Super-amphiphobic corrosion resistant coating for rain gauge and preparation method thereof

A corrosion-resistant coating, super-amphiphobic technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of water funnels being easily corroded, easily stained with impurities, and affecting the service life of rain gauges, etc., to achieve excellent Hydrophobic and oleophobic properties and anti-fouling properties, good high temperature resistance, improved service life and the effect of measurement precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

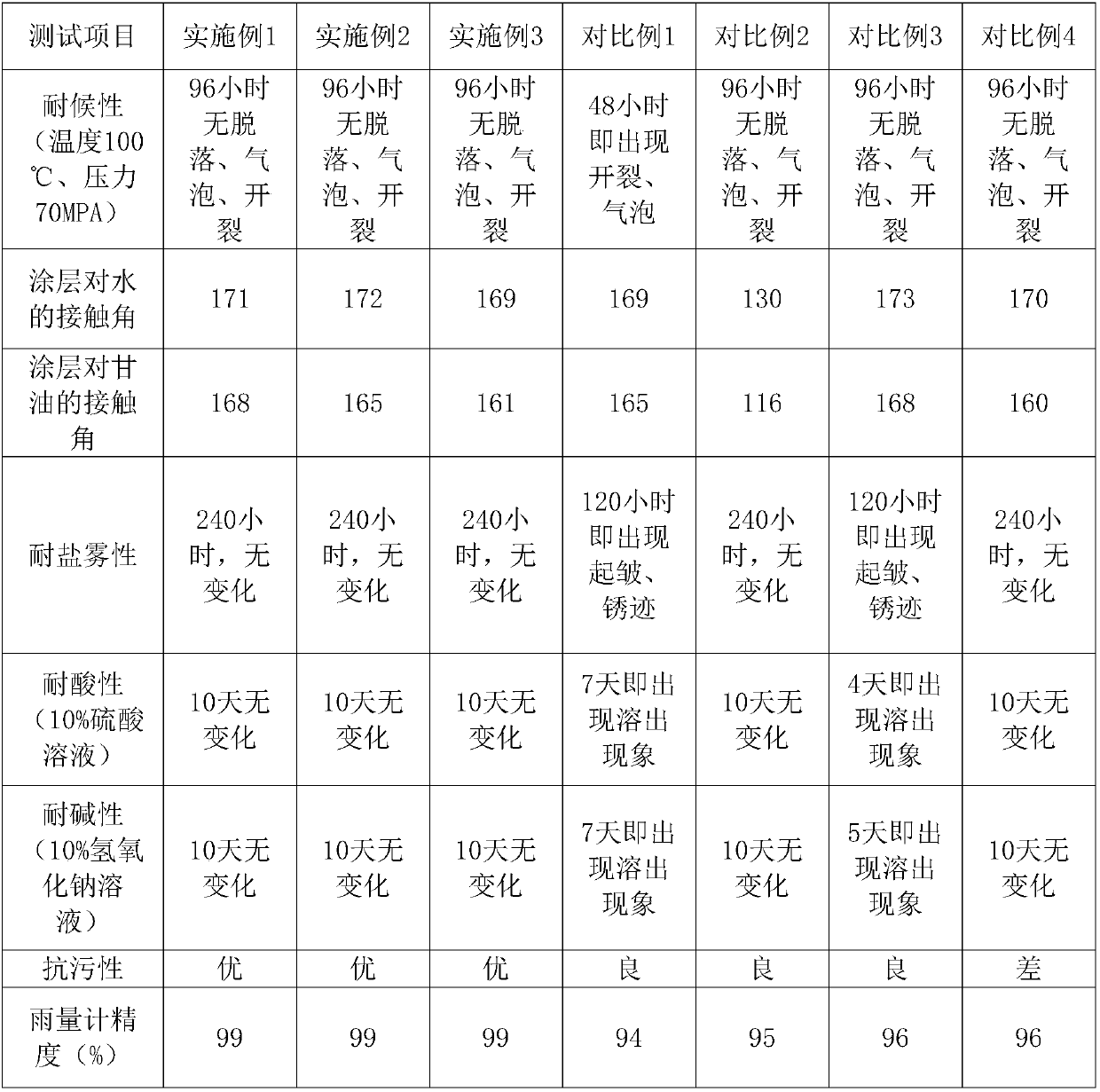

Examples

preparation example Construction

[0045] Specifically, the preparation method of the superamphiphobic corrosion-resistant coating for rain gauges includes: by weight, 40-60 parts of silicone epoxy resin, 10-20 parts of polytetrafluoroethylene, polyether ether 10-20 parts of ketone, 20-25 parts of polydopamine, 20-25 parts of nano-polyaniline modified oxyferric chloride, 5-10 parts of aluminum tripolyphosphate, 5-10 parts of talcum powder, 5-10 parts of nano-silver particles 1 to 3 parts of silane coupling agent, 1 to 2 parts of wetting agent, 0.5 to 2 parts of defoamer, 0.5 to 2 parts of dispersant, and 30 to 50 parts of n-butanol to obtain the first component and then uniformly mix the first component with 5-10 parts of curing agent, so as to obtain the super amphiphobic corrosion-resistant coating for rain gauge. In practical applications, the nano-polyaniline modified oxyferric chloride is preferably prepared by the following preparation method, which may specifically include the following steps:

[0046] ...

Embodiment 1

[0056] A superamphiphobic corrosion-resistant coating for rain gauges, the preparation method comprising: by weight, 60 parts of silicone epoxy resin, 20 parts of polytetrafluoroethylene, 20 parts of polyether ether ketone, polydopamine 25 parts, 25 parts of nano-polyaniline modified oxyferric chloride, 10 parts of aluminum tripolyphosphate, 10 parts of talcum powder, 10 parts of nano-silver particles, 3 parts of silane coupling agent, 2 parts of wetting agent, defoamer 2 parts, 2 parts of dispersant, and 50 parts of n-butanol are mixed together to obtain the first component; and then the first component is uniformly mixed with 10 parts of curing agent, thereby making a super amphiphobic corrosion-resistant coating .

Embodiment 2

[0058] A superamphiphobic corrosion-resistant coating for rain gauges, the preparation method comprising: by weight, 40 parts of silicone epoxy resin, 10 parts of polytetrafluoroethylene, 10 parts of polyether ether ketone, polydopamine 20 parts, 20 parts of nano-polyaniline modified oxyferric chloride, 5 parts of aluminum tripolyphosphate, 5 parts of talcum powder, 5 parts of nano-silver particles, 10 parts of silane coupling agent, 1 part of wetting agent, defoamer 0.5 parts, 0.5 parts of dispersant, and 30 parts of n-butanol are mixed together to obtain the first component; then the first component is uniformly mixed with 5 parts of curing agent to obtain a super amphiphobic corrosion-resistant coating .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com