Environmental-friendly composite water-proof paint

A waterproof coating, environmental protection technology, applied in the direction of coating, can solve the problems of simple process, aging, and poor puncture resistance of waterproof coating, and achieve the effect of preventing ultraviolet radiation, changing molding speed, and improving stain resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

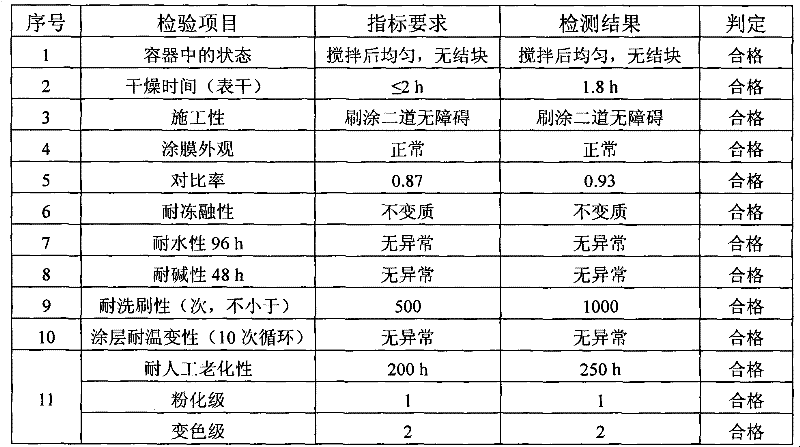

Examples

Embodiment 1

[0013] The primer is uniformly mixed with the following components: 45% sodium metasilicate with a modulus of 3 to 4, 5% triethanolamine, 7% sodium fluorosilicate, 4% short glass fiber, 20% kaolin powder, quartz powder 3%, barium sulfate 8%, mica powder 2%, sodium polycarboxylate 3%, 1,2-di-n-butylnaphthalene-6-sodium sulfonate 3%;

[0014] The top coating is made by mixing the following components evenly: 6% mica powder, 30% quartz powder, 30% white cement powder, 3% ethylene glycol, 4% propylene glycol, 7% barium sulfate, 2% talcum powder, hydroxyethyl Cellulose 3%, polyether modified polysiloxane 1%, deionized water 7%, sodium polycarboxylate 2%, HX-5440 1%, 8128 type styrene-acrylic emulsion 3%, modified polydimethylsiloxane Oxane 1%.

Embodiment 2

[0016] The primer is uniformly mixed with the following components: 35% sodium metasilicate with a modulus of 3 to 4, 6% triethanolamine, 10% sodium fluorosilicate, 5% short glass fiber, 18% kaolin powder, quartz powder 8%, barium sulfate 10%, mica powder 3%, sodium polycarboxylate 1%, 1,2-di-n-butylnaphthalene-6-sodium sulfonate 4%;

[0017] The top coating is made by mixing the following components evenly: 8% mica powder, 36% quartz powder, 15% white cement powder, 4% ethylene glycol, 6% propylene glycol, 9% barium sulfate, 8% talcum powder, hydroxyethyl Cellulose 1%, polyether modified polysiloxane 2%, deionized water 2%, sodium polycarboxylate 1%, HX-5440 2%, 8128 type styrene-acrylic emulsion 5%, modified polydimethylsiloxane Oxane 1%.

Embodiment 3

[0019] The primer is uniformly mixed with the following components: 20% sodium metasilicate with a modulus of 3 to 4, 8% triethanolamine, 4% sodium fluorosilicate, 6% short glass fiber, 15% kaolin powder, quartz powder 10%, barium sulfate 16%, mica powder 8%, sodium polycarboxylate 9%, 1,2-di-n-butylnaphthalene-6-sodium sulfonate 4%;

[0020] The top coating is made by mixing the following components evenly: 3% mica powder, 15% quartz powder, 32% white cement powder, 6% ethylene glycol, 8% propylene glycol, 4% barium sulfate, 10% talcum powder, hydroxyethyl Cellulose 2%, polyether modified polysiloxane 1%, deionized water 3%, sodium polycarboxylate 0.5%, HX-5440 0.5%, 8128 type styrene-acrylic emulsion 10%, modified polydimethylsiloxane Oxane 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com