Bridging fibril welding set for digital electronic detonator

A digital electronic detonator and welding device technology, which is applied in the field of detonator manufacturing and pyrotechnics manufacturing, can solve the problems of gunpowder explosion and the limitation of the use range of ordinary detonators, so as to increase the contact area, improve the resistance to electrochemical corrosion, and improve the welding performance. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

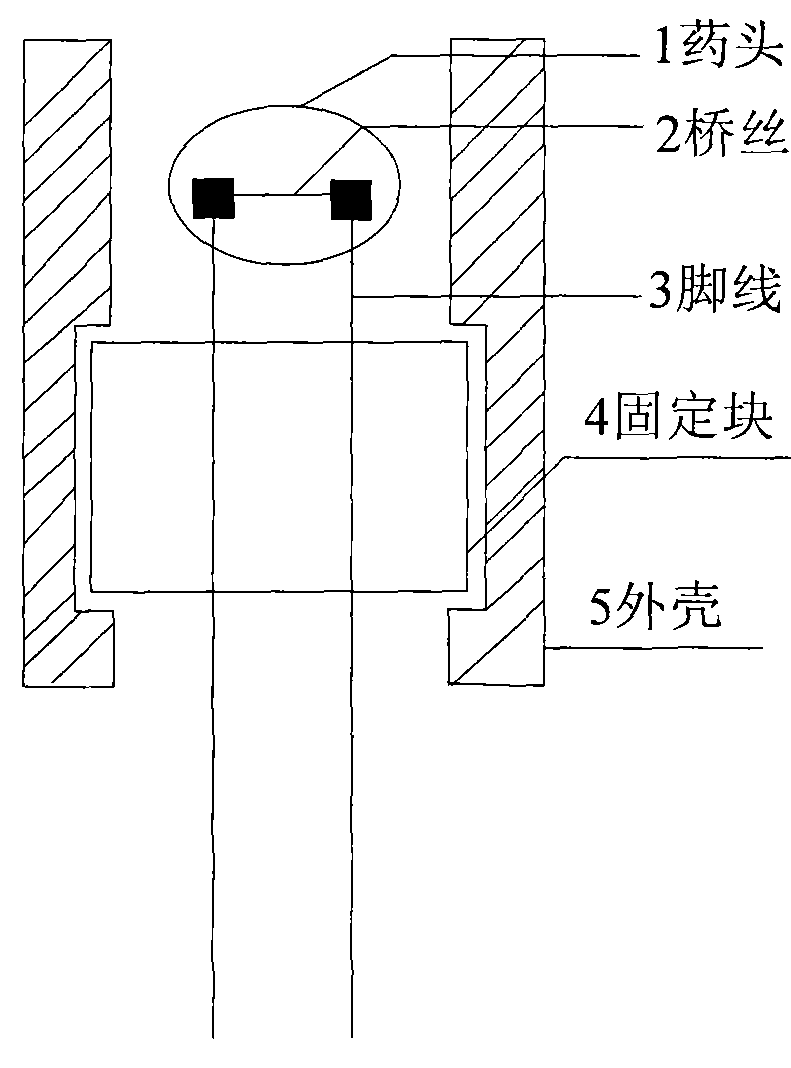

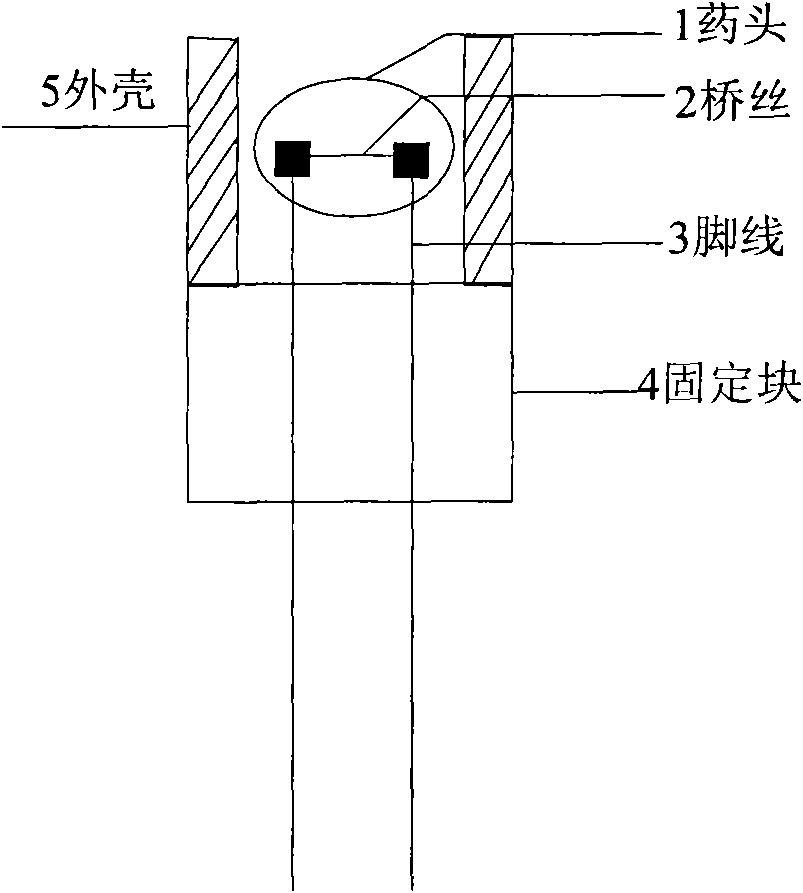

[0014] As shown in Figure 1, the bridge wire welding device for digital detonators consists of two metal legs 3, a charge 1, a fixed block 4 and a casing 5. The charge 1 includes a bridge wire 2 and gunpowder coated on the bridge wire; two The metal leg wire 3 is located in the housing 5 and extends to the outside of the housing 5, one end of the two metal leg wires 3 located in the housing 5 is used for welding the bridge wire 2, and the two metal leg wires 3 are used to extend to one end outside the housing 5 Used to connect the ignition circuit of the digital electronic detonator; the two metal legs 2 are sheet-shaped at both ends; the fixing block 4 is located in the housing 5 for fixing the two metal legs 3; the shape of the fixing block 4 is rounded Cube; the inner wall of the housing 5 has a groove that matches the shape of the fixed block.

