Photographic paper base for double-sided imaging and double-sided sensitive color photographic paper containing same

A double-sided imaging, paper-based technology, applied in photosensitive materials, optics, instruments, etc., can solve the problems of increasing the production difficulty and manufacturing cost of double-sided photo paper, deterioration of the whiteness of double-sided photo paper, and reducing the image quality of photo paper, etc. , to achieve rich image levels, eliminate negative interference images, and good light blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

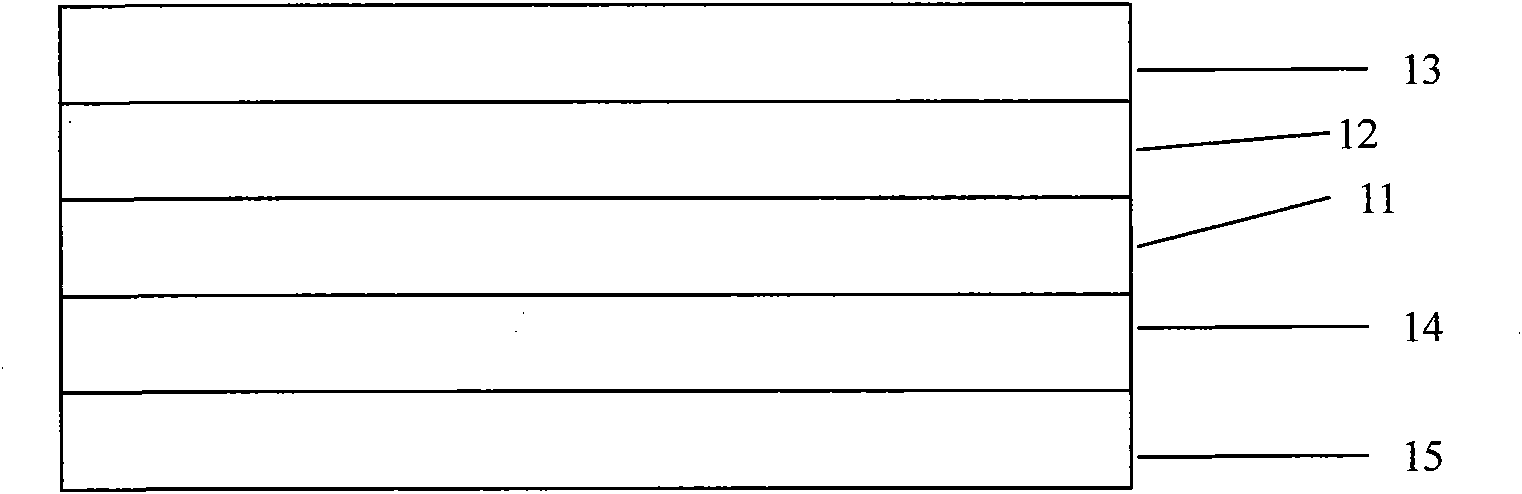

[0035] The preparation of photosensitive coating of the present invention adopts the known technology of color photographic paper to implement, specifically as follows:

[0036] The first layer (blue sensitive layer) Coating weight (g / m2)

[0037] Blue Sensitive Emulsion Silver 0.25

[0038] Gelatin 1.20

[0039] Yellow coupler D1 0.43

[0040] Image light stabilizer F1 0.10

[0041] Solvent R-1 0.30

[0042] Solvent R-2 0.20

[0043] Polymer A2 0.03

[0044] The second layer (compartment)

[0045] Gelatin 0.85

[0046] Anti-pollution agent KB-1 0.09

[0047] Solvent R-1 0.06

[0048] Solvent R-3 0.03;

[0049] The third layer (green layer)

[0050] Green Sensitive Emulsion Silver 0.10

[0051] Gelatin 1.00

[0052] Magenta coupler E1 0.25

[0053] Image light stabilizer F1 0.20

[0054] Solvent R-1 0.10

[0055] Solvent R-4 0.05

[0056] Polymer A2 0.03;

[0057] The fourth layer (ultraviolet absorber layer ①)

[0058] Gelatin 0.80

[0059] Anti-pollution ...

