Micro-needle array chip and percutaneous administration patch using same and preparation method thereof

A technology of microneedle array and chip, which is applied in the direction of microneedles, medical formulas, needles, etc., can solve the problems of low cost, achieve low cost, facilitate puncture, and facilitate diffusion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Microneedle array chip and its preparation method

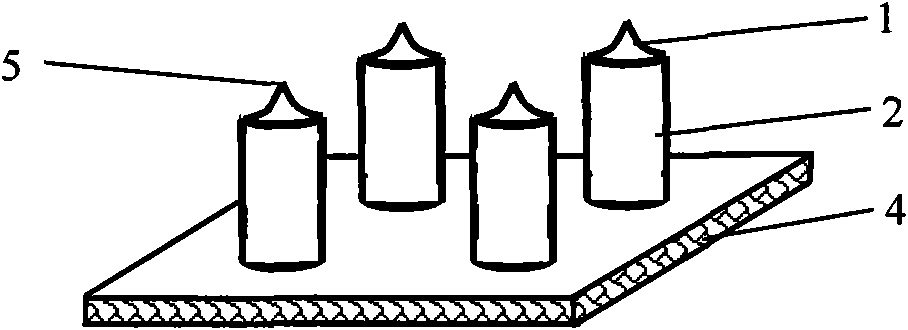

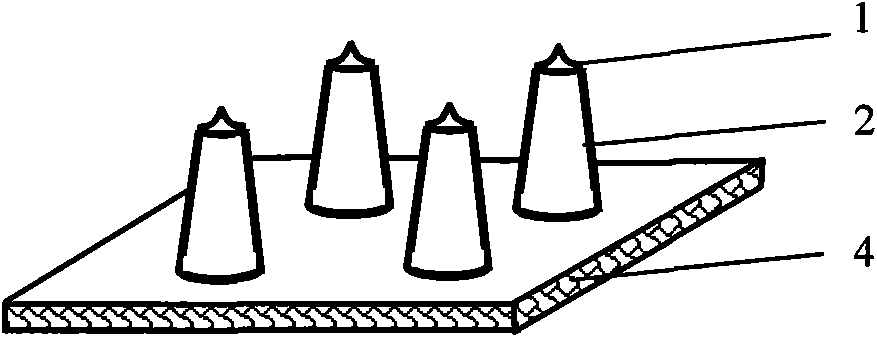

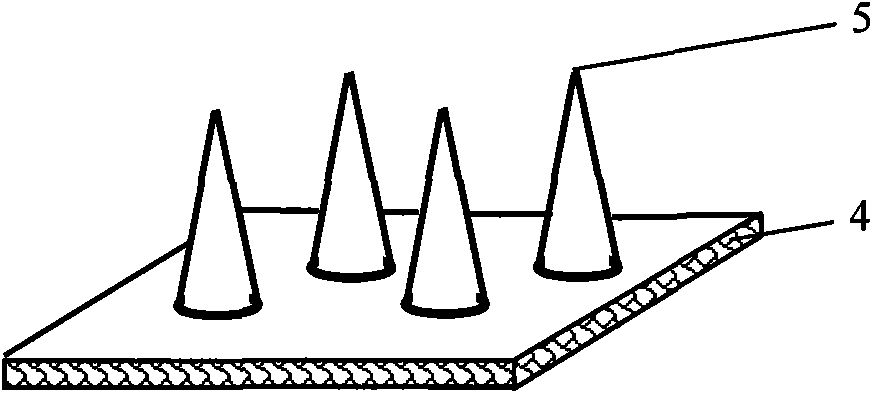

[0094] The microneedle array chip includes a microneedle and a substrate 4. The microneedle is composed of a needle head 1, a needle bar 2 and a needle seat 3. The top of the needle head is a needle point 5. The microneedle is fixed on the substrate 4 through the needle seat 3. The needle bar 2 and the needle seat 3 is a cylinder or a cone, and the microneedles are vertically fixed on the substrate 4, such as Figure 1-Figure 3 As shown, the needle head 1 is conical; or the microneedle is fixed on the substrate 4 at an inclined setting angle, and the setting angle is preferably 20-160 degrees, such as Figure 4-Figure 9 , Figure 12-Figure 14 with Figure 16-Figure 17 As shown, there is an elliptical plane parallel to the substrate 4 or inclined at a set angle at the needle head, so there is an elliptical plane needle tip 5 or the edge of the elliptical plane needle tip is further processed so that there are more sha...

Embodiment 2

[0117] Fabrication of Solid or Hollow Stainless Steel Microneedle Array Chips

[0118] Insert stainless steel solid needles or hollow needles with an outer diameter of 300 microns vertically or obliquely or penetrate the methyl methacrylate prepolymer solution with a thickness of 2 mm for the preparation of polymethyl methacrylate substrates at a set interval, The needles need to protrude from the substrate by a certain height, and after heating, polymerization and curing, the prototype of the microneedle array chip is formed. Cut off the needle bar or needle tube exposed on the bottom side of the substrate, and push the needle bar to adjust the angle between it and the substrate as needed, and finally form a Figure 1-3 , solid as shown in 10, 11 or as Figure 5 , 9 , 14, and 15 shown hollow stainless steel microneedle array chips.

Embodiment 3

[0120] Fabrication of Solid or Hollow Stainless Steel Microneedle Array Chips

[0121] A stainless steel solid rod or hollow tube with an outer diameter of 300 microns is inserted into each hole of the through-hole array mold, and then these rods or tubes are inserted or penetrated at an angle with a thickness of 2mm for the preparation of polymethacrylic acid In the methyl methacrylate prepolymer solution of the methyl ester substrate, after thermal polymerization and curing, these rods or tubes are cut off at a distance of 0.5 to 8 mm from the substrate to form a prototype of a solid rod or hollow tube array chip, such as Figure 23A shown. If hollow microneedles are to be manufactured, the tube or substrate on the bottom side of the substrate of the chip must be smoothed to ensure that all tubes are exposed on the surface of the substrate on this side; the stainless steel rod or tube on the other side can be pushed to adjust its relationship with the substrate as required ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com