Low-lag microcellular rubber material for oscillation reduction of high-speed railway fastener and preparation method thereof

A technology of microporous rubber and high-speed railway, which is applied in the field of fatigue-resistant, high-strength microporous rubber material and its preparation, damping backing material, and low hysteresis. Stiffness ratio, fatigue test and service life and other issues, to achieve the effect of weakening dynamic hysteresis, low dynamic and static stiffness ratio, and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

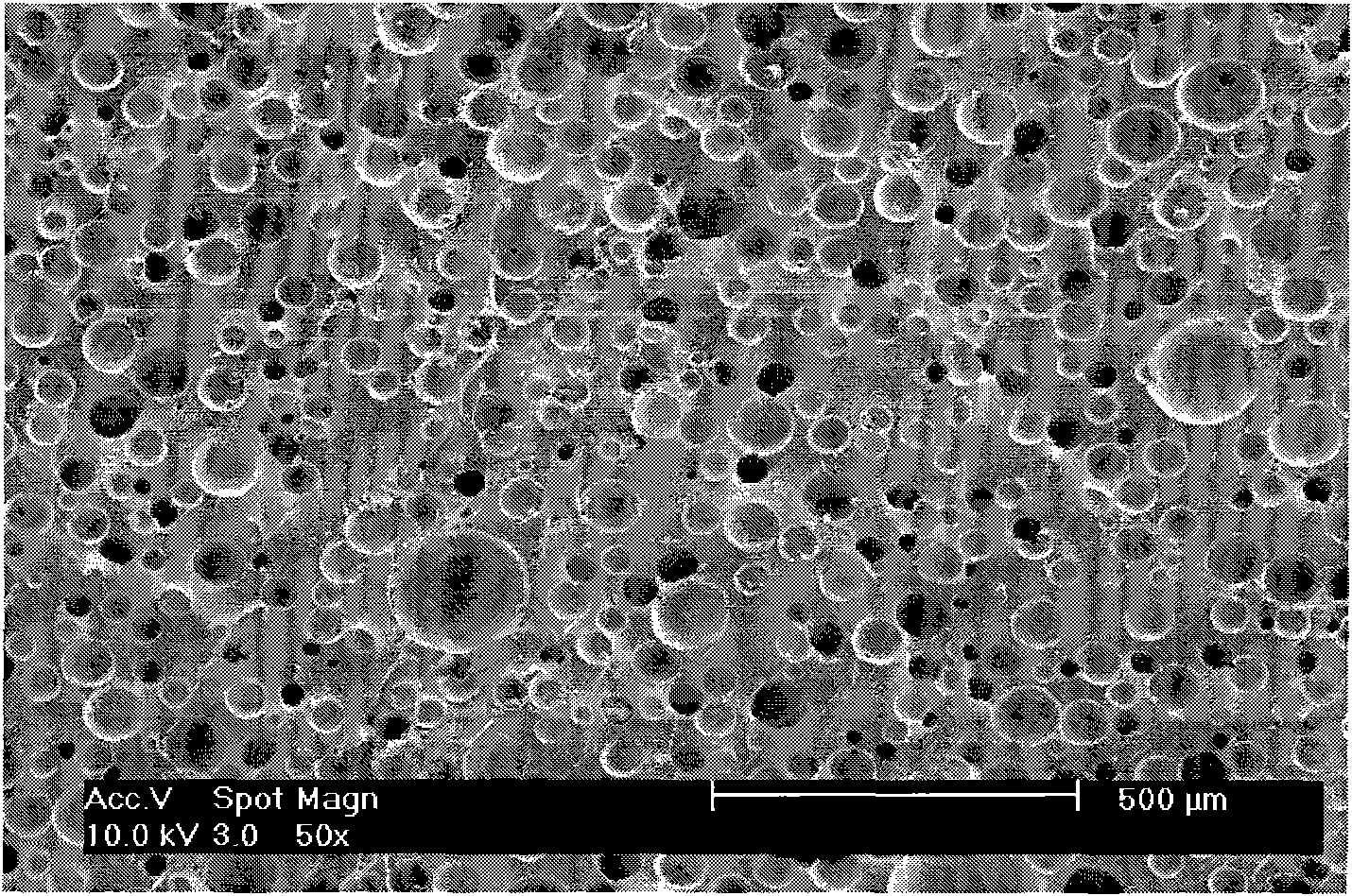

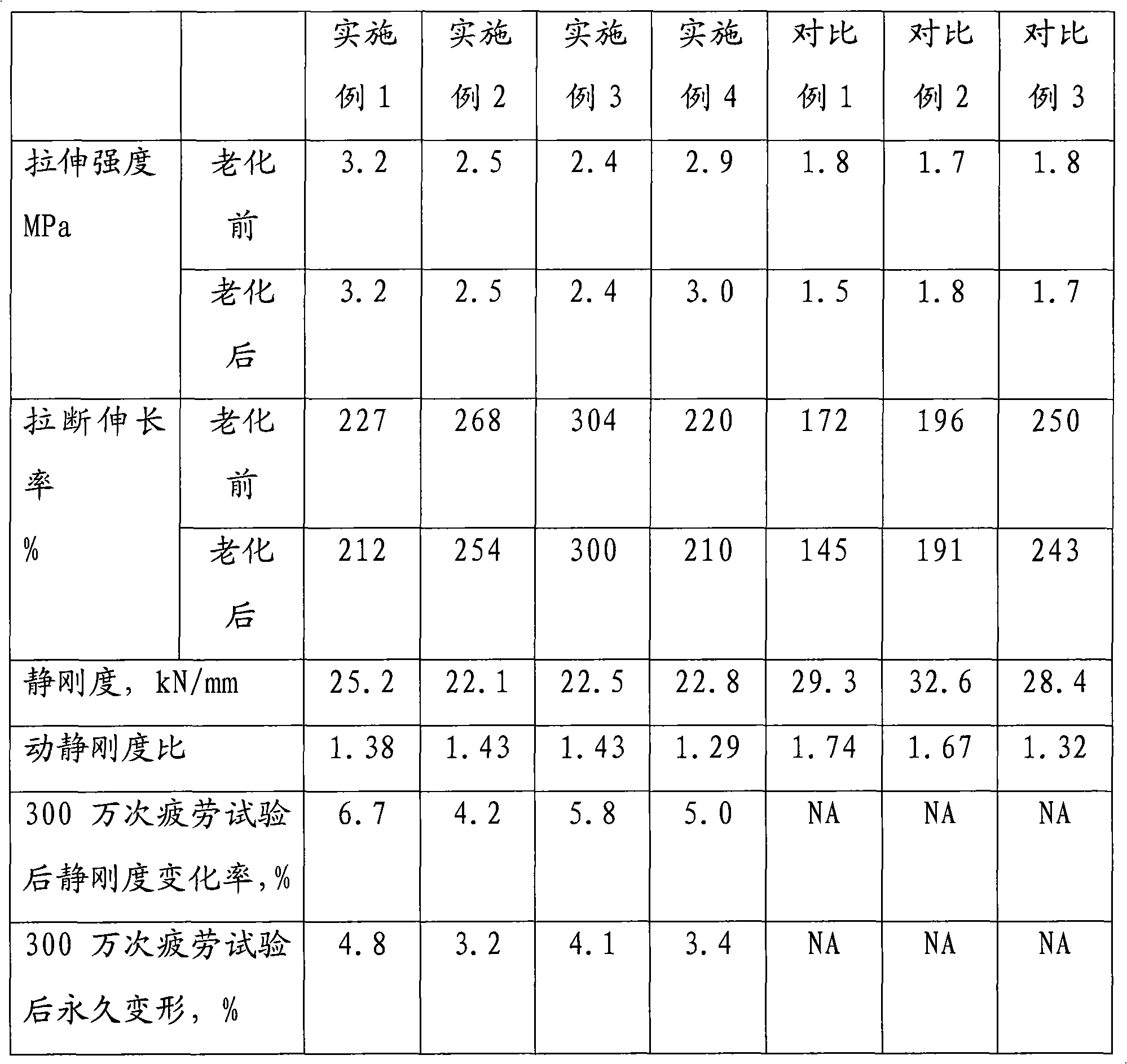

[0027] Embodiment 1: add 100kg EPDM rubber (commercially available EPDM4045) in internal mixer, masticate, then add nano silica 40kg, nano acicular silicate 30kg, nano carbon black N33010kg, silane coupling agent Si-6916kg, mixed for 30 minutes in a mixing room at 100°C, and the rotor speed was 100r / min. Take it out and put it back into another internal mixer after cooling, add 1kg of anti-RD, 4kg of foaming agent AC, 15kg of white ointment, 5kg of zinc oxide, 3kg of stearic acid, 1kg of CZ, 0.5kg of TT, and 0.5kg of DM , Double 2, 52kg, TAIC 3kg, sulfur 2kg, banburying at room temperature for 10min to get a well-mixed rubber compound.

[0028]Put it into a mold with a size of 285×160×10 (mm) for pre-vulcanization, and the process conditions are 120°C×15min×10MPa. Take it out and put it into a mold with a size of 320×180×12 (mm) for foaming and vulcanization. The process conditions are 170°C×20min×10MPa. Take it out and carry out post-processing in an oven at 150° C. for 2 h...

