Polyolefin functional master batch, preparation method thereof and use thereof

A functionalized, polyolefin technology, applied in the direction of conjugated synthetic polymer man-made filaments, etc., can solve the problems of spinning, film drawing processing difficulties, antibacterial delay, not resistant to washing service life, etc., to overcome easy migration The effect of poor durability, excellent processing performance, and safety performance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

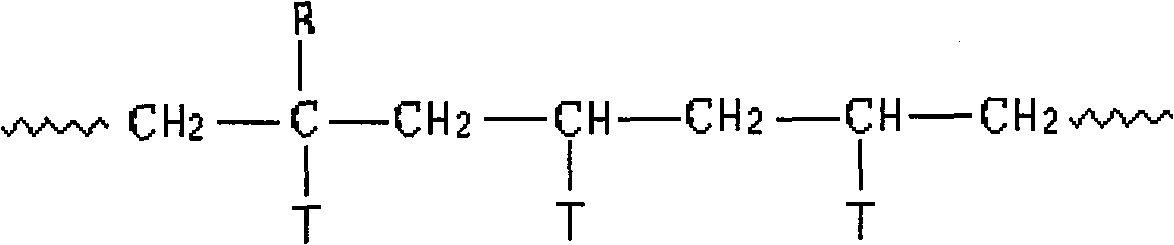

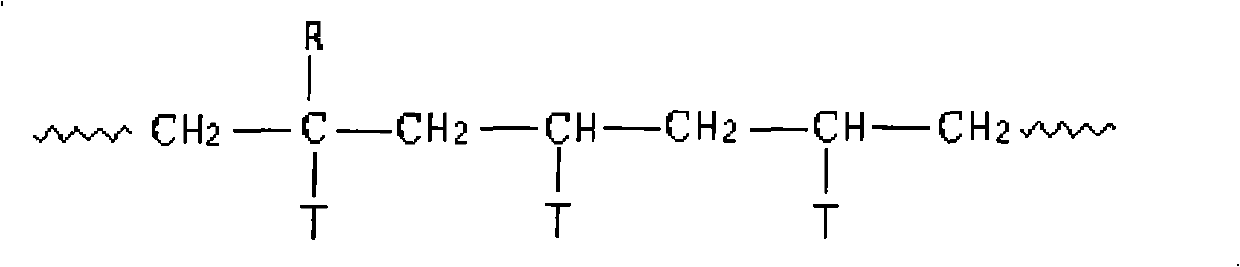

Method used

Image

Examples

Embodiment 1

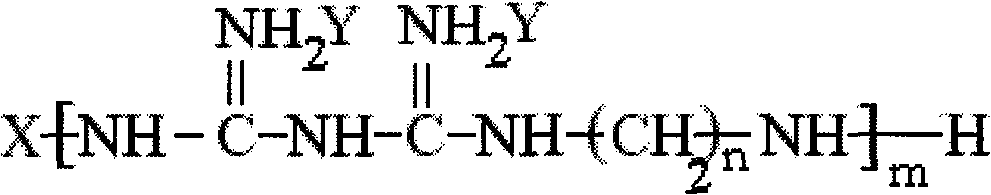

[0085] The preparation method of the maleate of polydecanediamine biguanide carbonate, the method may further comprise the steps:

[0086] Take 172g of 1,10-decanediamine, make it into a 40%wt aqueous solution, put it into a 1000ml three-necked bottle, pass in carbon dioxide until the pH value reaches 3, and then distill under reduced pressure to remove water. Under nitrogen protection, add 84g dicyandiamide, stir and heat up to 110°C, react for 1 hour, then heat up to 185°C for 8 hours, stop heating; after cooling, add water to dissolve the product, then add 35g maleic anhydride, The reaction was carried out at room temperature for 40 minutes, and finally the water was distilled off under reduced pressure, and dried for use.

[0087] The test results show that its number-average molecular weight is 3,800, its thermal decomposition temperature is 370°C, and there are characteristic absorption peaks of guanidinium, amine, amide, double bond and other groups in its infrared spec...

Embodiment 2

[0089] The preparation method of the acrylate of polydiethylene triamine phosphate biguanide salt, the method comprises the following steps:

[0090] Take 103g of diethylenetriamine, add it to a 250ml three-necked flask, add 20% phosphoric acid dropwise to pH = 2, then distill off water under reduced pressure; add 85g of dicyandiamide to the system, stir and raise the temperature under nitrogen protection Temperature was raised to 150°C for 5 hours, then the temperature was raised to 210°C for 8 hours, and 20 g of butyl acrylate was added, and the reaction was terminated after 100 minutes.

[0091] The test results show that its number average molecular weight is 18,000, its thermal decomposition temperature is 366°C, and there are characteristic absorption peaks of guanidinium, amine, amide, double bond and other groups in its infrared spectrum.

Embodiment 3

[0093] The preparation method of the methacrylate of polyhexamethylenediamine hydrochloride biguanide, the method comprises the following steps:

[0094] Take 116g of hexamethylenediamine, add it to a 500ml three-necked bottle, add 20% hydrochloric acid dropwise to pH=3, then distill it under reduced pressure to remove water; add 85g of dicyandiamide to the system, stir and heat up to React at 100°C for 2 hours, then raise the temperature to 160°C and react for 1 hour, then add 10g of glycidyl methacrylate, and finish the reaction after 20 minutes.

[0095] The test results show that its number-average molecular weight is 900, its thermal decomposition temperature is 365°C, and there are characteristic absorption peaks of guanidinium, amine, double bond and other groups in its infrared spectrum.

[0096] The following are the preparation examples of polyolefin functional masterbatch:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com