Anti-scratch energy-saving fireproof glass

A fire-resistant glass and anti-scratch technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of increased energy consumption, low safety, inconvenient use, etc., to reduce scratches, realize energy saving, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

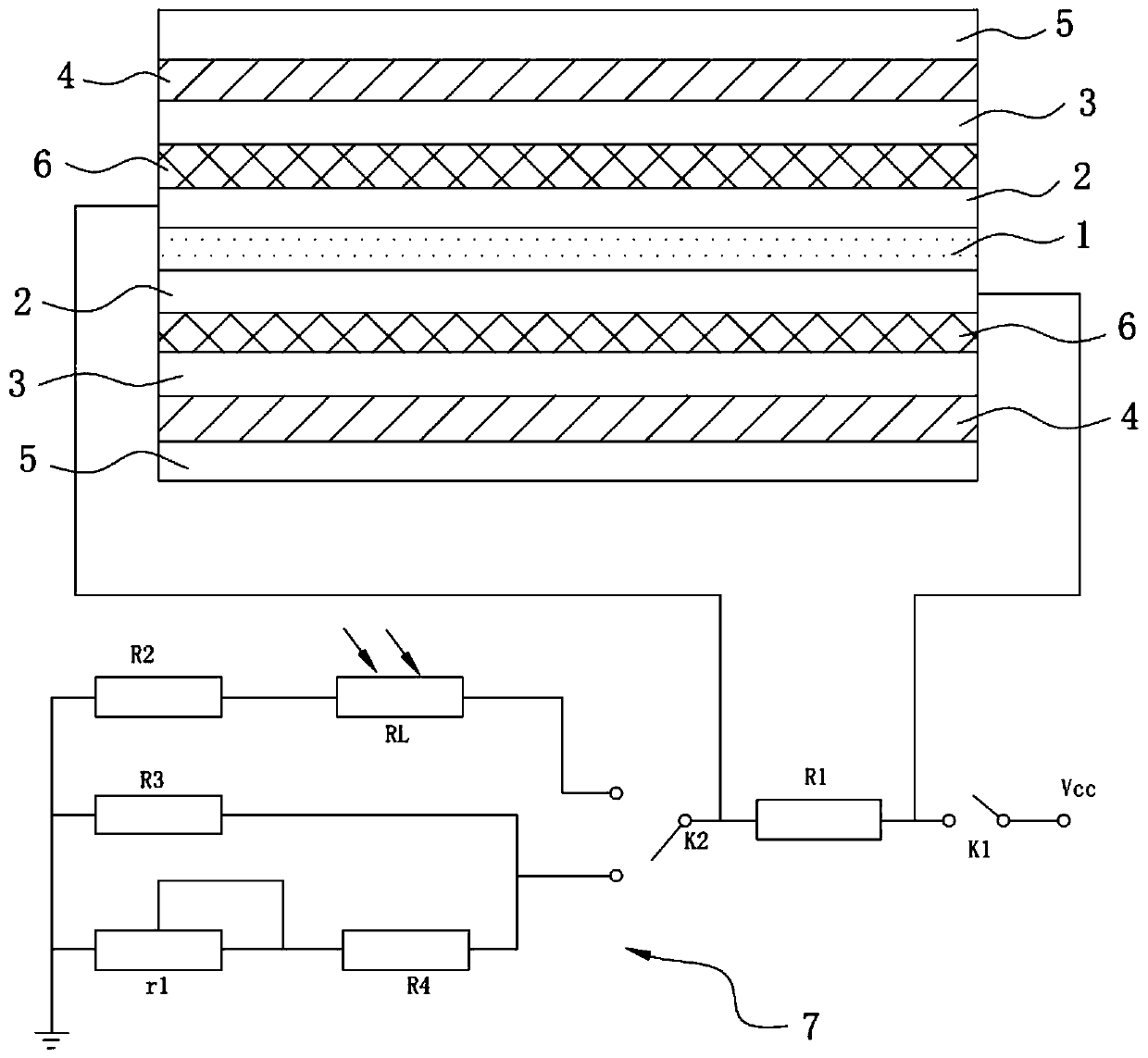

[0037] refer to figure 1 , this embodiment provides a scratch-resistant energy-saving fireproof glass, including a control circuit 7 and a glass body, and the glass body includes:

[0038] Liquid crystal layer 1;

[0039] The transparent electrode layer 2 is respectively compounded on both sides of the liquid crystal layer 1;

[0040] The fireproof layer 3 is compounded on the side of the transparent electrode layer 2 facing away from the liquid crystal layer 1;

[0041] The fireproof glass layer 4 is compounded on the side of the fireproof layer 3 facing away from the transparent electrode layer 2;

[0042] The anti-scratch layer 5 is formed on the side surface of the fireproof glass layer 4 facing away from the fireproof layer 3 through a sputtering process;

[0043] The control circuit 7 includes;

[0044] Control switch K1;

[0045] An automatic circuit comprising a photoresistor RL and a second resistor R2 connected in series;

[0046] The manual circuit includes a ...

Embodiment 2

[0064] The difference between this embodiment and the above embodiments is that the thickness of the liquid crystal layer 1 of this embodiment is 6 μm, and the transparent conductive layer is SnO 2 The thickness of the film is 0.8 μm, and the SnO2 film has a thicker acid corrosion resistance. Among them, the anti-scratch layer 5 is a carbon nitride layer. The hardness of the carbon nitride material can be comparable to that of diamond. The surface of the product can effectively enhance the anti-scratch and anti-scratch effect of the product.

Embodiment 3

[0066] The difference between this embodiment and the above embodiments is that the thickness of the liquid crystal layer 1 of this embodiment is 9 μm, and the transparent conductive layer is SnO 2 The thickness of the film is 1.1 μm, and the SnO2 film has good acid corrosion resistance. Wherein, the anti-scratch layer 5 is a polyester film layer. Specifically, the polyester film layer is composed of 80 parts by weight of hydroxy internal vinyl acid resin, amino resin 9 parts by weight, 4 parts by weight of nano silicon dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com