Method for performing surface modification on polymer by using phenol derivative

A phenol derivative and surface modification technology, which is applied in the field of organic polymer surface modification, can solve the problems of inability to achieve group selectivity, wet chemical oxidation pollution, and huge investment, and achieve rapid and effective modification effects, No effect on surface morphology and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

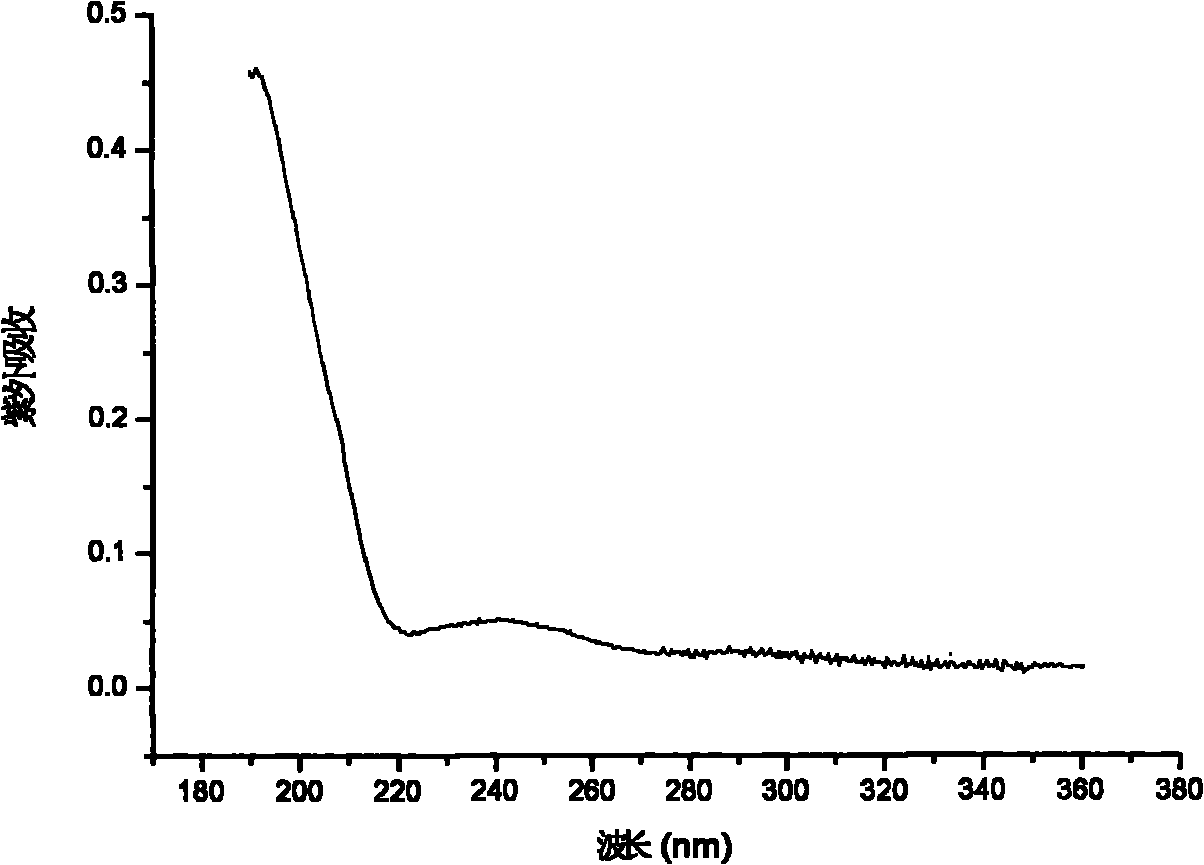

[0035] Preparation concentration is the solution of 4-hydroxyaniline in the mixed solvent of acetone and water (acetone / water=3 / 7, volume ratio) of 10wt% as reaction solution, injects this reaction solution in two pieces to be prepared with micro injector The modified BOPP (biaxially oriented polypropylene) film forms a "sandwich" structure of the reactor. The intensity of the high-pressure mercury lamp is 9500μw / cm 2 irradiated under ultraviolet light for 18 min, and then stopped the reaction. At room temperature, the modified membrane was repeatedly washed with water and acetone, and dried to obtain a clean modified membrane. The surface contact angle of the modified film is shown in Table 1, and the ultraviolet absorption spectrum is shown in the attached figure 1 .

