Use of a substrate coating for decreasing leakage of matter

A technology of coatings, substances, applied in the new application field of surface coatings to achieve improved antimicrobial effect and reduce leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0193] Prevent latex Foley catheters from leaking allergens.

[0194] For comparison, coated and uncoated Foley catheters of the same type and latex material were provided. Also, a different type of Foley catheter made of latex without any protein is provided as a reference.

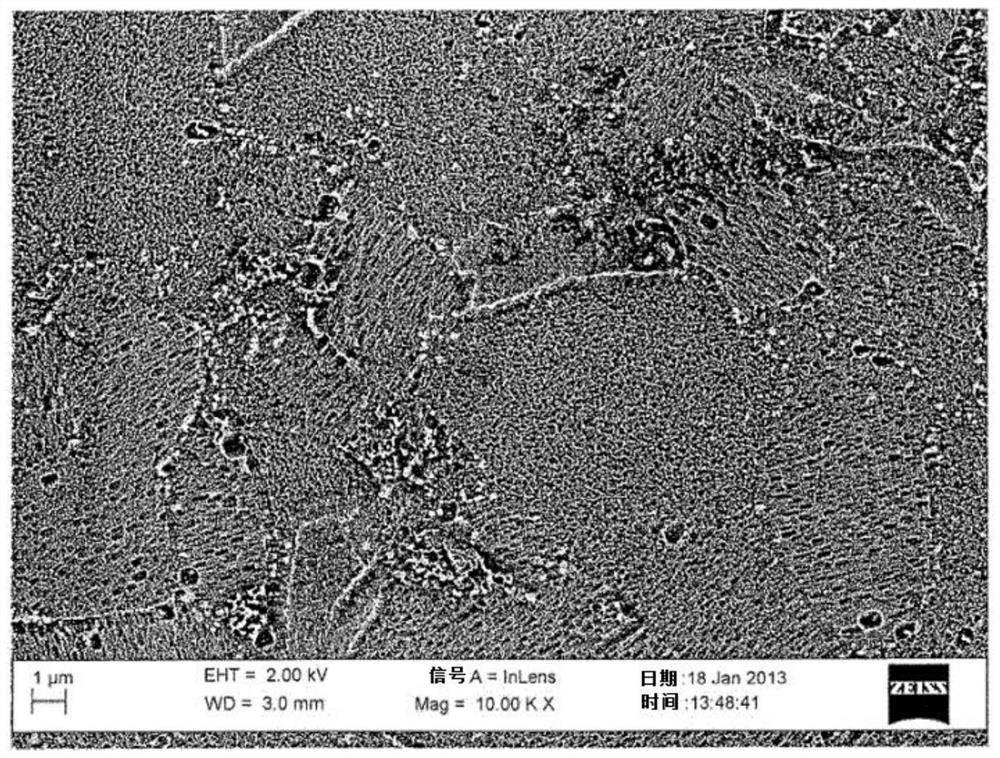

[0195] Foley latex catheters to be coated were coated as follows: A layer of silver was deposited on Foley catheters as a substrate according to the following method. First, wash and rinse the Foley catheter in deionized water. The surface of the Foley catheter was activated by immersion in an aqueous stannous chloride solution, followed by rinsing in deionized water. The surface of the Foley catheter was then plated with silver by immersing it in 3 deposition solutions containing silver ions. The resulting silver surface was applied in an amount of 0.9 μg / cm 2 . Particles consisting of 60% by weight palladium and 40% by weight gold were then deposited on the first silver surface by immersion in a d...

Embodiment 2

[0203] Leakage of ions in titanium-nickel alloys and their corrosion resistance.

[0204] Nitinol, or nitinol, is composed of approximately equal parts titanium and nickel. A study was carried out to evaluate the corrosion resistance of nickel-titanium alloys coated according to the invention compared to untreated samples. Comparisons were made on samples shaped as tubes and sheets. The coating is produced by a process that provides a thin surface layer composed of the precious metals gold, palladium and silver.