Embodiment 1

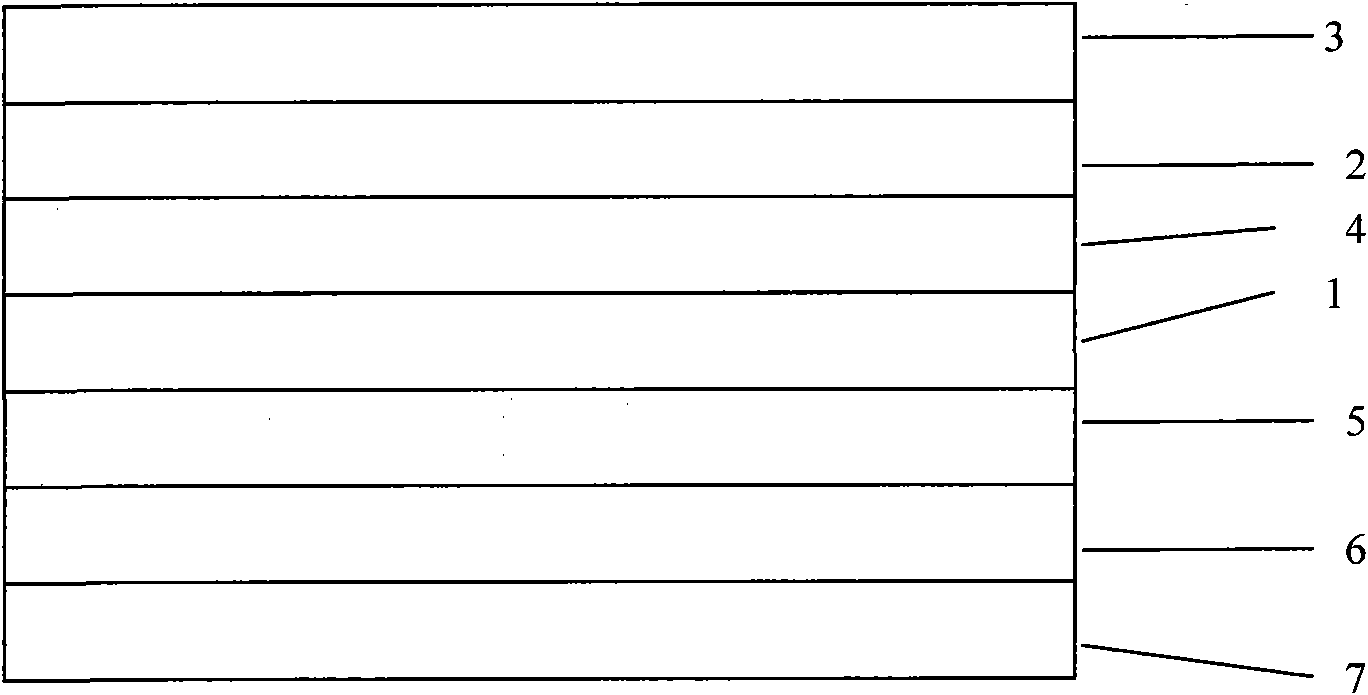

[0089] Using the transfer vacuum evaporation coating method, at 1.3×10 -2 ~1.3×10 -3 Heating high-purity aluminum in a vacuum environment of Pa makes the aluminum evaporate in a short time, and the aluminum wire evaporates into atoms under the action of high temperature of 1400 ° C, deposits on the resin film, and condenses into a fine and dense bright aluminum film after being cooled by a water-cooled roller. Adjust the time of vacuum deposition to control the thickness of the film, and then transfer the aluminum film to one side of the photographic base paper through adhesive transfer, compound the same aluminum film on the other side of the photographic base paper in the same way, and finally peel off the resin film.

[0090] Process the mixture of granular resin, white masterbatch and color masterbatch in a certain proportion into a molten body by extrusion and heating and pressure on the composited aluminum film, and then form a molten film through the action of the die h...

Embodiment 2

[0093] Using the magnetron sputtering coating method, at 1.3×10 -1 Nitrogen is filled in a vacuum of about Pa, and a high-voltage direct current is applied between the plastic substrate (anode, such as polyester film) and the metal target (cathode, such as metal tin), and the electrons generated by the discharge excite the inert gas to generate plasma. body, the plasma knocks out the atoms of the metal target sn and deposits it on the resin film to form a tin metal film, the thickness of the film is controlled by adjusting the deposition time, and the tin metal film is transferred to the base paper through a suitable adhesive On one side; peel off the resin film and transfer the tin metal film to the other side of the photographic base paper in the same way.

[0094] Process the mixture of granular resin, white masterbatch and color masterbatch in a certain proportion into a molten body through extrusion and heating and pressure on the composited tin film, and then make it int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com