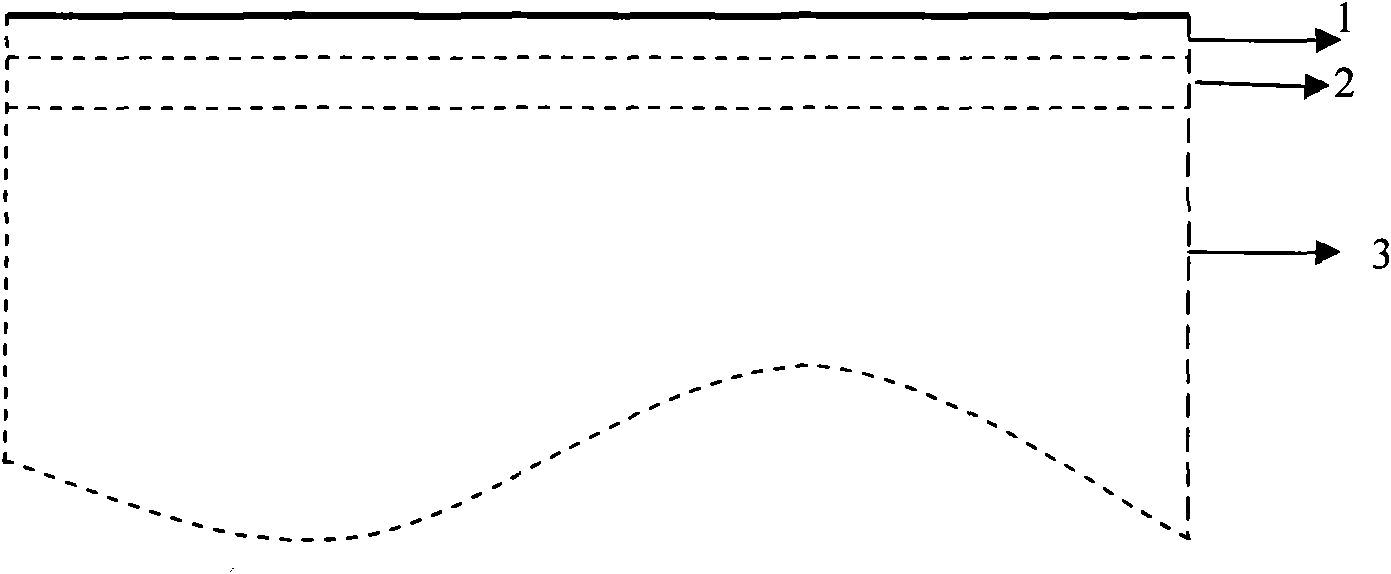

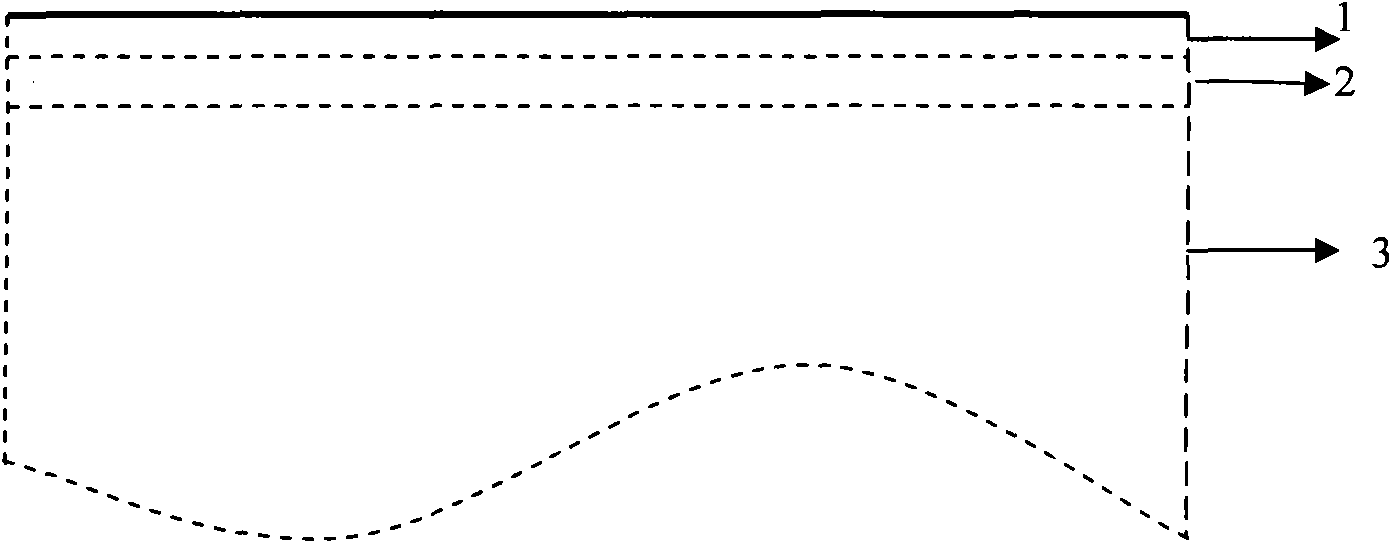

[0020] Using die steel as the base material 3, ultrasonic cleaning is first performed, and then the MEVVA source ion implantation technology (metal vapor vacuum arc ion source technology) is used to bond TiN to the surface of the metal substrate to form a base layer 2 of lubricating film with high hardness, with a thickness of 0.005 μm. Then on the TiN coating, WS is covered by RF sputtering in physical vapor deposition technology. 2 Coating 1 with a thickness of 0.8 μm. The obtained self-lubricating die steel has high TiN hardness and good anti-corrosion effect, and WS 2 Comprehensive functions of lubrication, high temperature resistance and low coefficient of friction. And because the processing thickness of the double-layer lubricating cladding layer is micron level, it can meet the matching tolerance between the mold and the processed parts, reduce the processing cost, and is suitable for the processing and production of various wear-resistant molds.

Embodiment 3

[0022] Using copper as the base material, first perform ultrasonic cleaning, and then use MEVVA source ion implantation technology (metal vapor vacuum arc ion source technology) to bond DLC to the surface of the metal substrate to form a high-hardness lubricating film base layer 2 with a thickness of 0.005 μm . Then on the DLC coating, WS is covered by radio frequency sputtering in physical vapor deposition technology. 2 Coating 1 with a thickness of 0.8 μm. The obtained self-lubricating die steel has high TiN hardness and good anti-corrosion effect, and WS 2 Comprehensive function of lubricating low coefficient of friction. It is suitable for the processing and production of various wear-resistant moving parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com