Grease used for metal fastener

A technology for metal fasteners and grease, applied in the field of grease, can solve the problems to be further improved, and achieve the effects of prolonging the anti-corrosion and anti-rust period, excellent sealing and improving the anti-rust performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

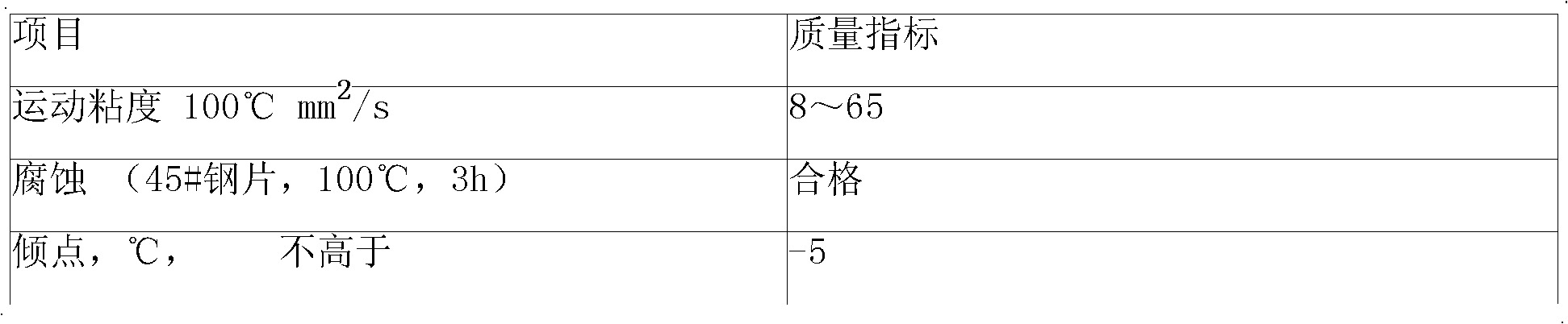

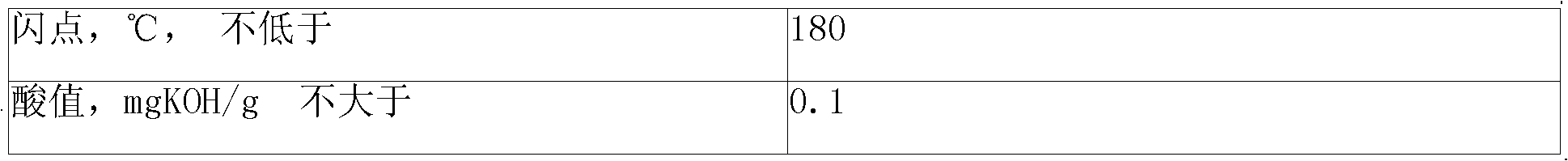

[0042] In this embodiment, the weight percent content of each component of base grease, film-forming agent, anti-oxidant anticorrosion agent, rust preventive agent and solid filler is shown in Table 2, wherein:

[0043] The base fat is saponified from the following raw materials: 8.5wt% lauryl hydroxystearic acid, 2.5wt% stearic acid, 2.5wt% lithium hydroxide monohydrate, and the balance is base oil;

[0044] The film forming agent is composed of 10 parts of ethylene propylene copolymer and 0.6 parts of epoxy resin E44;

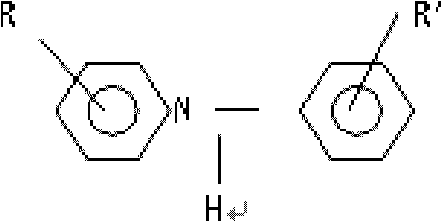

[0045] The anti-oxidation and anti-corrosion component agent is octyl / butyl diphenylamine;

[0046] The antirust agent is composed of 4.5 parts of barium petroleum sulfonate (T701), 0.5 parts of lanolin magnesium soap, and 0.1 part of benzotriazole (T706);

[0047] The solid filler consists of 5.0 parts of mica powder, 10.0 parts of talc powder, and 1.0 part of glass microspheres;

[0048] The ointment of this embodiment has a beige bright and uniform appea...

Embodiment 2

[0050] In this embodiment, the weight percent content of each component of base grease, film-forming agent, anti-oxidant anticorrosion agent, rust preventive agent and solid filler is shown in Table 2, wherein:

[0051] The base grease is formed by saponification reaction of the following raw materials: 7.0 wt% lauryl hydroxystearic acid, 4.0 wt% stearic acid, 2.5 wt% lithium hydroxide monohydrate, and base oil as the balance.

[0052] The film forming agent is composed of 15 parts of ethylene propylene copolymer and 2 parts of epoxy resin E44;

[0053] The anti-oxidation and anti-corrosion component is octyl / butyl diphenylamine;

[0054] The antirust agent is composed of 4.5 parts of barium dinonylnaphthalenesulfonate (T705), 2.0 parts of lanolin magnesium soap, and 0.1 part of benzotriazole (T706);

[0055] The solid filler consists of 10.0 parts of mica powder, 15.0 parts of light calcium carbonate, and 1.0 part of glass microspheres;

[0056] The ointment of this embodim...

Embodiment 3

[0058] In this embodiment, the weight percent content of each component of base grease, film-forming agent, anti-oxidant anticorrosion agent, rust preventive agent and solid filler is shown in Table 2, wherein:

[0059] The base grease is formed by the saponification reaction of the following raw materials: 9.0wt% lauryl hydroxystearic acid, 3.5wt% stearic acid, 1.6wt% lithium hydroxide monohydrate, 0.4wt% lime powder, and base oil as the balance;

[0060] The film forming agent is composed of 10.0 parts of ethylene propylene copolymer and 2.0 parts of polyisobutylene;

[0061] The antioxidant preservative is octyl / butyl diphenylamine;

[0062] The antirust agent is composed of 4.5 parts of barium dinonylnaphthalenesulfonate (T705), 0.5 parts of lanolin magnesium soap, and 0.1 part of benzotriazole (T706);

[0063] The solid filler consists of 5.0 parts of mica powder, 10.0 parts of talc powder, and 1.0 part of plastic microspheres.

[0064] The ointment of this embodiment h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com