[0015] As shown in Figure 1, the two metal legs 3 are in a sheet shape, and the width between the two metal legs is 2.6 mm to 2.9 mm...

Embodiment 2

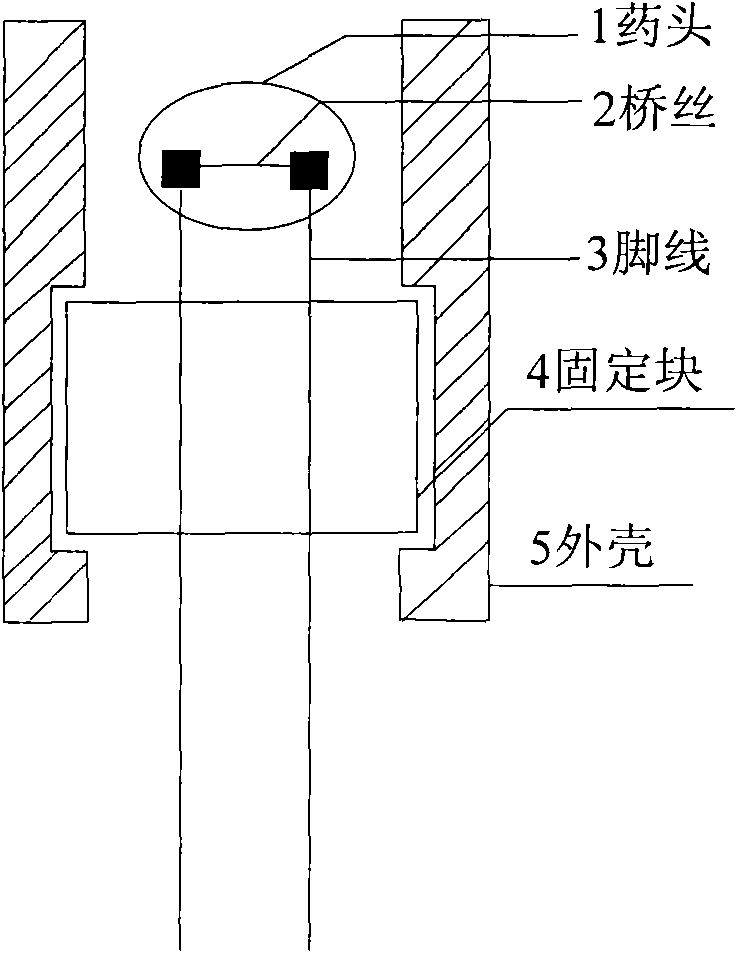

[0022] In FIG. 2, the difference between this embodiment and the embodiment is that the shell does not surround the fixed block, but is connected to the metal leg of the welding bridge wire, and the other is the same as in FIG. 1.

[0023] In summary, the bridge wire welding device for digital electronic detonators provided by the embodiment of the present invention fixes the legs of the detonator in a fixed block, and there is a gap between the two legs in the fixed block, so that the two corners The lines are arranged in parallel to solve the problem that two lines are prone to short circuit.

[0024] Compared with the prior art, the present invention increases the contact area by adopting a sheet structure where the bridge wire is welded at the end of the leg, which can greatly improve the welding quality of the bridge wire joint, simplify the production process and reduce the process cost, which is beneficial to Improve the electrochemical corrosion resistance of the bridge wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com