Electrolyte used for treating aluminium foil in aluminium electrolytic capacitor

A technology for aluminum electrolytic capacitors and electrolytes, applied in the field of electrolytes, can solve problems such as large surface tension, affecting the leakage current and reliability of aluminum electrolytic capacitors, and affecting the properties of oxide film media, so as to improve leakage current and reliability, and be suitable for Effect of large-scale technical improvement and reduction of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

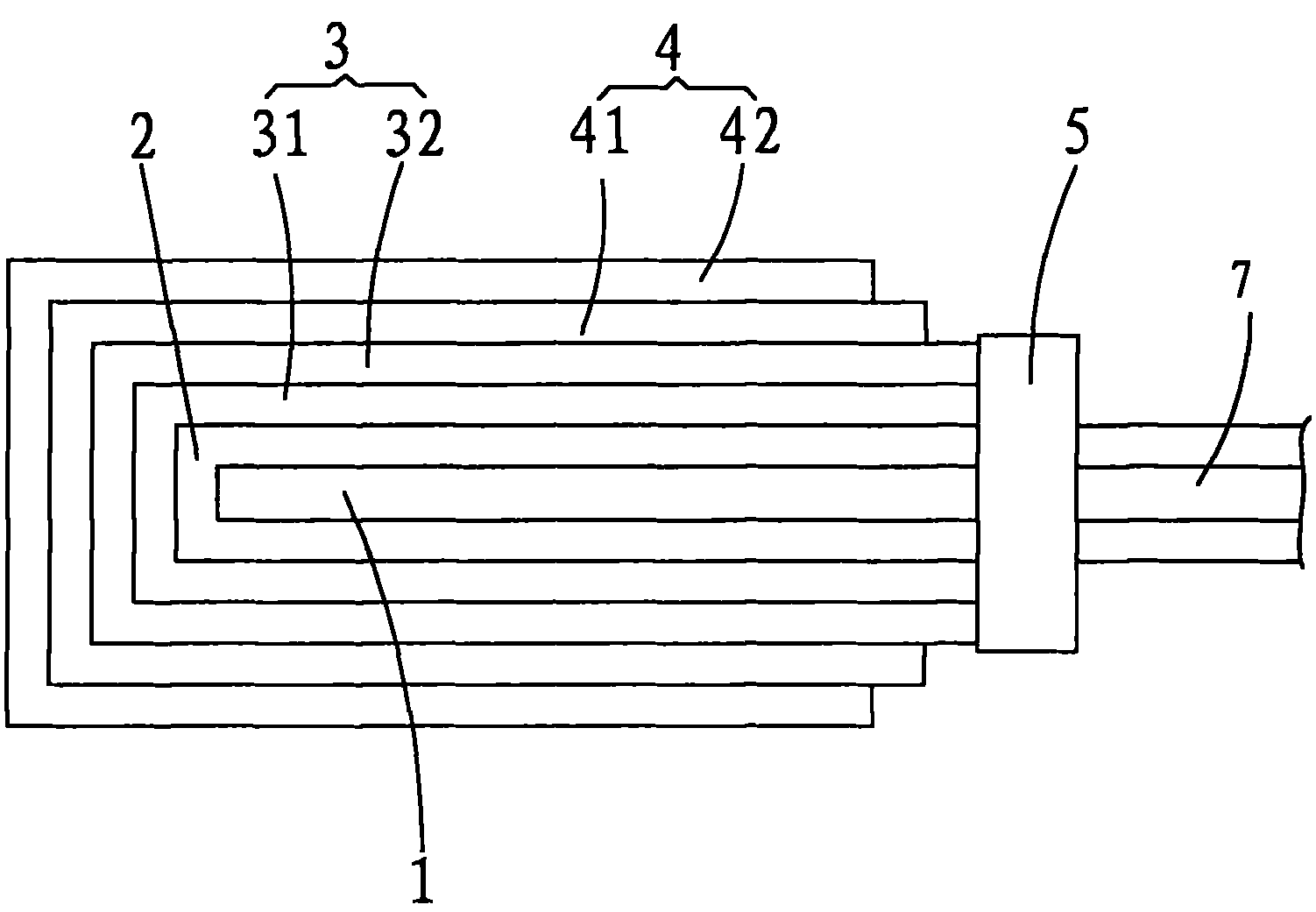

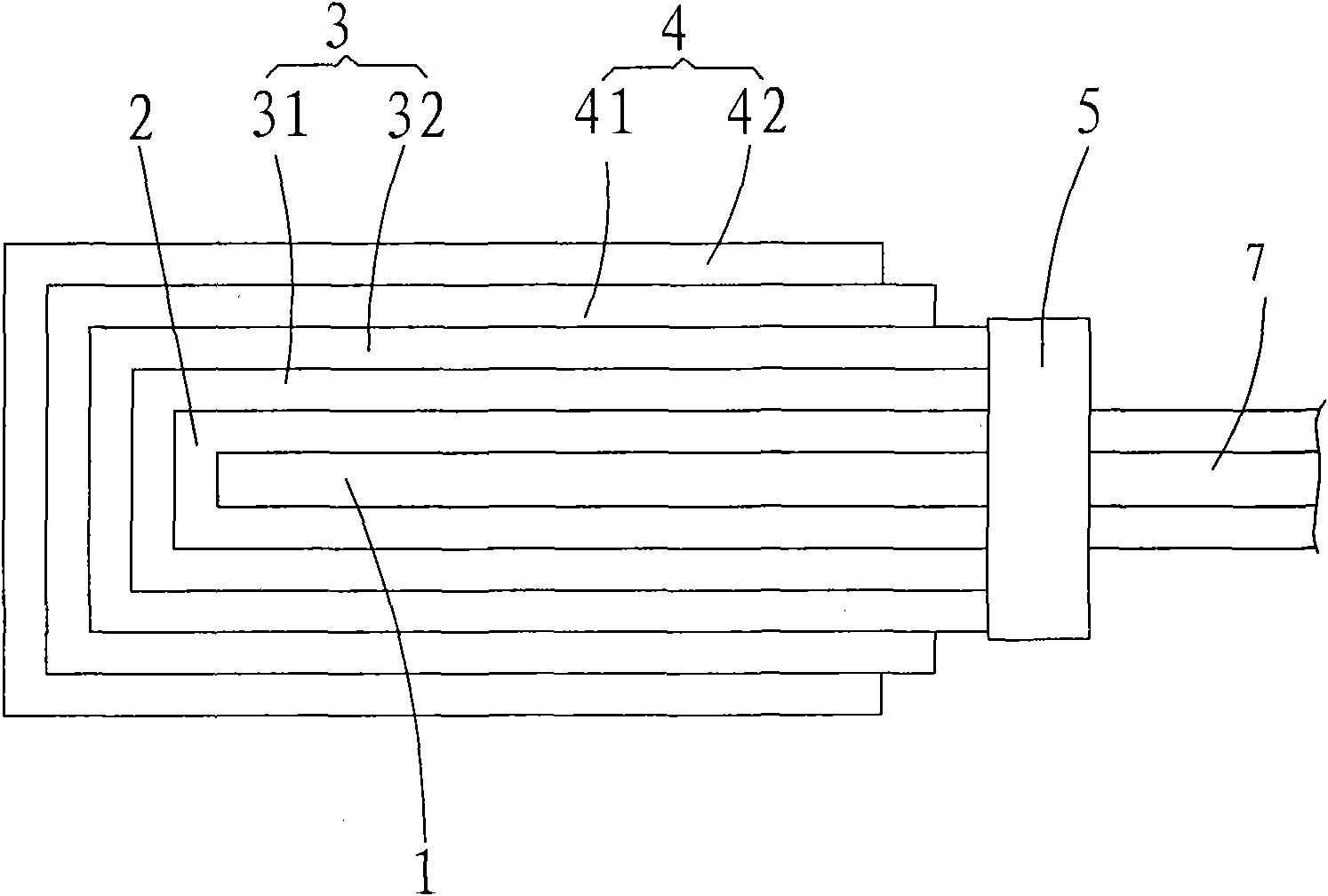

[0022] Please combine figure 1 and figure 2 As shown, the 13VF aluminum foil 6 including the anode body 1 and the oxide film medium 2 is cut into 3.5*9mm, and the anode electrode part 7 and the cathode electrode part 4 are separated by insulating glue 5 . The cathode electrode part 4 was completely immersed in the first electrolyte solution (referring to the electrolyte solution used before making the solid electrolyte layer) at 85°C for treatment, and a voltage of 13V was applied for 30min. Afterwards, the solid electrolyte layer 3 is prepared in the cathode region by a conventional method, and then the carbon layer 41 and the silver layer 42 are prepared to obtain a monolithic capacitor element. The first electrolytic solution among the present embodiment is by 150g / L ammonium adipate, accounts for the 1.0wt% stearyl stearate of electrolytic solution total amount, and the remainder is made up of water and ethylene glycol (the ratio of the two is 3:1). Among them, ammoniu...

