Low-cost carbon graphene sheet and preparation method thereof

A graphene sheet, low-cost technology, applied in the field of low-cost carbon graphene sheet and its preparation, can solve the problems that hinder the popularization and application of graphene sheet, high cost of graphene sheet preparation, difficulty in large-scale preparation of graphene sheet, etc. , to achieve the effect of easy large-scale production, abundant raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

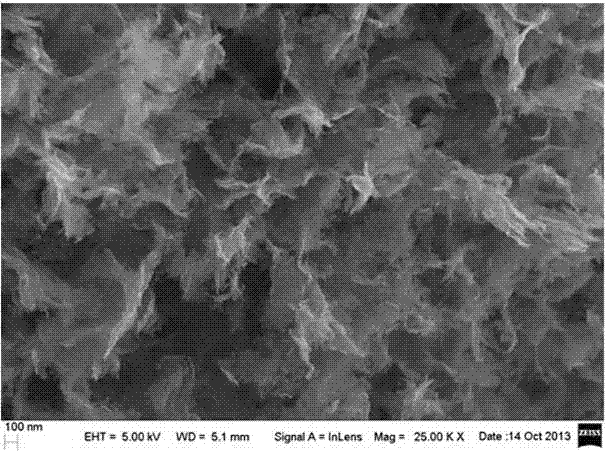

Embodiment 1

[0048] Weigh anthracite and alumina at a ratio of 100:50 (mass ratio), grind to 600 mesh, put it into a crucible, cover it and move it into a vacuum furnace, and evacuate until the vacuum degree reaches 1.0×10 2 Pa, then raise the temperature at 20°C / min to 2000°C, keep it warm for 2h, cool to room temperature, and take out the charred product. Put the vacuum carbonized product in hydrochloric acid with a pH value of 1 (the mass ratio of carbonized product to hydrochloric acid is 1:2), stir for 1 h (stirring speed 500 rpm), and then wash it fully with deionized water after separation by filtration until there is no Cl - It was detected that the graphene sheets were obtained by placing them in an oven at 110°C for 5 hours, and then putting them into a ball mill for 10 hours of ball milling (ball milling speed 1000 rpm). The prepared graphene sheet has the following properties: yield 62.4%, number of layers 2-6, carbon content 98.5%, specific surface area 346m 2 / g.

Embodiment 2

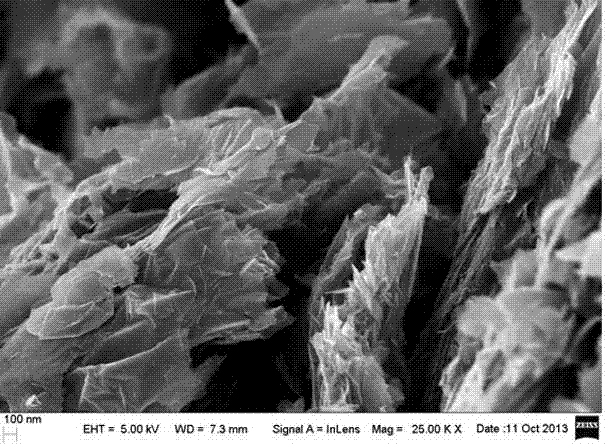

[0050] Weigh the petroleum coke and tin powder according to 100:10 (mass ratio), grind to 200 mesh, put it into the crucible, cover the lid and move it into the vacuum furnace, and evacuate until the vacuum degree reaches 1.0×10 1 Pa, then raise the temperature to 2400°C at 10°C / min, keep it warm for 1h, cool down to room temperature, and take out the charred product. Put the vacuum carbonized product in hydrochloric acid with a pH value of 3 (the mass ratio of carbonized product to hydrochloric acid is 1:3), stir for 5 hours (stirring speed 100 rpm), and after filtration and separation, fully wash with deionized water until there is no Cl - It was detected that the graphene sheets were obtained by placing them in an oven at 150°C for 2 hours, and then putting them into a ball mill for 6 hours of ball milling (ball milling speed 500 rpm). The prepared graphene sheet has the following properties: 40% yield, 5-10 layers, 98.0% carbon content, and 128m2 specific surface area 2 ...

Embodiment 3

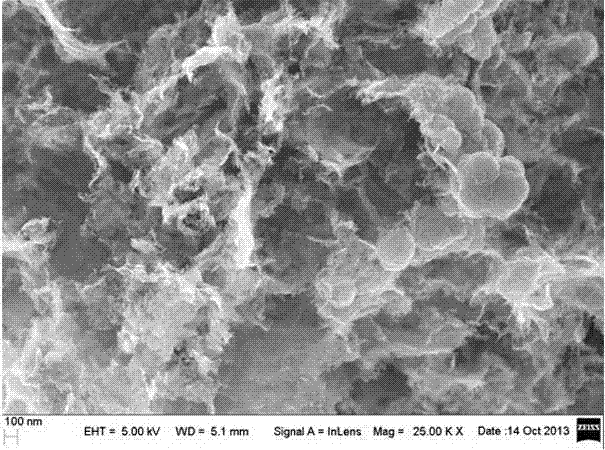

[0052] Weigh flake graphite powder and magnesium powder according to 100:20 (mass ratio), grind them to 60 mesh, put them into a crucible, cover them and move them into a vacuum furnace, and evacuate until the vacuum degree reaches 1.0×10 -1 Pa, then raise the temperature at 30°C / min to 1800°C, keep it warm for 5h, cool to room temperature, and take out the charred product. Put the vacuum carbonized product in hydrochloric acid with a pH value of 5 (mass ratio of carbonized product to hydrochloric acid 1:5), stir for 4 hours (stirring speed 50 rpm), and wash with deionized water after separation by filtration until there is no Cl - It was detected that the graphene sheets were obtained by placing them in an oven at 200°C for 1 h, and then putting them into a ball mill for 4 h (ball milling speed 700 rpm). The prepared graphene sheet has the following properties: yield 76.2%, number of layers 5-10, carbon content 99.0%, specific surface area 205m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com