Manganese-based low-temperature denitration catalyst and preparation method thereof

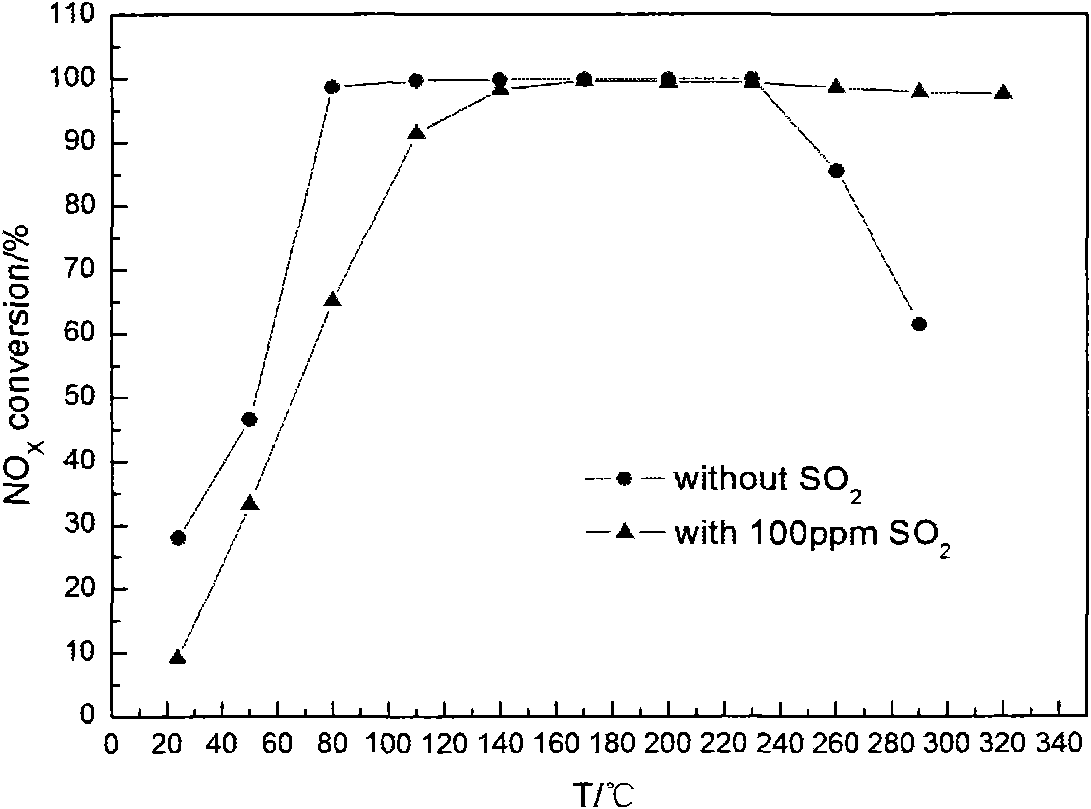

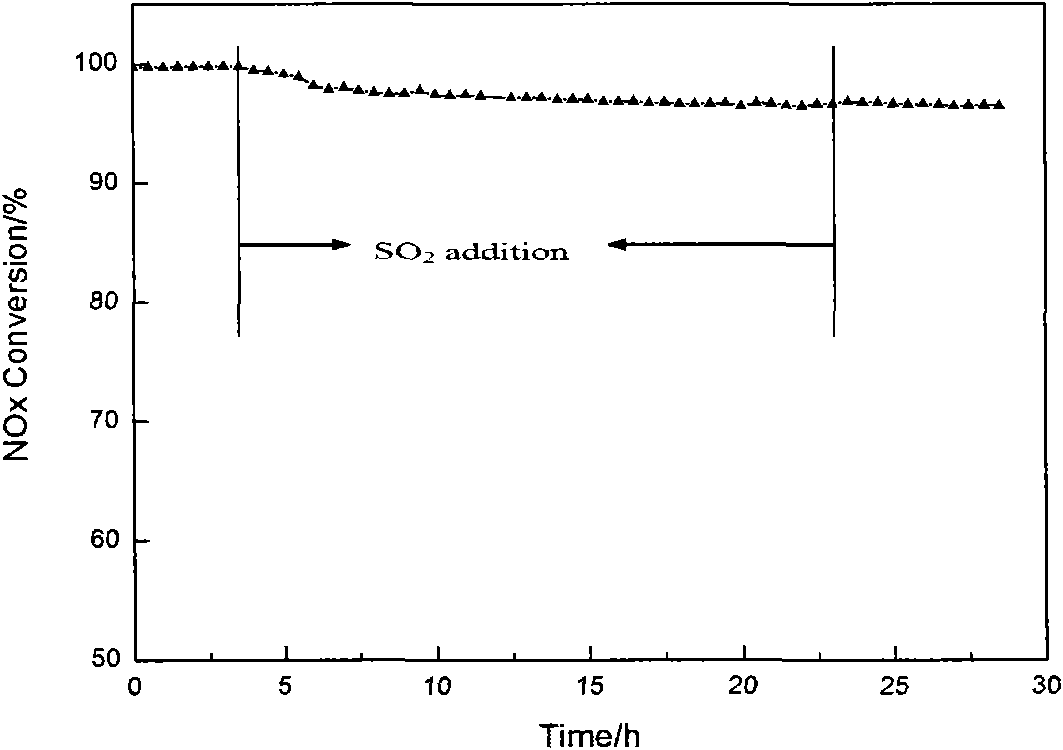

A low-temperature denitration and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of human and environmental pollution, catalyst poisoning, high fly ash content, and achieve good sulfur resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

