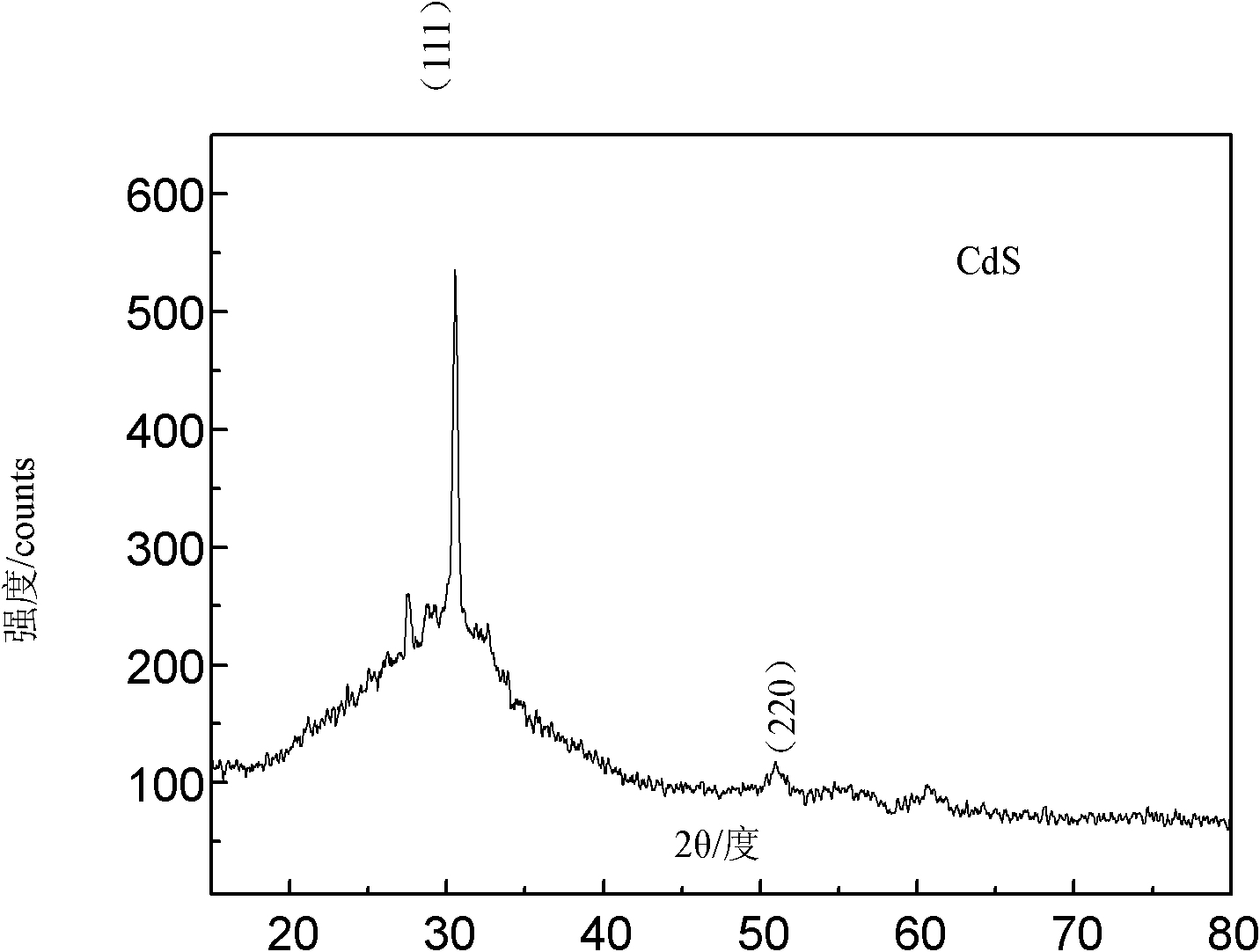

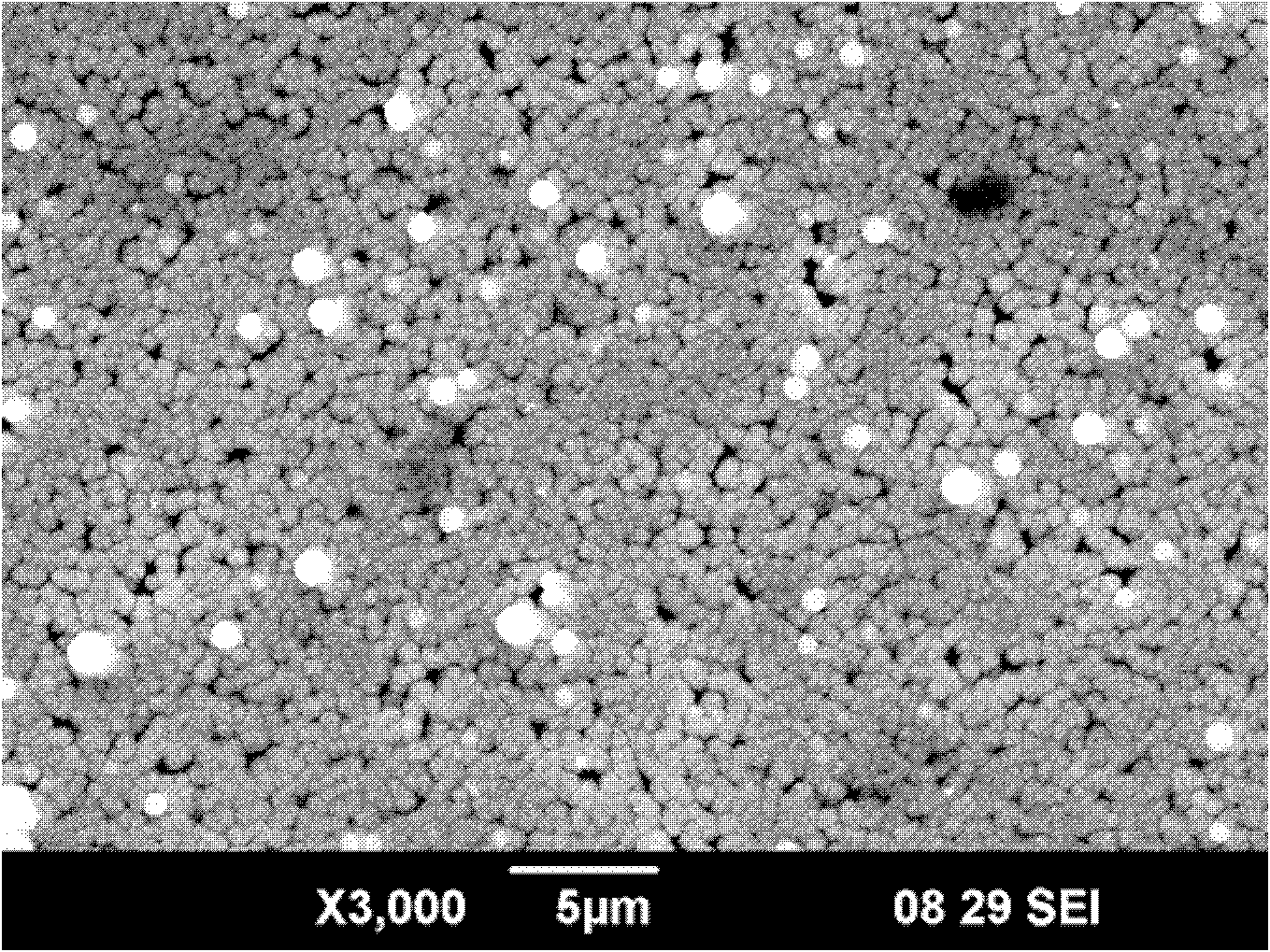

Method for preparing spherical cadmium sulfide (CdS) semiconductor film

A semiconductor and thin film technology, which is applied in the field of preparing CdS thin films, can solve the problems of high equipment requirements, complex processes, expensive equipment and instruments, etc., and achieve the effects of good uniformity, high film purity, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: 1) get 0.06mmol analytically pure cadmium acetate (C 4 h 6 CdO 4 ) is placed in a beaker, then in the beaker, add 5mL oleic acid dropwise and stir evenly, then add 40mL distilled water, and obtain a uniform solution A after ultrasonic dispersion; 2) add 0.6mmol analytically pure sodium thiosulfate pentahydrate ( Na 2 S 2 SO 3 ·5H 2 0) add distilled water again to make the total volume of the solution be 100mL and keep stirring, and obtain solution B after ultrasonic dispersion; 3) add analytically pure film-forming aid polyvinylpyrrolidone (PVP) to the B solution, so that the concentration of PVP is 0.005 mol / L, using HCl solution to adjust the pH value to 2.5 and form a uniform sol C after ultrasonication; 4) Clean the ITO glass with ultrasonic vibration in water and absolute ethanol respectively, and then in 70% sol with a volume ratio of 1:1 Nitric acid and a concentration of 30% hydrogen peroxide in the activation solution soak activation treatme...

Embodiment 2

[0013] Embodiment 2: 1) get 0.08mmol analytically pure cadmium acetate (C 4 h 6 CdO 4 ) is placed in a beaker, then in the beaker, add 5mL oleic acid dropwise and stir evenly, then add 40mL distilled water, and obtain a uniform solution A after ultrasonic dispersion; 2) add 1.2mmol