Method for preparing modified polytrimethylene terephthalate

A polyterephthalic acid and propylene glycol technology, applied in the direction of single-component copolyester rayon, etc., can solve the problems of insufficient fiber crystallization, different fiber uniformity, scratches on clothing, etc., to speed up the entry into the lattice The effect of increasing the speed, improving the rapid crystallization ability, and improving the damage resistance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

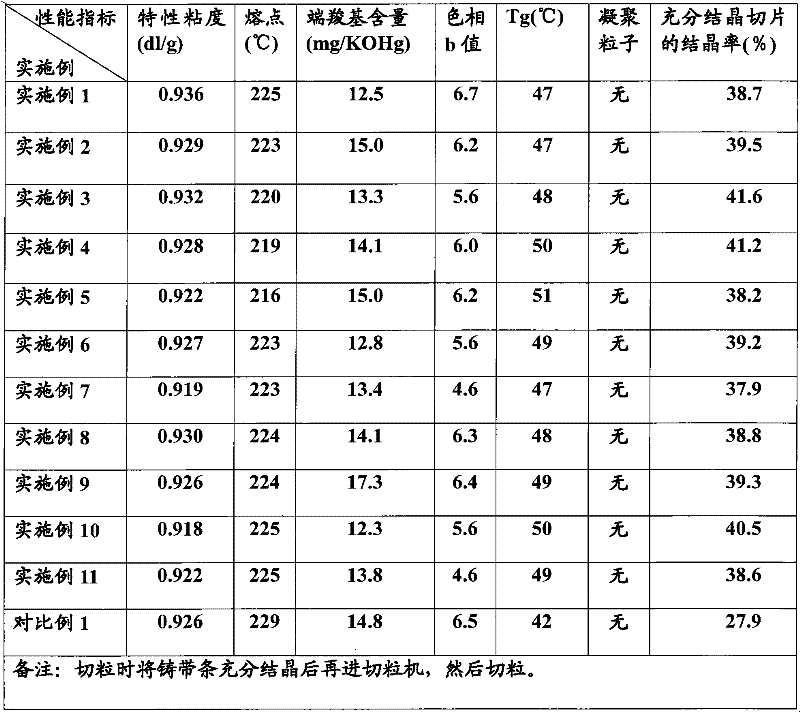

[0024] The preparation method of the PTT polyester comprises an esterification reaction process and a polymerization reaction process. According to the present invention, in addition to terephthalic acid as the first monomer of the esterification reaction and 1,3-propanediol as the second monomer, the initial reaction raw materials participating in the esterification reaction also include a third monomer. The third monomer is selected from straight-chain aliphatic dicarboxylic acids with 3 to 20 carbons, 1,4-cyclohexanedicarboxylic acid, straight-chain aliphatic diols with 4 to 20 carbons, 1,4-cyclohexane One or more combinations of hexanedimethanol, wherein: the linear aliphatic dicarboxylic acid includes but not limited to malonic acid, succinic acid, glutaric acid, adipic acid, azelaic acid and decane Diacids, etc., the linear aliphatic diols include but not limited to 1,4-butanediol, 1,5-pentanediol, 1,6-hexanediol, 1,7-nonanediol and 1, 8-decanediol, etc. According to t...

Embodiment 1

[0032] The present embodiment provides a kind of preparation method of PTT polyester chip, and it comprises the steps:

[0033] (1) Esterification reaction: Add 18kg of purified terephthalic acid (PTA) and 8.4kg of 1,3-propanediol (PDO) into a 70L polyester experimental device, add 100g of adipic acid, and add a prepared esterification catalyst Solution (containing 45ppm effective titanium, 8ppm effective tin and 10ppm zinc acetate), start to heat up and pressurize to 0.3MPa to carry out esterification reaction, the esterification temperature is controlled at 220-260°C, and return to normal pressure after the esterification is completed. end reaction;

[0034] (2) Polymerization reaction: add 1.5L PDO to the reaction system after step (1) to lower the temperature, make the temperature in the kettle drop to 220, and add 150ppm stabilizer phosphoric acid. Slowly add 200g of polyethylene glycol (PEG 400) with an average molecular weight of 400 weighed in advance, and add a titan...

Embodiment 2

[0036] The preparation method of the PTT polyester chips according to the present embodiment is basically the same as in Example 1, except that the addition of adipic acid in step (1) is 200 g; in step (2), the addition of PEG 400 is 300 g. The slice index is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com