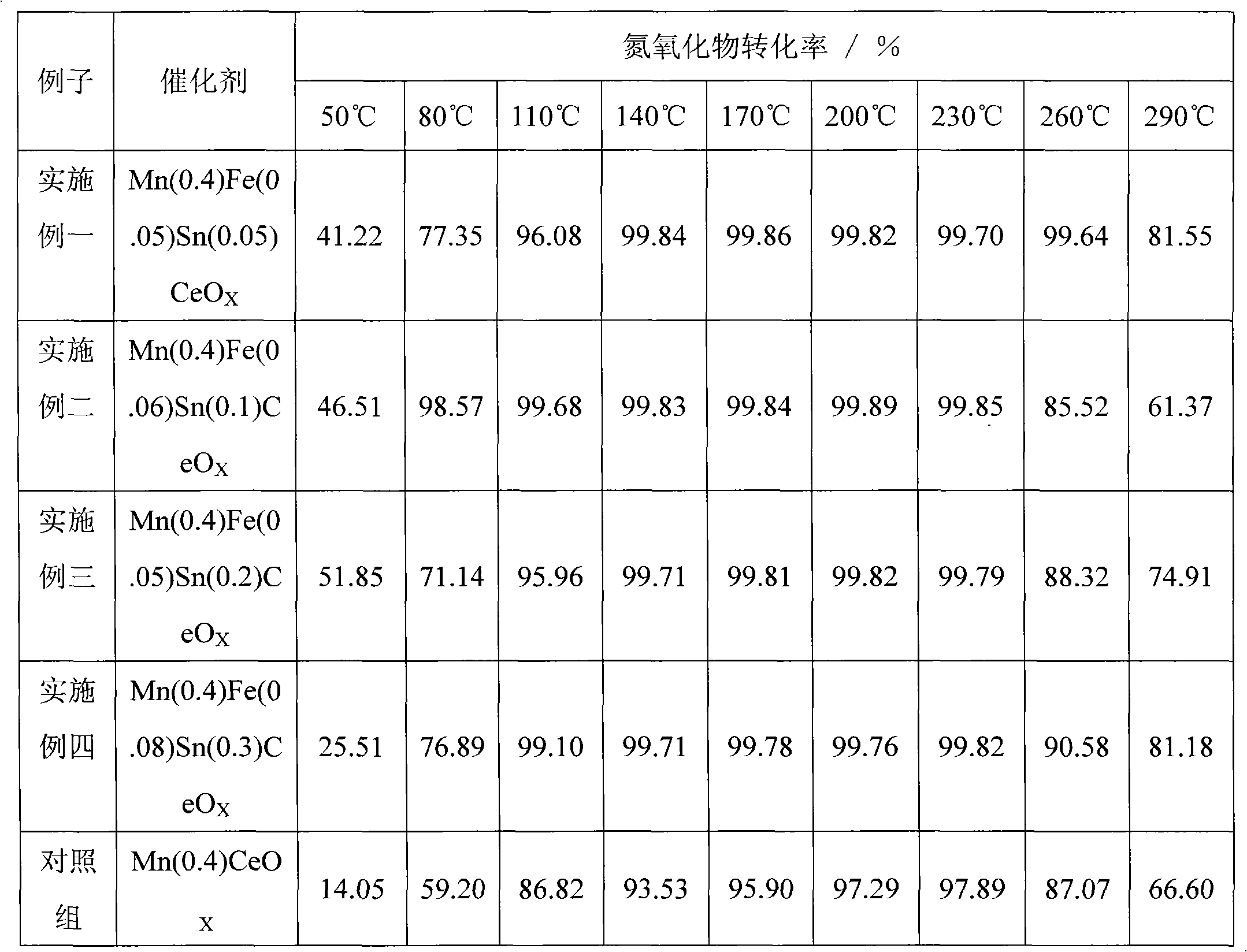

Embodiment 1

[0015] A manganese-based low-temperature denitrification catalyst, the raw material components of which are: manganese nitrate with a content of 40% of the molar percentage of the catalyst, iron nitrate with a content of 5% of the molar percentage of the catalyst, and a content of 5% of the molar percentage of the catalyst 5% crystalline tin tetrachloride, the balance being cerium nitrate.

[0016] A method for preparing a manganese-based low-temperature denitration catalyst, comprising the following steps:

[0017] Step 1. Dissolve manganese nitrate, ferric nitrate, crystalline tin tetrachloride and cerium nitrate in 100 times molar water at room temperature, and stir to form a transparent solution, wherein the content of manganese nitrate is 40% of the molar percentage of the catalyst, and the content of ferric nitrate Ferric nitrate which is 5% of the molar percentage of the catalyst, the content of crystalline tin tetrachloride is 5% of the molar percentage of the catalyst...

Embodiment 2

[0024] A manganese-based low-temperature denitrification catalyst, the raw material components of which are: manganese nitrate with a content of 40% of the molar percentage of the catalyst, iron nitrate with a content of 6% of the molar percentage of the catalyst, and a content of 6% of the molar percentage of the catalyst 10% crystalline tin tetrachloride, the balance being cerium nitrate.

[0025] A method for preparing a manganese-based low-temperature denitration catalyst, comprising the following steps:

