BIPV (Building Integrated Photovoltaics) solar module and manufacture method thereof

A technology for a solar cell module and a manufacturing method, which are applied in the fields of optoelectronics and building materials, can solve the problems of easy aging, affect the appearance of buildings, and can not achieve the effect of solving long-term aging and yellowing, the process is simple and practical, and the power generation efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

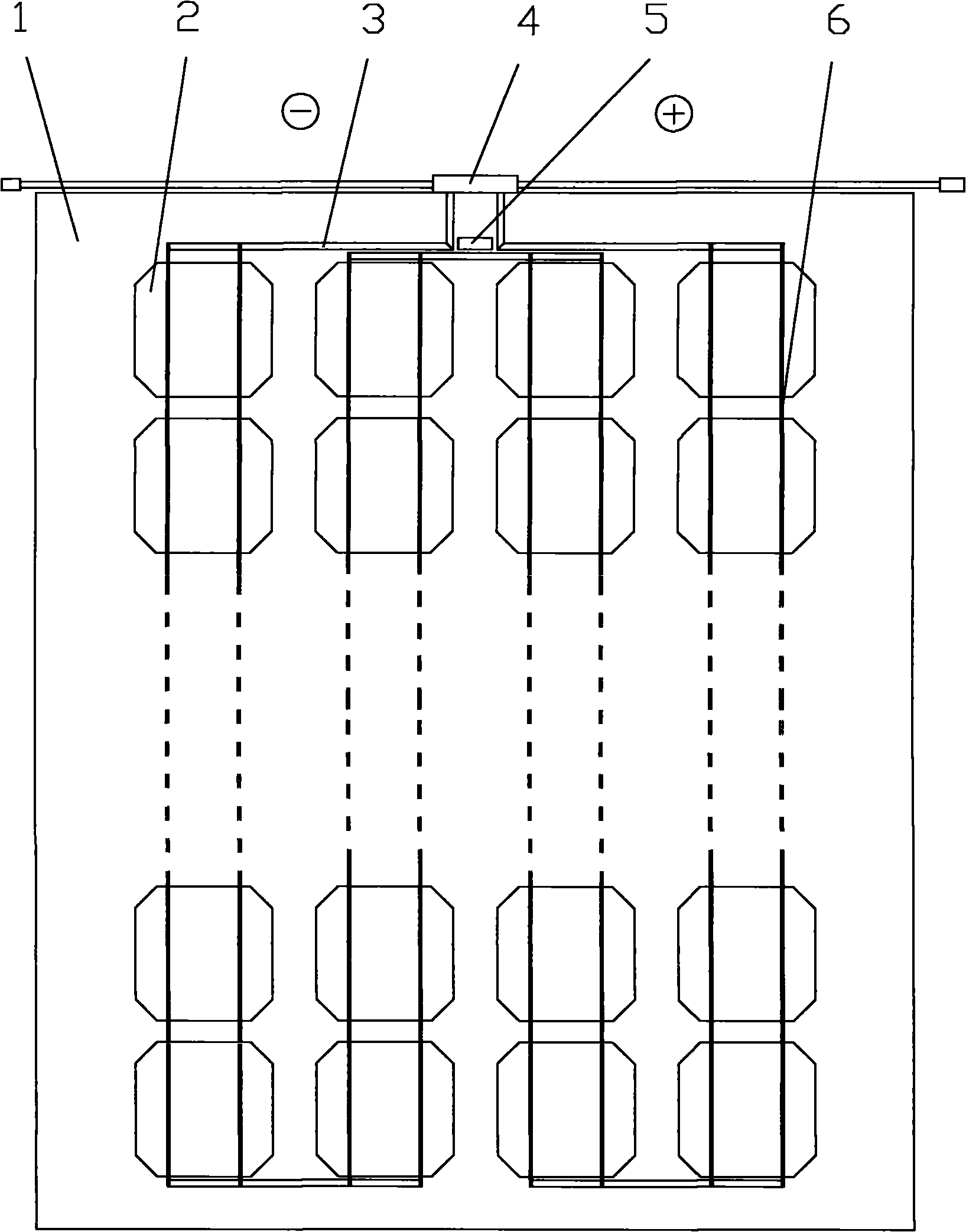

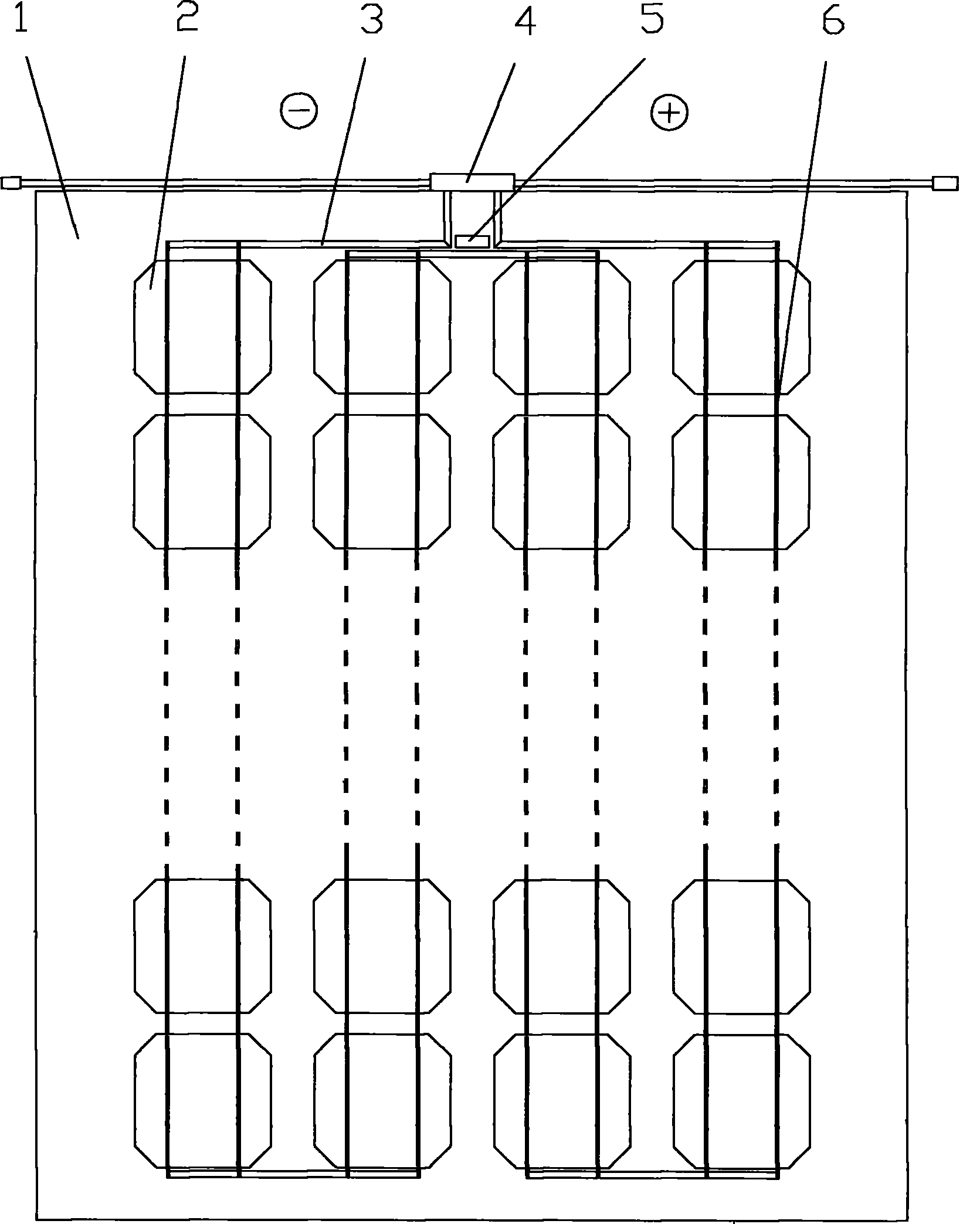

[0033] 1. Single-chip detection: control the temperature of the testing instrument at 25°C, conduct a constant-temperature electrical performance test on the front and back of the single-chip double-sided crystalline silicon solar cell 2, and perform power classification with a deviation of ±3%; In the embodiment, 24 double-sided crystalline silicon solar cells 2 with front and back photoelectric conversion efficiencies of 15% (power 2.25W) and 12% (power 2.25W) were selected.

[0034] 2. Single welding and series welding: Firstly, the selected double-sided crystalline silicon solar cells 2 are welded to the interconnection bars 6 of the front and back busbar lines, and then placed on the series welding platform to perform 6 pieces of double-sided crystalline silicon solar cells. A group of battery slices 2 are connected in series, and the spacing between the double-sided crystalline silicon solar battery slices 2 is controlled at 15mm.

[0035] 3. Stack typesetting: Lay a lay...

Embodiment 2