Embodiment 2

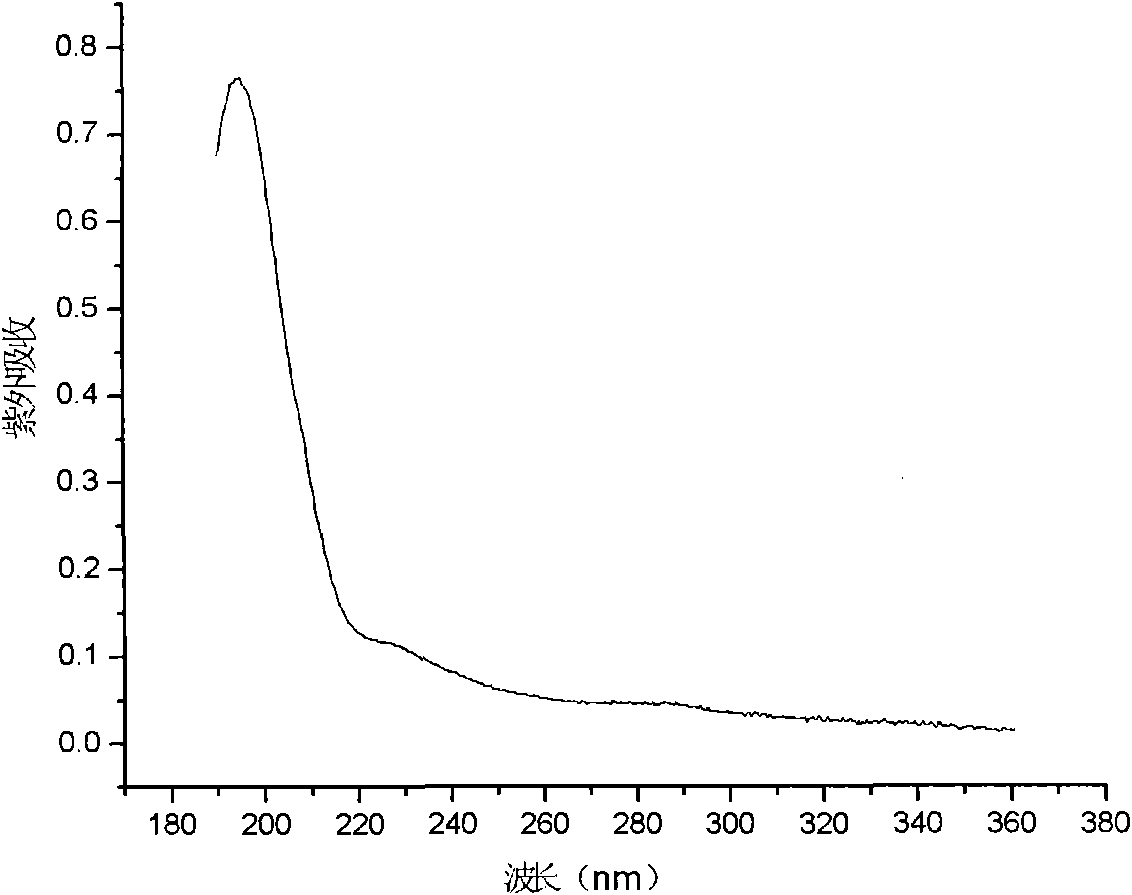

[0037] Preparation concentration is the solution of the 4-hydroxyphenethylamine of 2wt% in acetone and water (acetone / water=4 / 6, volume ratio) mixed solvent as reaction solution, this reaction solution is injected in two A reactor with a "sandwich" structure is formed between the CPP (cast polypropylene) film to be modified, and the light intensity of the medium-pressure mercury lamp is 2500μw / cm 2 Take it out after 15 minutes of ultraviolet light irradiation, and then stop the reaction. At room temperature, the modified membrane was washed with water and acetone repeatedly in turn, and a clean modified membrane was obtained after drying. The surface properties of the modified film are shown in Table 1 and the UV absorption spectrum is shown in the attached figure 2 .

Embodiment 3