Embodiment 2

[0025] Please combine figure 1 and figure 2 As shown, the 13VF aluminum foil 6 including the anode body 1 and the oxide film medium 2 is cut into a size of 3.5*9mm, and the anode electrode part 7 and the cathode electrode part 4 are separated by insulating glue 5 . The cathode electrode part 4 was completely immersed in the first electrolytic solution at 85° C. for treatment, and a voltage of 13 V was applied for 30 minutes. Afterwards, the solid electrolyte layer 3 is prepared by chemical polymerization in the cathode area, and the cathode electrode part 4 covering the solid electrolyte layer 3 is completely immersed in the second electrolyte solution at 25°C (referring to the electrolytic solution used in the process of making the solid electrolyte layer). solution), and applied a voltage of 13V for 30min. Then continue to prepare the solid electrolyte layer 3 by chemical polymerization, and then completely immerse the cathode electrode part 4 covering the solid electroly...

Embodiment 3

[0027] The difference from Example 1 is that the first electrolyte is composed of 10 g / L ammonium citrate, 0.001 wt% cetyltrimethylammonium bromide and the remaining water, accounting for the total amount of the electrolyte. Wherein, ammonium citrate is a chemical-forming electrolyte, cetyltrimethylammonium bromide is a cationic surfactant, and water is a solvent. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com