Method for preparing organic-inorganic compound mesoporous film and application thereof

A composite mesoporous membrane and inorganic technology, applied in the field of membrane materials, can solve the problems of low temperature resistance, long time-consuming, slow speed, etc., and achieve the effect of maintaining integrity, fast synthesis speed, and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

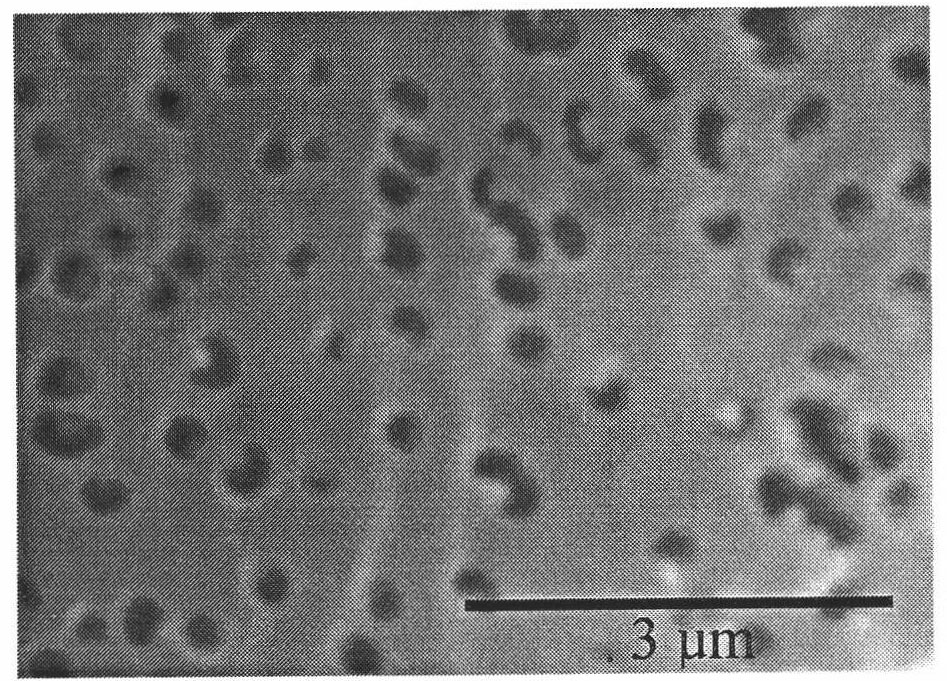

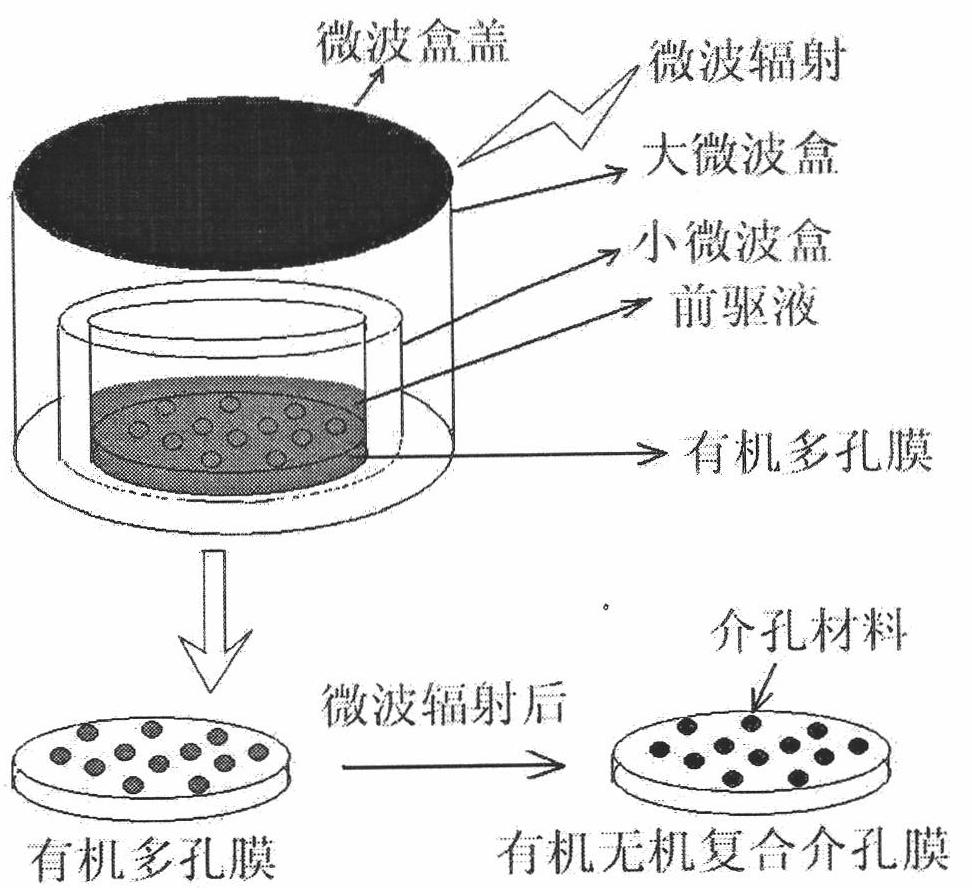

[0036] Preparation of organic-inorganic composite mesoporous membrane assembled with mesoporous materials with a pore diameter of 3.0 nm

[0037]Mix 7.68g of absolute ethanol, 11.57g of tetraethyl orthosilicate and 1ml of hydrochloric acid (2.8mmol / L), stir slowly and evenly, condense and reflux for 90min in a water bath at 60°C; then add 15g of absolute ethanol, 1.52 g cetyltrimethylammonium bromide (CTAB), 4ml of hydrochloric acid (55mmol / L) after the mixed solution, stirring reaction at room temperature 25 ℃ for 30min, cooled to room temperature 25 ℃ to obtain the precursor containing CTAB liquid. Get the precursor solution 2ml that contains CTAB obtained in the above steps, fill it in a 50ml polypropylene microwave box (diameter 50mm), then take a piece of organic porous membrane and place it in the precursor solution in the microwave box, place the uncapped The 50ml polypropylene microwave box containing the membrane and the precursor solution is placed in another empty ...

Embodiment 2

[0045] Preparation of organic-inorganic composite mesoporous membrane assembled with mesoporous materials with a pore diameter of 6.0 nm