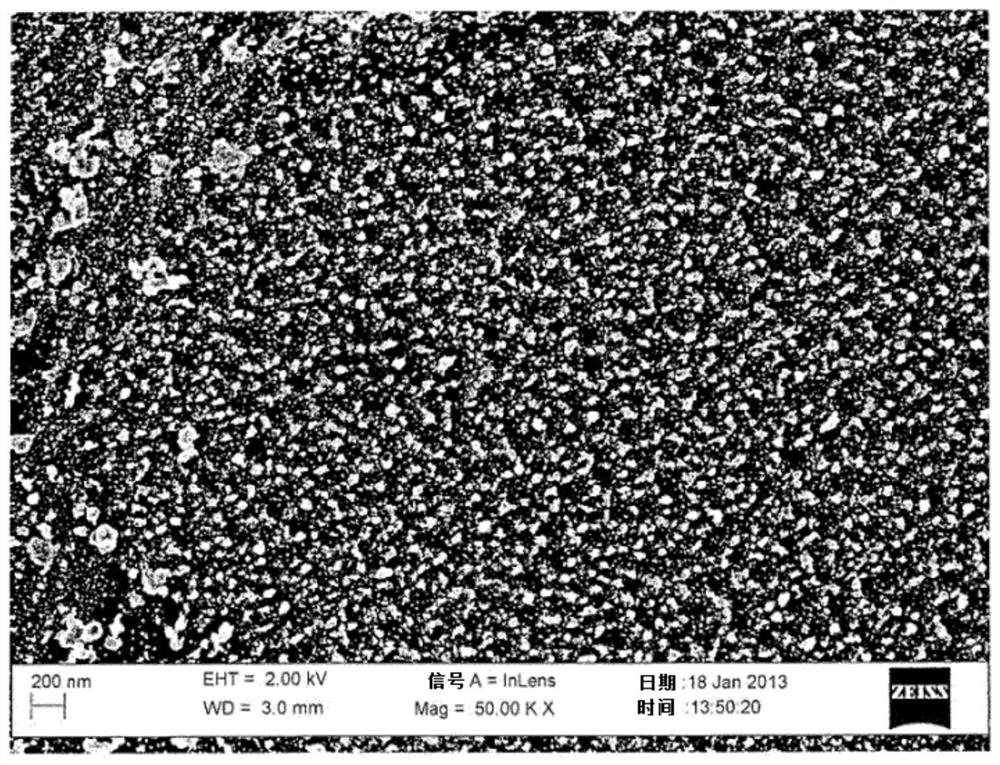

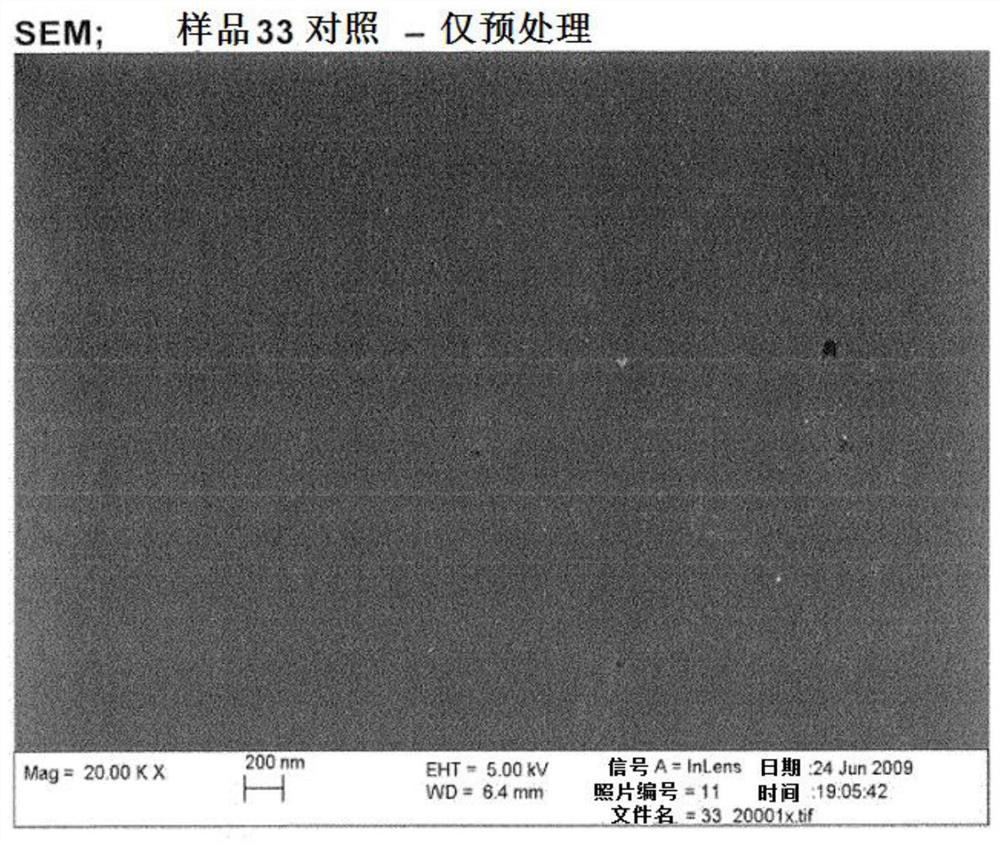

[0205] First, nickel titanium (Nitinol) tubes / sheets were cleaned with deionized water and then rinsed. Activate the surface of the tube / piece by immersing in an aqueous stannous chloride solution, followed by rinsing in deionized water. The surface of the tube / sheet is then plated with a layer of silver by immersion in 3 deposition solutions containing silver ions. The silver surface thus produced was applied in an amount of 1.6 μg / cm 2 . A particle deposition...

Embodiment 3

[0213] Reduces bacterial growth on coated Nitinol.

[0214] Nickel titanium (Nitinol) was coated using the same method as in Example 2 with the same amount of Ag and metal ratio in the particles. Microbial adhesion of Staphylococcus aureus (S. aureus) was measured for uncoated control samples and coated samples.

[0215] 2560 CFU / cm for uncoated samples 2 , for coated samples, 285CFU / cm 2 . A reduction of about 88%. This demonstrates the ability of the coating to reduce the adhesion of microorganisms to the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com