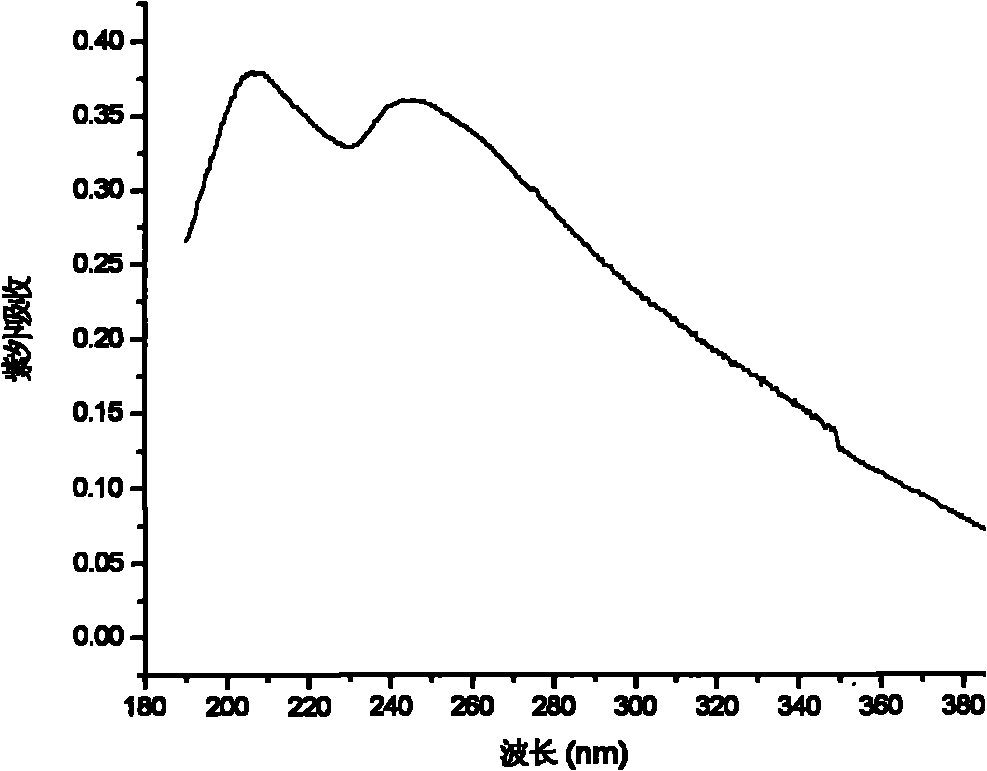

[0039] Preparation concentration is the solution of the 4-mercaptophenol of 0.1wt% in the mixed solvent of acetone and water (acetone / water=1 / 9, volume ratio) as reaction solution, injects this reaction solution in two slices with micro-injector Between the LDPE (low density polyethylene) films to be modified, a reactor with a "sandwich" structure is formed, and the intensity of the high-pressure mercury lamp is 8500μw / cm 2 Take it out after 25min of ultraviolet light irradiation, and then stop the reaction. At room temperature, the modified membrane was washed with water and acetone repeatedly in turn, and a clean modified membrane was obtained after drying. The surface properties of the modified film are shown in Table 1 and the UV absorption spectrum is shown in the attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com