[0046] 15g of absolute ethanol, 0.10g of hydrochloric acid (12mol / L) and 2.0g of deionized water were mixed uniformly and placed in a three-necked flask, then, under slow stirring, 1.0g of surfactant P123 was added to the mixed solution until P123 was completely dissolved, and the three-necked flask containing the mixed solution was placed in an oil bath, and at a temperature of 60°C, after slowly stirring for 1 h, 2.13 g of tetraethyl orthosilicate was gradually added dropwise, and at 60 ℃ oil bath temperature for 12h with stirring and aging, and then cooled to room temperature to obtain the precursor solution containing P123. Take the precursor solution containing P123 obtained above and put it in four 50ml polypropylene microwave boxes (diameter 50mm). In the precursor solution in the box, and the microwave box is not covered, the above...

Embodiment 3

[0053] Three pieces of SBA-15 organic-inorganic composite mesoporous membranes (0.0477g) were placed in 10ml, 0.04mg / ml myoglobinase in 0.1mol / L phosphate buffer solution (pH: 6.80) and shaken, and measured by ultraviolet-visible spectrophotometry The change of the absorbance of the myoglobinase solution soaked with the organic-inorganic composite mesoporous membrane at 408nm (the maximum visible absorption peak of the myoglobinase) with the soaking time was detected by the method. The adsorption of mesoporous membranes is directly related.

[0054] Can observe that the absorbance of myoglobinase solution at 408nm place (the visible maximum absorption peak of myoglobinase) gradually increases along with the increase of SBA-15 type organic-inorganic composite mesoporous membrane soaking time in myoglobinase solution by accompanying drawing 8 Decrease, and reach stability after 80 minutes, indicating that the mesoporous material can adsorb biomacromolecules with a molecular size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com