Multi-layer porous scaffold and preparation method thereof

A porous stent and the technology on the stent are applied to the multi-layer porous stent and the field of preparation thereof, which can solve the problems of lack of communication of the stent, and achieve the effects of avoiding the residue of harmful substances and avoiding weakened separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

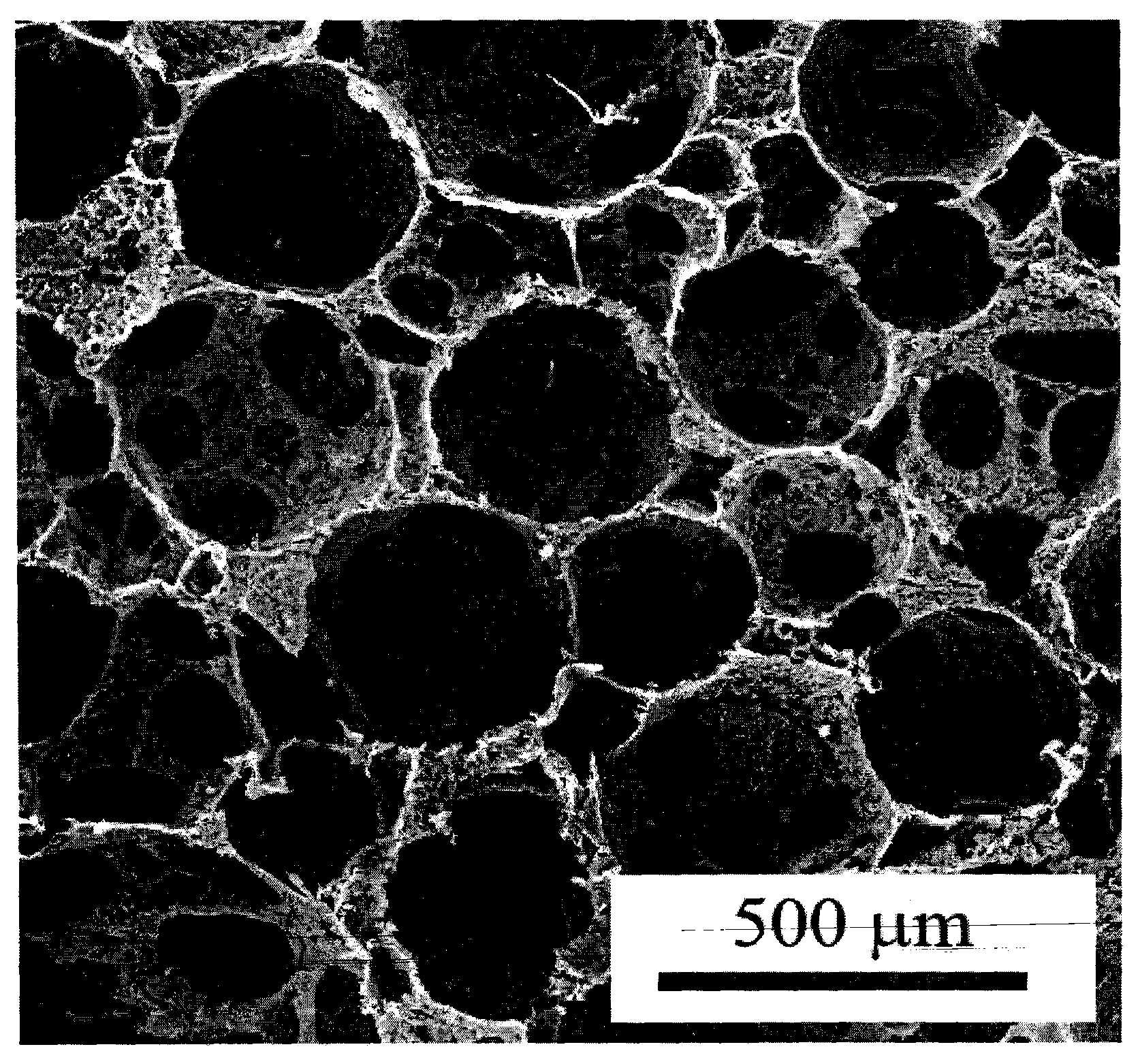

[0044] Firstly, salt particles and spherical paraffin porogen particles are prepared. The salt particles are crushed mechanically and then sieved through a standard sieve to collect particles in different particle size ranges. Paraffin wax microspheres use 1.0g gelatin and 20.0g paraffin wax, add them into 400ml deionized water, heat to 80°C under 400rpm mechanical stirring, then add 300ml ice water to quench to solidify the wax balls. Filter, wash twice with deionized water, and sieve with standard drying after drying to collect particles in different particle size ranges.

