Transparent PMMA composite sound barrier board and preparation method thereof

A barrier board, transparent technology, applied in the direction of noise absorption device, construction, coating, etc., can solve the problems of increasing the risk of accidents, not enough to improve the anti-corrosion properties of PMMA, affecting the transparency and appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

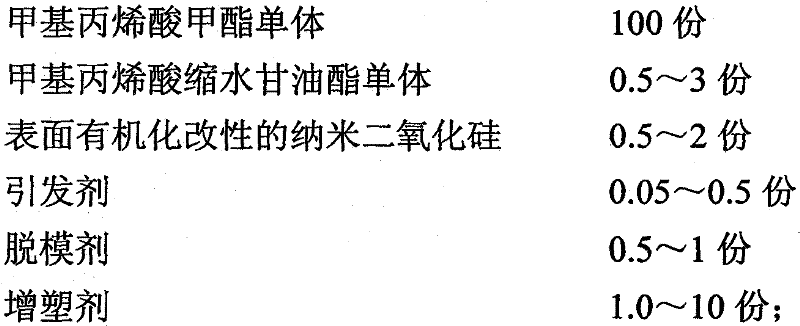

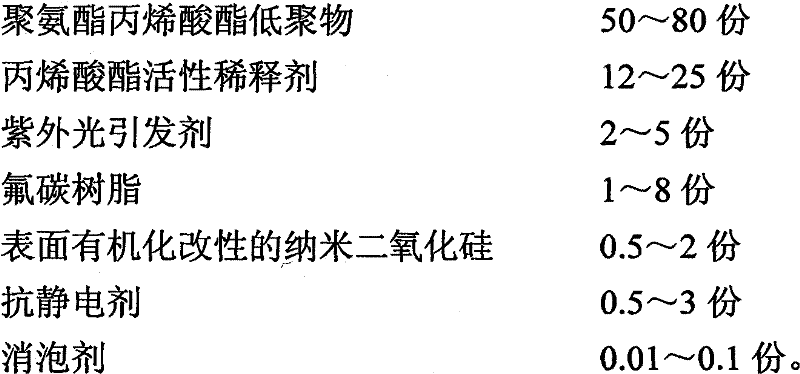

Embodiment 1

[0066] Get 2 parts by weight of nano-silica (BT386, produced by Shouguang Baote Chemical Co., Ltd., whose BET specific surface area is greater than or equal to 260m2) through silane coupling agent modification. 2 / g), added to the reaction kettle containing 100 parts by weight of methyl methacrylate monomer, stirred at high speed (1000 turns (rotor) / min) for 0.5h to mix and disperse evenly, then added 0.4 parts by weight of azobisiso Nitrile, 0.8 parts by weight of stearic acid, 4 parts by weight of dibutyl phthalate, 3 parts by weight of glycidyl methacrylate, warming up to 75 ° C, prepolymerization reaction 60min under high-speed stirring, until becoming a viscous slurry ( The viscosity is about 1.0Pa·s). Cool to 30°C, vacuum defoam the slurry, and pour it into the mold. After sealing, put the mold into a water bath, raise the temperature to 45°C, and make it polymerize for 24 hours. The mold was transferred to a drying room, and the temperature was raised to 110°C for 1.6...

Embodiment 2

[0071] Take by weighing 1.6 parts by weight of surface organically modified nano silicon dioxide (DNS-3, produced by Nanomaterials Engineering Technology Research Center of Henan Province, whose BET specific surface area is 200 ± 25m 2 / g), join in the reactor containing 100 parts by weight of methyl methacrylate monomer, stir at high speed for 0.5h to make it mix and disperse evenly, then add 0.5 parts by weight of benzoyl peroxide, 0.8 parts by weight of pentaerythritol stearic acid Esters, 2.5 parts by weight of dioctyl phthalate, 2.5 parts by weight of glycidyl methacrylate, heated up to 80°C, and pre-polymerized for 50 minutes under high-speed (1000rotor / min) stirring until it became a viscous slurry (viscosity of about 1.0 Pa·s). Cool to 35°C, vacuum defoam the slurry, and pour it into a mold with iron wires fixed at a distance of 0.2m. After sealing, put the mold into a water bath, raise the temperature to 50°C, and conduct a polymerization reaction for 20 hours. Tran...

Embodiment 3

[0076] Weigh 1.2 parts by weight of nano-silica (BT386, produced by Shouguang Baote Chemical Co., Ltd., whose BET specific surface area is greater than or equal to 260m 2 / g), join in the reactor containing 100 parts by weight of methyl methacrylate monomer, stir at high speed for 0.5h to make it mix and disperse evenly, then add 0.25 parts by weight of dilauroyl peroxide, 0.75 parts by weight of stearic acid, 5 parts by weight of tricresyl phosphate, 2 parts by weight of glycidyl methacrylate, heat up to 85°C, and pre-polymerize for 40 minutes under high-speed (1000rotor / min) stirring until it becomes a viscous slurry (viscosity is about 1.0Pa·s) . After cooling to 30°C, the slurry was subjected to vacuum defoaming treatment, and injected into a mold fixed with polyester fiber bundles at a distance of 0.1 m. After sealing, put the mold into a water bath, raise the temperature to 45°C, and conduct a polymerization reaction for 30 hours. Transfer the mold to a drying room, ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com