analytically pure sodium thiosulfate pentahydrate ( Na 2 S 2 SO 3 ·5H 2 0) add distilled water again to make the solution total volume be 100mL and keep stirring, obtain solution B after ultrasonic dispersion; 3) add analytically pure film-forming aid polyvinylpyrrolidone (PVP) in B solution, make the concentration of PVP be 0.006 mol / L, use HCl solution to adjust the pH value to 3.0, and form a uniform sol C after ultrasonication; % nitric acid and a concentration of 30% hydrogen peroxide in the activation solution soaked in the activation treatment for 10 minutes; 5) the glass slide after the activation treatment was fixed on the cathode of the electrodeposition device, immersed in sol C, an...

Embodiment 3

[0014] Embodiment 3: 1) get 0.05mmol analytically pure cadmium acetate (C 4 h 6 CdO 4 ) is placed in a beaker, then in the beaker, add 5mL oleic acid dropwise and stir evenly, then add 40mL distilled water, and obtain a uniform solution A after ultrasonic dispersion; 2) add 0.5mmol analytically pure sodium thiosulfate pentahydrate ( Na 2 S 2 SO 3 ·5H 20) add distilled water again to make the solution total volume be 100mL and keep stirring, obtain solution B after ultrasonic dispersion; 3) add analytically pure film-forming aid polyvinylpyrrolidone (PVP) in B solution, make the concentration of PVP be 0.0025 mol / L, use HCl solution to adjust the pH value to 2.0, and form a uniform sol C after ultrasonication; 4) Clean the Si substrate by ultrasonic vibration in water and absolute ethanol, and then 70% sol at a volume ratio of 1:1 Nitric acid and a concentration of 30% hydrogen peroxide in the activation solution soaking activation treatment for 10 minutes; 5) the Si subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com