[0045] Next prepare the adhesive. Dissolve 0.5g of PLGA85 / 15 with a molecular weight of 300,000 in 8.0ml of dichloromethane, add 9.5g of sodium chloride salt particles with a particle size of 350-455μm into the polymer solution, mix and stir evenly.

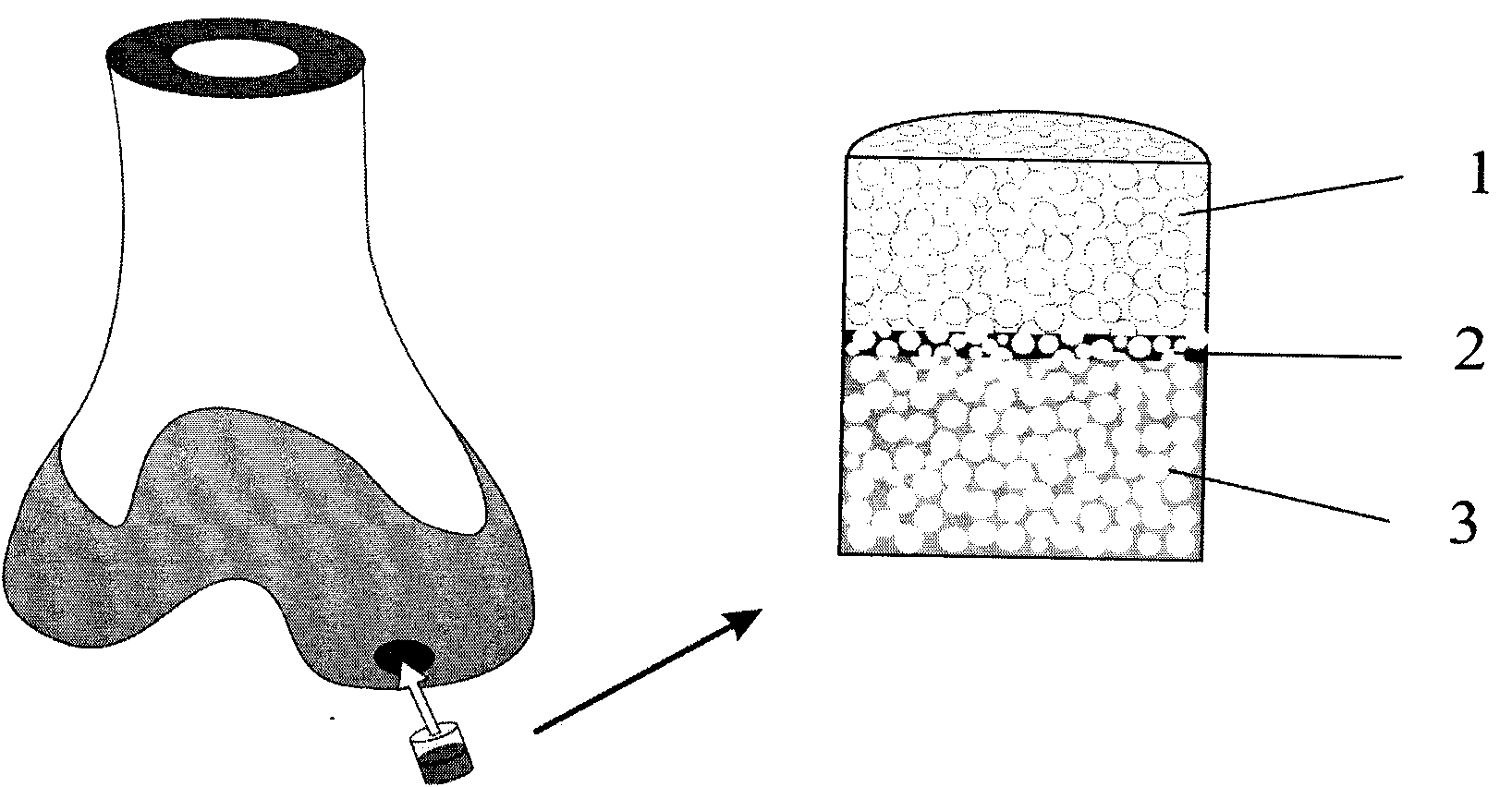

[0046] Take two columnar PLGA85 / 15 porous scaffolds (height 5mm, diameter 10mm, porosity 90%, pore diameter 350-455μm) made of paraffin microspheres, and ...