[0047] 1. Single-chip detection: control the temperature of the testing instrument at 25°C, conduct a constant-temperature electrical performance test on the front and back of the single-chip double-sided crystalline silicon solar cell 2, and perform power classification with a deviation of ±3%; In the embodiment, 24 double-sided crystalline silicon solar cells 2 with front and back photoelectric conversion efficiencies of 15% (power 2.25W) and 12% (power 2.25W) were selected.

[0048] 2. Single welding and series welding: Firstly, the selected double-sided crystalline silicon solar cells 2 are welded to the interconnection bars 6 of the front and back busbar lines, and then placed on the series welding platform to perform 6 pieces of double-sided crystalline silicon solar cells. A group of battery slices 2 are connected by serial welding, and the spacing between the double-sided crystalline silicon solar battery slices 2 is controlled at 10mm.

[0049] 3. Stack typesetting: L...

Embodiment 3

[0061] 1. Single-chip detection: control the temperature of the testing instrument at 25°C, conduct a constant-temperature electrical performance test on the front and back of the single-chip double-sided crystalline silicon solar cell 2, and perform power classification with a deviation of ±3%; In the embodiment, 24 double-sided crystalline silicon solar cells 2 with front and back photoelectric conversion efficiencies of 15% (power 2.25W) and 12% (power 2.25W) were selected.

[0062] 2. Single welding and series welding: Firstly, the selected double-sided crystalline silicon solar cells 2 are welded to the interconnection bars 6 of the front and back busbar lines, and then placed on the series welding platform to perform 6 pieces of double-sided crystalline silicon solar cells. A group of battery slices 2 are connected in series, and the spacing between the double-sided crystalline silicon solar battery slices 2 is controlled at 11mm.

[0063] 3. Lamination typesetting: Lay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com