Reflection-type TFT LCD and making method thereof

A liquid crystal display, reflective technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of uncontrollable bright state display of liquid crystal molecules, affecting normal display of pixels, low effective reflection area ratio, etc., to achieve large pixel reflection Effect of Display Area Area to Effective Reflection Area Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0060] The first embodiment: the upper surface of the pixel electrode is set as a reflective surface.

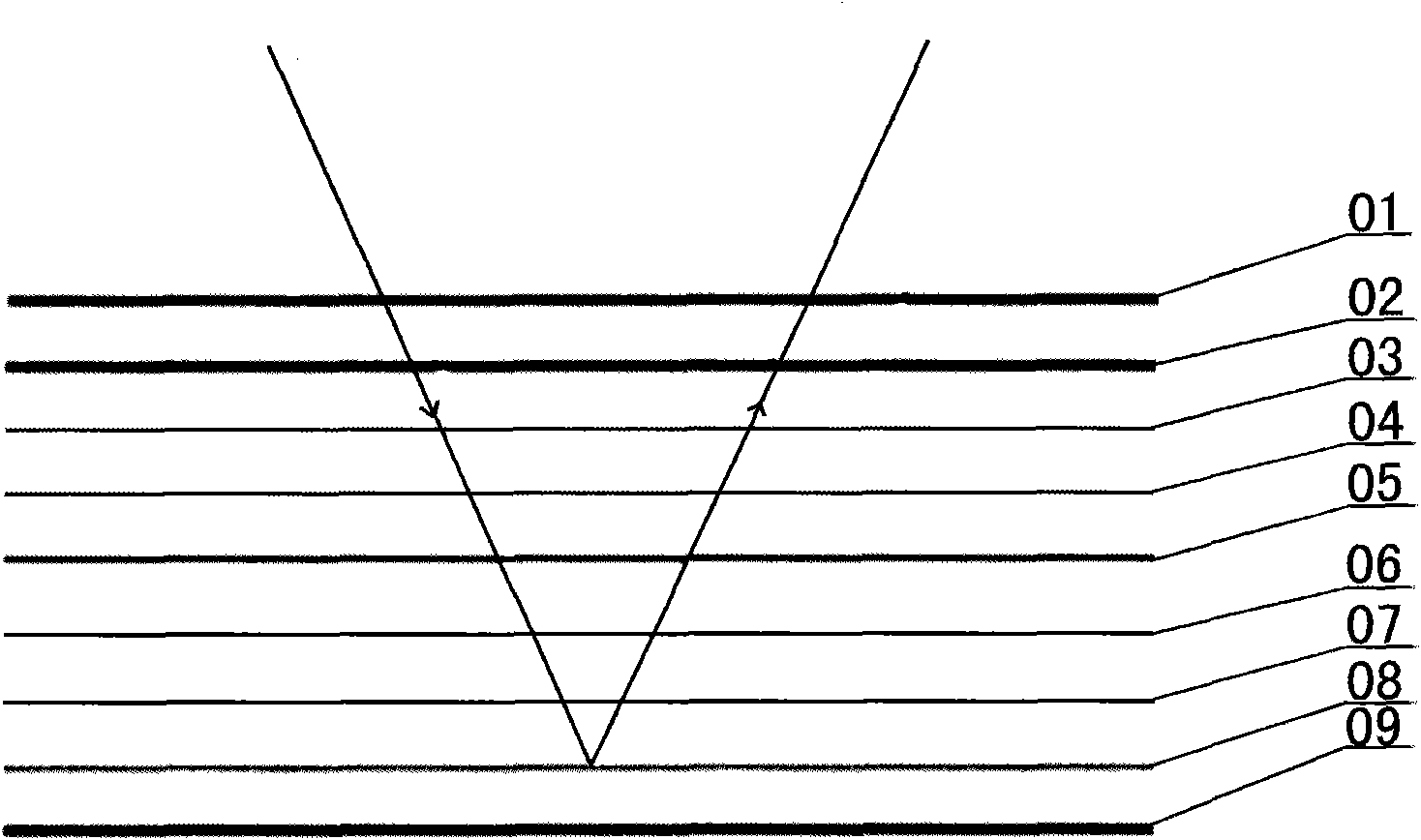

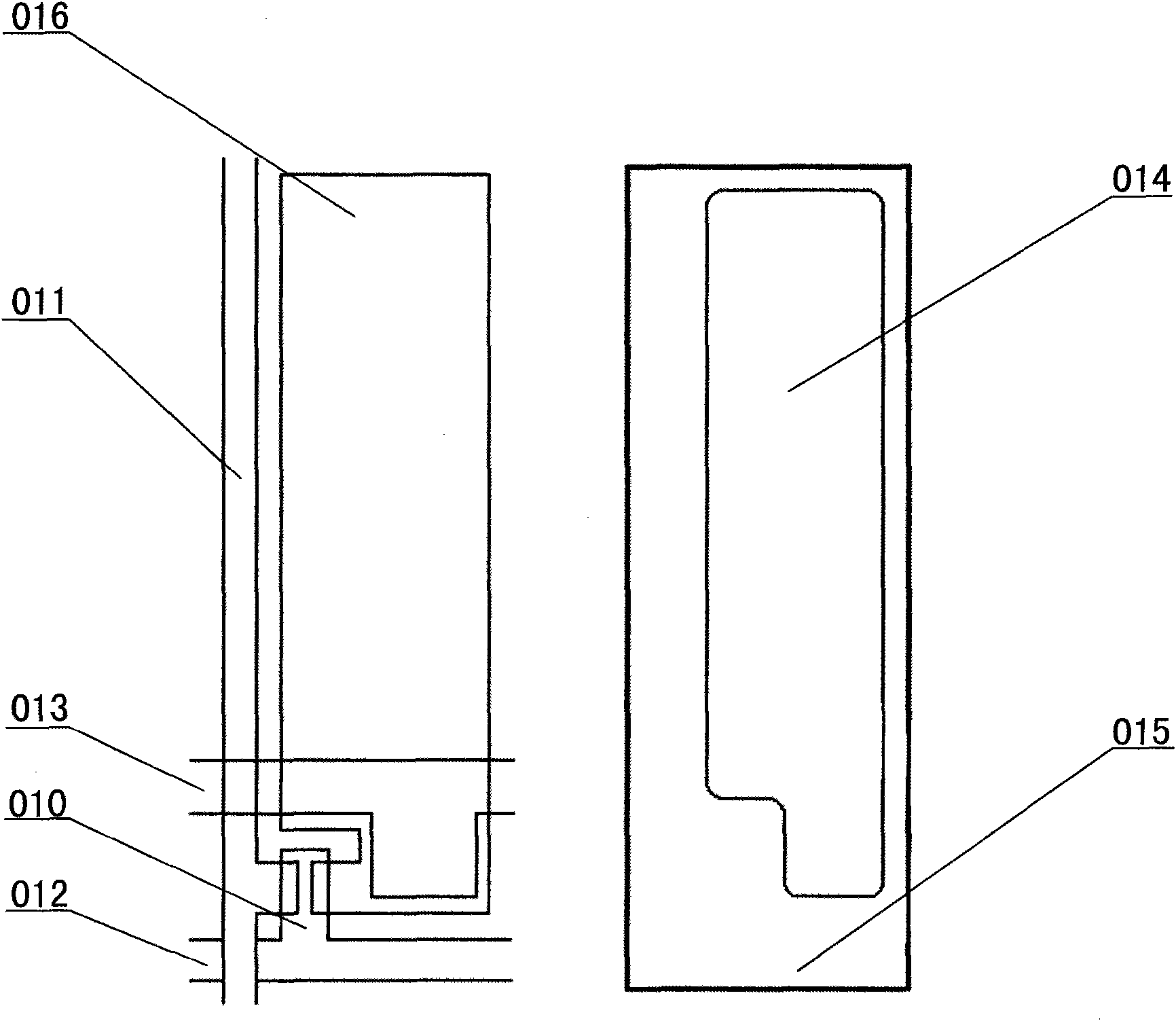

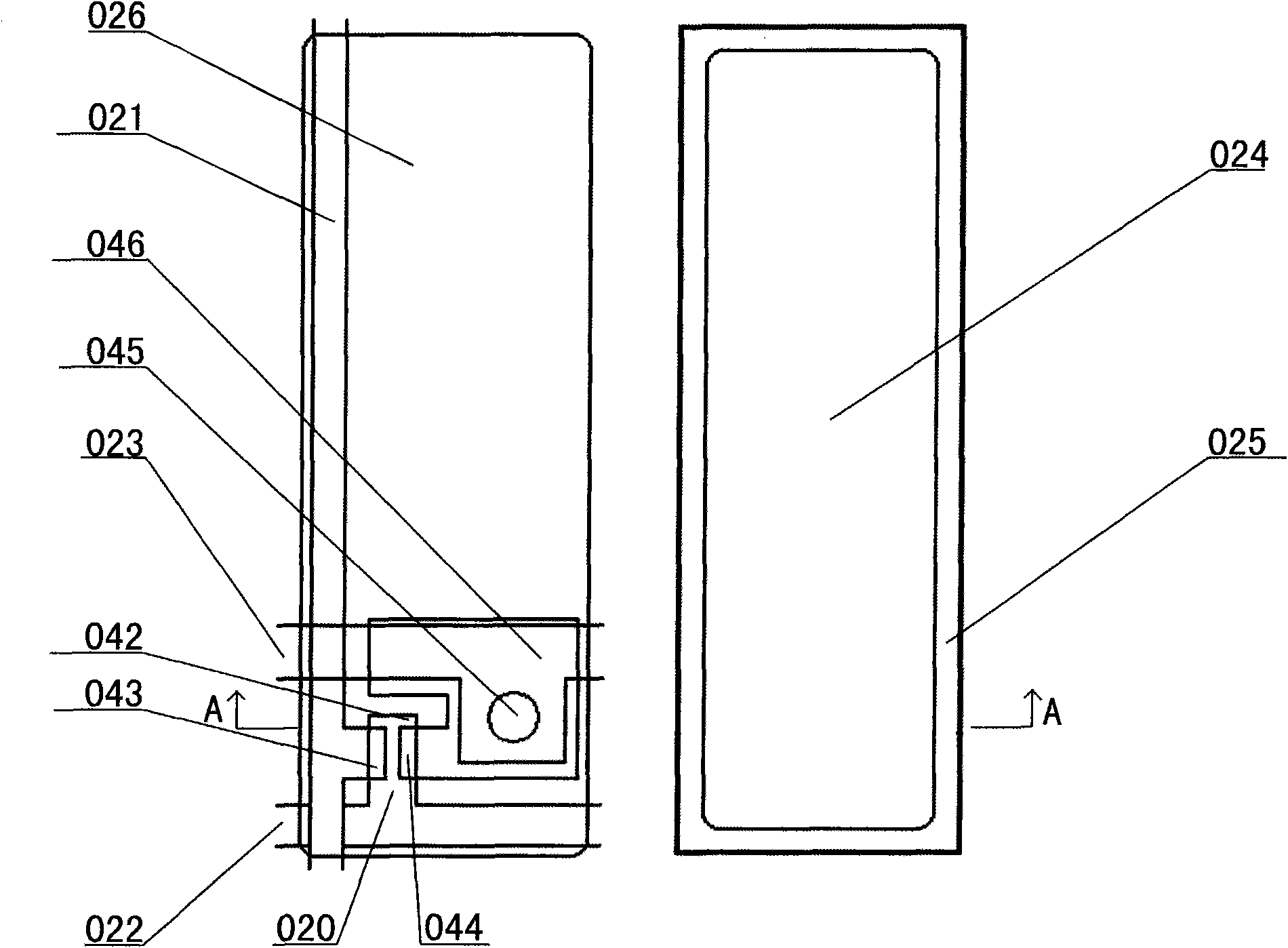

[0061] like Figure 7 As shown, the reflective TFT liquid crystal display of the first embodiment includes a lower substrate 10, a driving component layer 9, a light absorbing layer 8, a pixel electrode layer 7, a lower alignment layer 6, a liquid crystal layer 5, and an upper alignment layer arranged sequentially. The layer 4, the common electrode layer 3, the upper substrate 2, the polarizer 1, and the upper surface of the pixel electrode layer 7 constitute a reflective surface. The gap between two adjacent pixel electrodes 11 (that is, the gap between two adjacent reflective surfaces) constitutes a light absorption gap 13, and the light absorption gap 13 constitutes a black border area between two adjacent pixels because no li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com