Embodiment 2

[0048] The support adopts two columnar PLGA85 / 15 porous supports made of paraffin microspheres with different porosities, one of which has a porosity of 95%, and the other has a porosity of 85% (height 5mm, diameter 10mm, pore size 350-455μm), and the remaining conditions and implementation Same as Example 1, a double-layer porous scaffold composed of materials with different porosity was prepared.

Embodiment 3

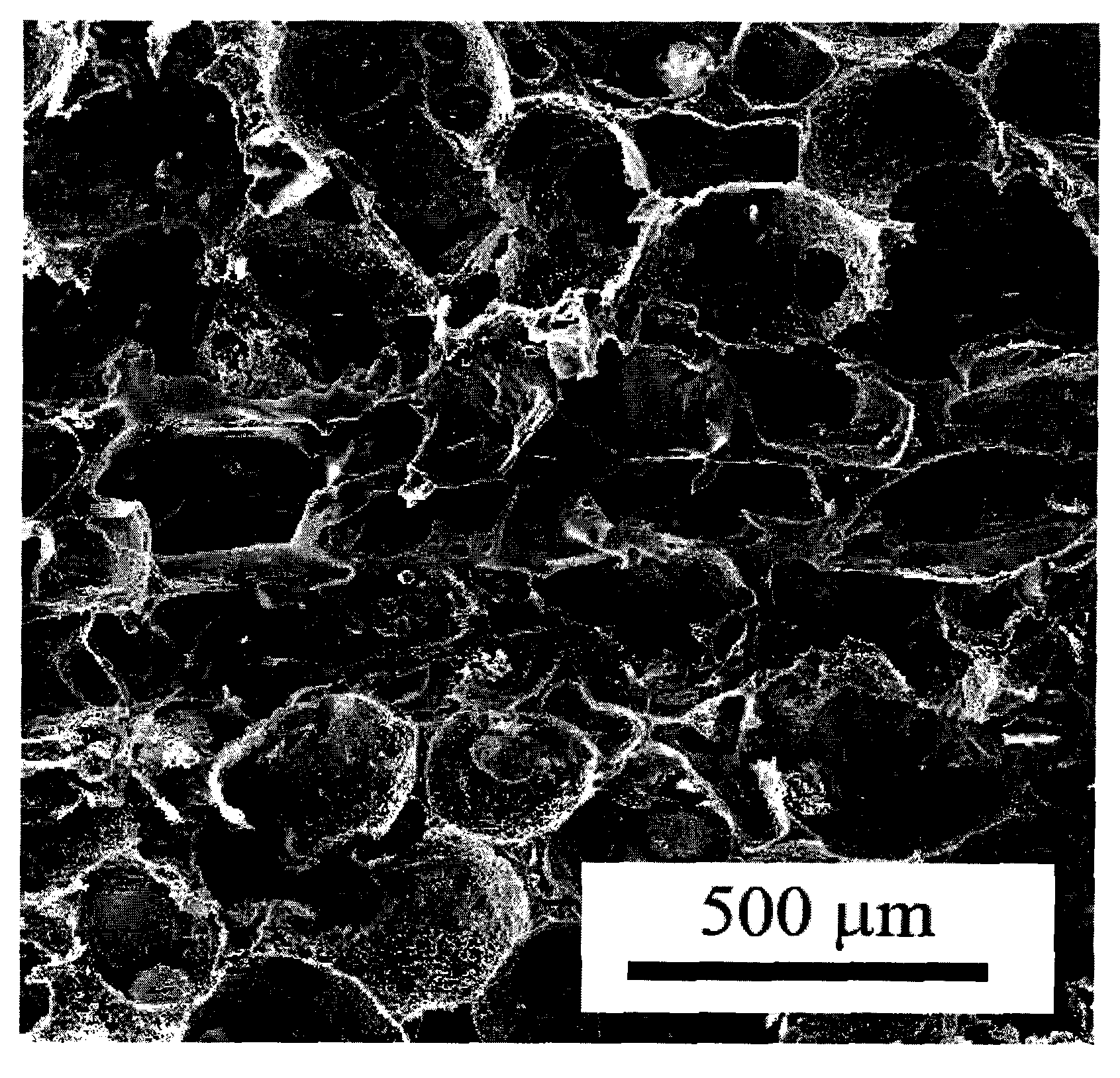

[0050] The scaffold adopts two columnar PLGA85 / 15 porous scaffolds (height 5mm, diameter 10mm, porosity 90%, pore diameter 350-455μm) obtained by different pore-forming processes, one of which is made of sodium chloride salt particles, and the other is made of paraffin microspheres. Pore-causing, other conditions are the same as in Example 1, and a composite porous scaffold with one layer of regular spherical pores and another layer of irregular pores is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com