Elastomeric product for modifying common soil and production method thereof

A production method and elastomer technology, applied in the direction of elastic flooring, textiles and papermaking, fibrous fillers, etc., to achieve the effects of improved dispersion, improved cross-linking, and increased effective cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

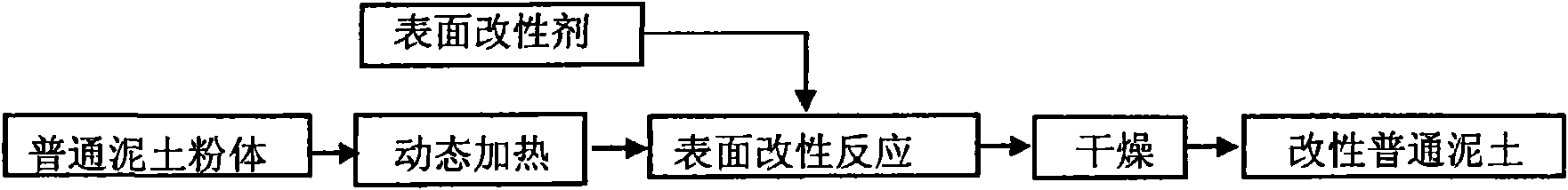

Method used

Image

Examples

Embodiment 1

[0101] Collect clean red mud, dry, pulverize and pass through a 100-800 mesh sieve to remove stones, gravel and sundries to obtain mud powder; Got mud. The surface modifier is 1 part of silane coupling agent vinyltrichlorosilane, and the polysiloxane with reactive functional groups is selected from -(CH 2 ) 3 (weight) parts of hydroxyalkyl polysiloxane of n OH, 1 (weight) part of fatty amide alkyl silane, add 96 (weight) parts of water and stir to obtain surface modifier; First, carry out dynamic ( Fluidized bed) heating, when the temperature reaches 80 ℃-130 ℃, under its high-speed dynamic condition, according to the weight of 70 parts of red mud, add 30 (weight) parts of surface modifier to the red mud powder by atomization , should be kept between 80-130 ℃, and continue to boil in the fluidized bed for 2 to 6 minutes to obtain surface-modified soil powder.

Embodiment 2

[0103]Collect clean yellow mud, dry, pulverize, pass through a 100-800 mesh sieve to remove stones, gravel and sundries to obtain mud powder; Got mud. The surface modifier is 2 parts by weight of silane coupling agent β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, and the polysiloxane with reactive functional groups is made of -(CH2)3OCH( OH) CH2OH of 5 (weight) parts of hydroxy alkyl polysiloxane, 0.5 (weight) part of fatty amide alkyl silane, adding 92.5 parts of water and stirring to obtain a surface modifier; first, carry out a dynamic (fluidized bed) process to the yellow mud powder. ) heating, when the temperature reaches 80 ℃-130 ℃, under its high-speed dynamic condition, according to the weight of 80 parts of yellow mud powder, 20 (weight) parts of surface modifier are added to the red mud powder by atomization method. Keep the temperature between 80-130 DEG C, and continue to boil in the fluidized bed for 2-6 minutes to obtain surface-modified loess clay powder.

Embodiment 3

[0105] Collect clean white mud, mix with water, pass through 100-800 mesh sieve to make mud, then dry and pulverize to get mud powder; Mud powder. The surface modifier is 0.8 part by weight of 3-(methacryloyloxy)propyltrimethoxysilane, a silane coupling agent, and 6 (by weight) of carboxypolysiloxane is used as the polysiloxane with reactive functional groups. parts, 0.7 parts by weight of fatty amide alkyl trialkoxysilane, add 92.5 parts of water and stir to obtain a surface modifier; first, the white mud is dynamically (fluidized bed) heated, and when the temperature reaches 80 ℃-130 ℃, Under its high-speed dynamic condition, according to the weight of 80 parts of white mud powder, add 20 (weight) parts of surface modifier to the white mud powder by atomization, it should be kept between 80-130 ℃, and continue to flow The chemical bed is boiled, and the holding time is 2 to 6 minutes to obtain the surface-modified white clay powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com