Method for manufacturing sloped sidewall silicon dioxide structure by adopting photoetching and dry etching

A technology of silicon dioxide and dry etching, applied in the field of semiconductor technology, can solve the problems of unsuitable MEMS devices, easy to break, high equipment requirements, etc., achieve good electrical connection, avoid breakage, and have strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

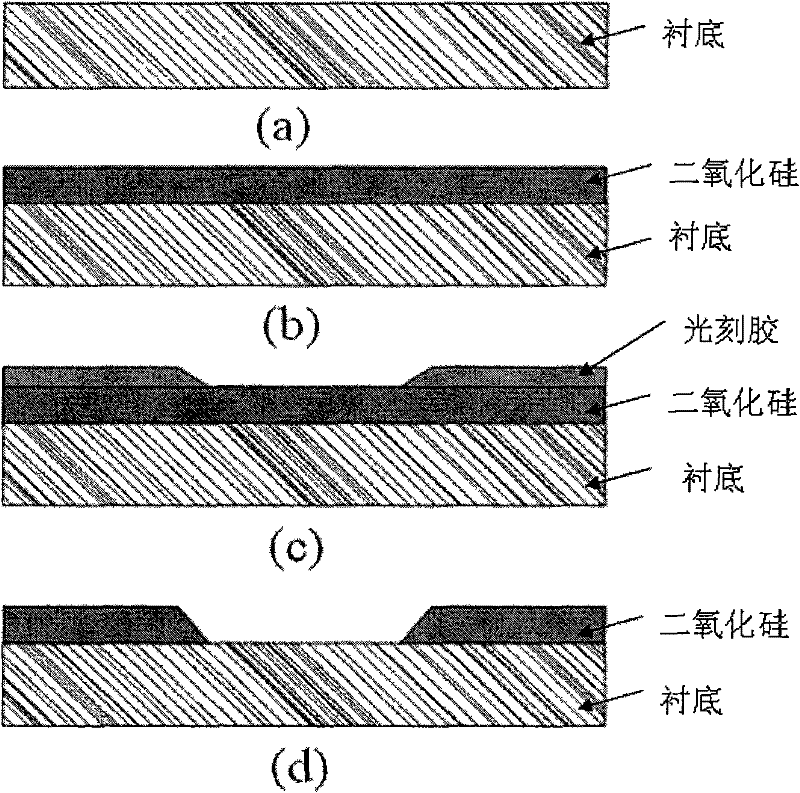

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

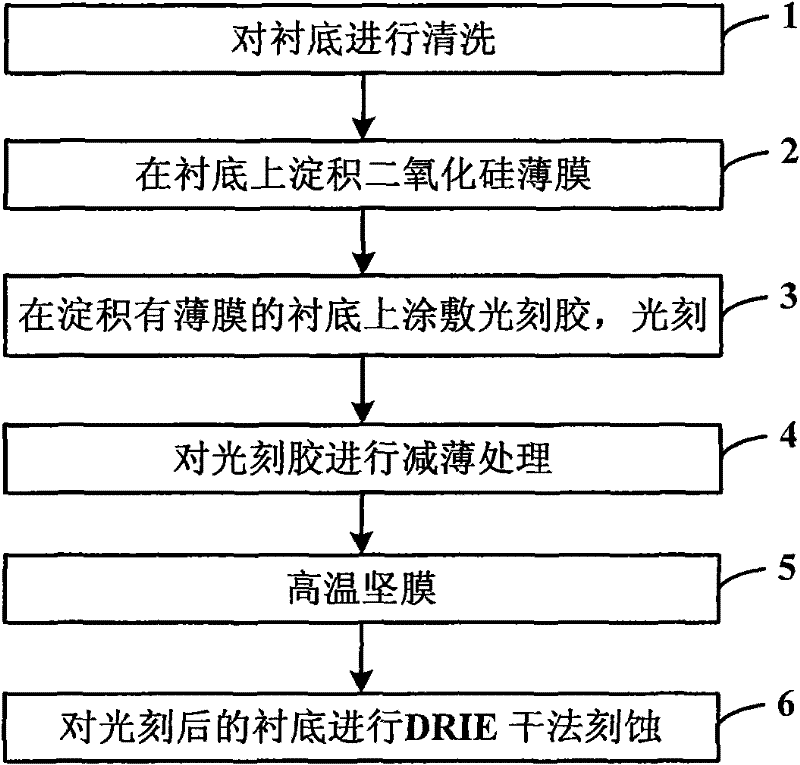

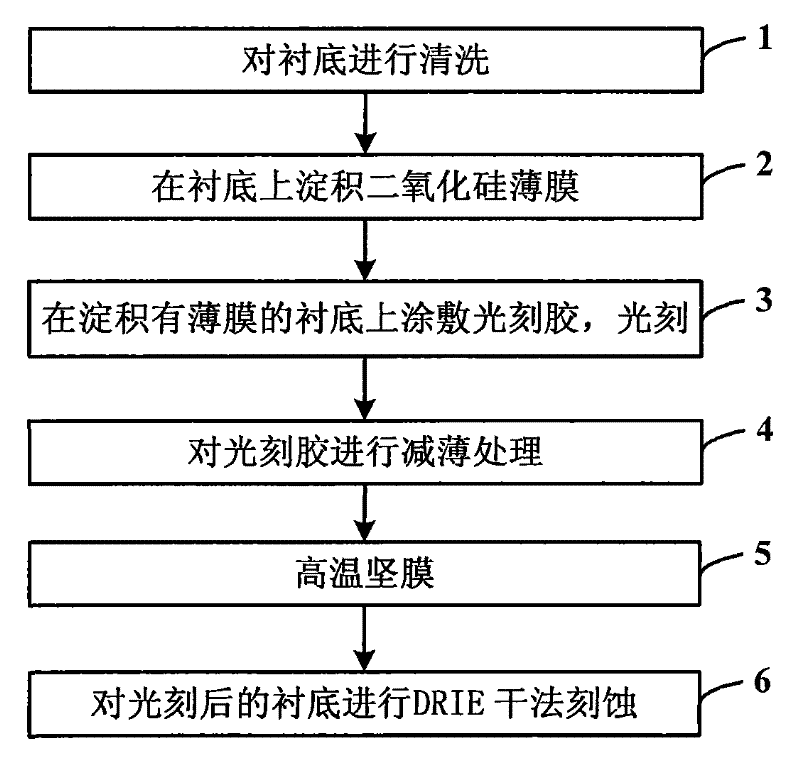

[0033] Such as figure 1 as shown, figure 1 It is a flow chart of a method for fabricating a silicon dioxide structure with inclined sidewalls by photolithography and dry etching provided by the present invention, and the method includes:

[0034] Step 1: cleaning the substrate;

[0035] For Si wafers or SOI wafers, the standard RCA cleaning process is used to clean the substrate; for quartz wafers, acetone, ethanol, and deionized water are used to clean the samples ultrasonically.

[0036] Step 2: Depositing a thin film on the substrate;

[0037] In this step, the substrate is placed in a plasma-enhanced chemical vapor deposition (PECVD) vacuum chamber and preheated for 5 minutes to raise the temperature of the substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com