[0026] Step 1. Dissolve manganese nitrate, ferric nitrate, crystalline tin tetrachloride and cerium nitrate in water of 110 times molar weight at room temperature, and stir to form a transparent solution, wherein the content of manganese nitrate is 40% of the molar percentage of the catalyst, and the content of ferric nitrate Ferric nitrate which is 6% of the molar percentage of the catalyst, the content of crystalline tin tetrachloride is 10% of the molar percentage of ...

Embodiment 3

[0038] A manganese-based low-temperature denitrification catalyst, the raw material components of which are: manganese nitrate with a content of 40% of the molar percentage of the catalyst, iron nitrate with a content of 5% of the molar percentage of the catalyst, and a content of 5% of the molar percentage of the catalyst 20% crystalline tin tetrachloride, the balance being cerium nitrate.

[0039] A method for preparing a manganese-based low-temperature denitration catalyst, comprising the following steps:

[0040] Step 1. Dissolve manganese nitrate, ferric nitrate, crystalline tin tetrachloride and cerium nitrate in water of 115 times the molar weight at room temperature, and stir to form a transparent solution, wherein the content of manganese nitrate is 40% of the molar percentage of the catalyst, and the content of ferric nitrate Ferric nitrate which is 5% of the molar percentage of the catalyst, the content of crystalline tin tetrachloride is 20% of the molar percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com