Thermoplastic halogen-free flame retarding elastomer composition for electric wire and cable covering materials

A covering material, wire and cable technology, applied in the direction of insulating cables, plastic/resin/wax insulators, cables, etc., can solve the problems of sticky surface of wire and cable, easy to stick dust, increase production cost, etc., and achieve excellent thermal deformation resistance , Improve flame retardant performance, excellent scratch resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

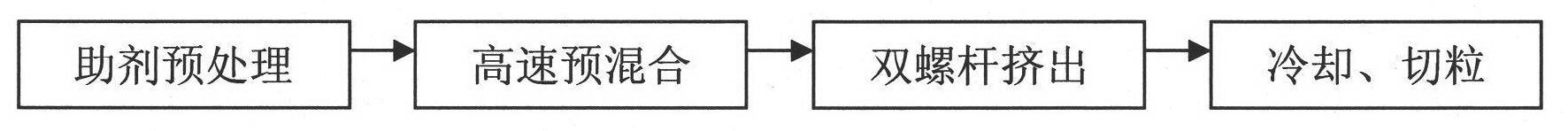

[0036] The preparation of the above-mentioned samples was carried out using the process described in Method 1. The details are as follows: Weigh polyphenylene ether resin, styrene-based elastomer, polyolefin resin, halogen-free flame retardant, flame retardant synergist, compatibilizer and other additives in sequence by mass parts and add them into the high-speed mixer together , after continuous stirring and mixing at room temperature for 10 minutes, extrude through a co-rotating twin-screw extruder in the range of 220 ° C to 250 ° C, and granulate after water cooling.

[0037] The formula, composition ratio and performance test result of table 1 embodiment 1-5 and comparative example 6-7

[0038]

[0039]

[0040] The performance test method of gained sample is as follows: (1) hardness: carry out according to ASTMD2240 standard, read the Shore durometer value after delaying 15 seconds; (2) Tensile property: carry out according to ASTM D412 standard, tensile speed 200mm...

Embodiment 1

[0042] The matrix hard resin adopts polyphenylene ether resin, the elastomer adopts hydrogenated polystyrene-b-butadiene-b-styrene (SEBS), the polyolefin adopts polypropylene, the compatibilizer adopts maleic anhydride grafted SEBS, flame retardant Melamine-coated nitrogen-phosphorus compound flame retardant was used as the agent, and tripentaerythritol was used as the flame-retardant synergist. See Example 1 in Table 1 for other components and proportions. The performance test results show that the obtained sample has good comprehensive mechanical properties, the flame retardancy meets the corresponding requirements of the UL test standard, and the surface of the sample has good scratch resistance.

Embodiment 2

[0044] On the basis of Example 1, only the type of polyolefin was changed, that is, polyethylene was used instead of polypropylene, and the rest of the components and ratios remained unchanged (see Table 1, Example 2). The performance test results show that compared with sample 1, due to the introduction of polyethylene, the strength and modulus of the sample are slightly reduced, but the toughness is improved, and the flame retardancy of the sample remains basically unchanged, that is, the sample can meet the requirements of various Item usage requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com