Embodiment 2

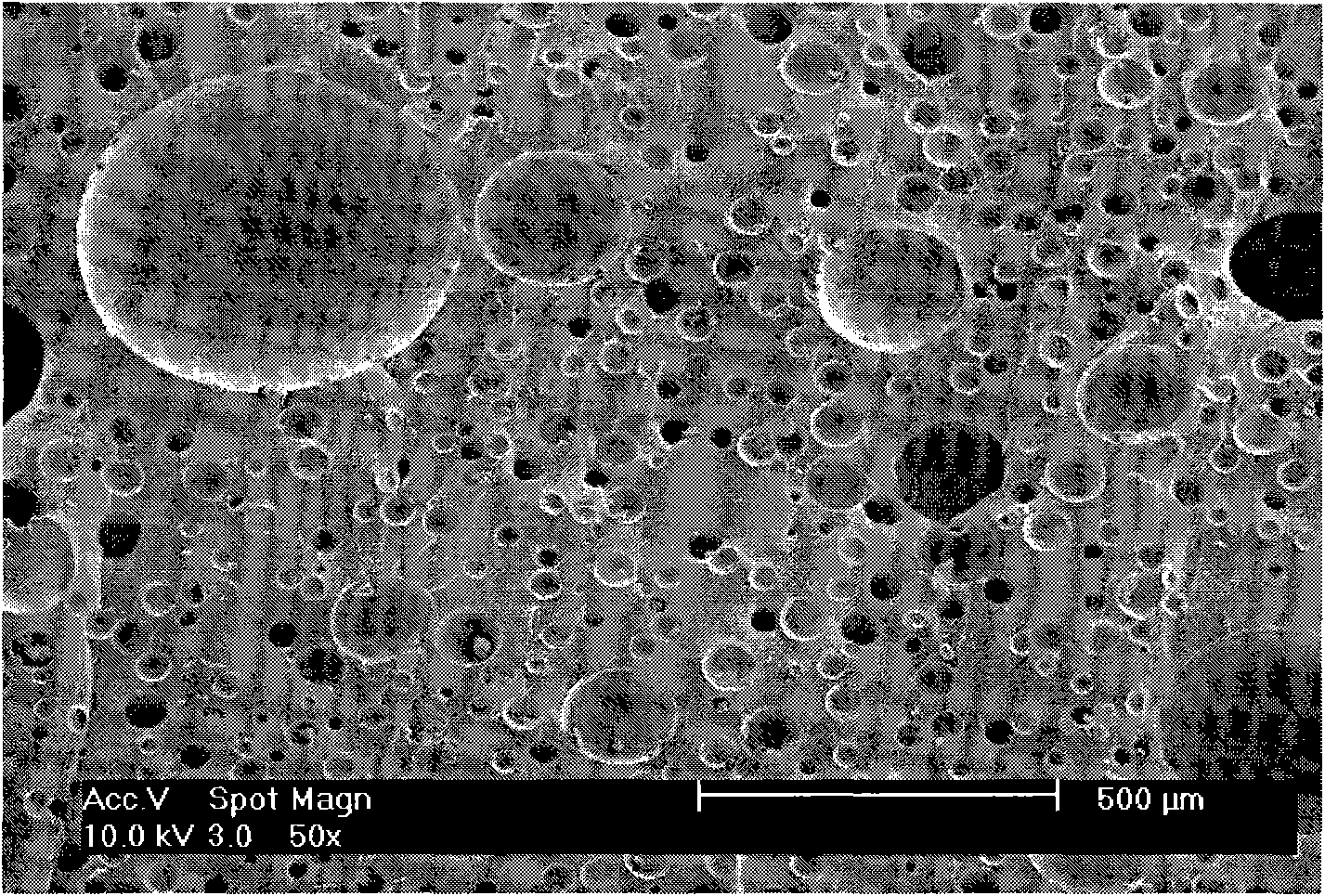

[0029] Embodiment 2: add 100kg EPDM rubber (commercially available EPDM4045) in internal mixer, masticate, then add nano silicon dioxide 20kg, acicular silicate 20kg, carbon black N33010kg, silane coupling agent Si- 69 10kg, mixed for 10 minutes in the internal mixing room at 150°C, and the rotor speed was 40r / min. Take it out and put it back into another internal mixer after cooling, add 2kg of anti-RD, 2.5kg of foaming agent AC, 8kg of white ointment, 4kg of zinc oxide, 1.5kg of stearic acid, 0.5kg of CZ, 0.5kg of TT, and 0.5kg of TT. DM 0.5kg, double 2.51kg, TAIC 1kg, sulfur 1kg, banburying at room temperature for 10min to obtain a uniformly mixed rubber compound. Pre-vulcanization, foaming, and post-vulcanization processes are the same as in Example 1. The mechanical properties, static stiffness, dynamic and static stiffness ratio of the obtained microporous EPDM rubber material before and after aging, and the static stiffness change rate and permanent deformation after 3...

Embodiment 3

[0030] Embodiment 3: add 100kg EPDM rubber (commercially available EPDM4045) in internal mixer, masticate, then add nano silicon dioxide 20kg, acicular silicate 15kg, carbon black N3305kg, silane coupling agent Si- 698kg, kneading in the internal mixing room at 130°C for 15min, the rotor speed is 60r / min. Take it out and put it back into another internal mixer after cooling, add 1.5kg of anti-RD, 2kg of foaming agent AC, 5kg of white ointment, 6kg of zinc oxide, 3kg of stearic acid, 1.2kg of CZ, 0.8kg of TT, and DM 1kg, double 2, 52.5kg, TAIC 3kg, sulfur 2.5kg, banburying at room temperature for 10 minutes to obtain a uniformly mixed rubber compound. Pre-vulcanization, foaming, and post-vulcanization processes are the same as in Example 1. The mechanical properties, static stiffness, dynamic and static stiffness ratio of the obtained microporous EPDM rubber material before and after aging, and the static stiffness change rate and permanent deformation after 3 million fatigue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com