Metal-based yaw brake block for wind-powdered generator and manufacture method thereof

A technology for wind turbines and brake pads, applied in the field of brake pads, can solve problems such as strategic decision-making that does not conform to national sustainable development, lack of resources, etc., and achieve the effects of improving friction stability, improving mechanical properties, and reducing wear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

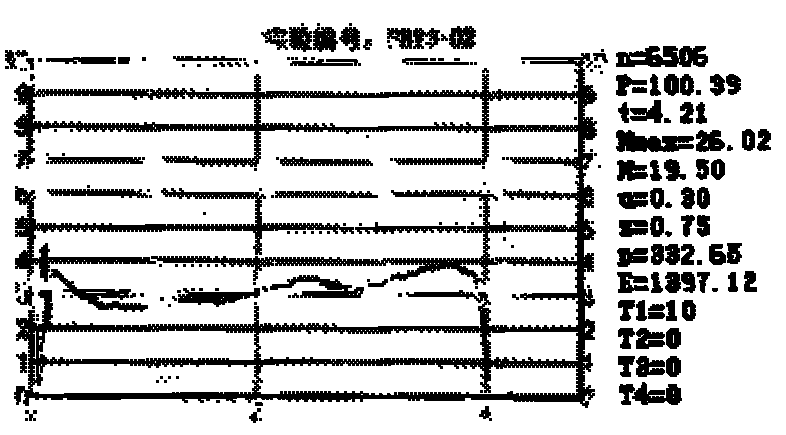

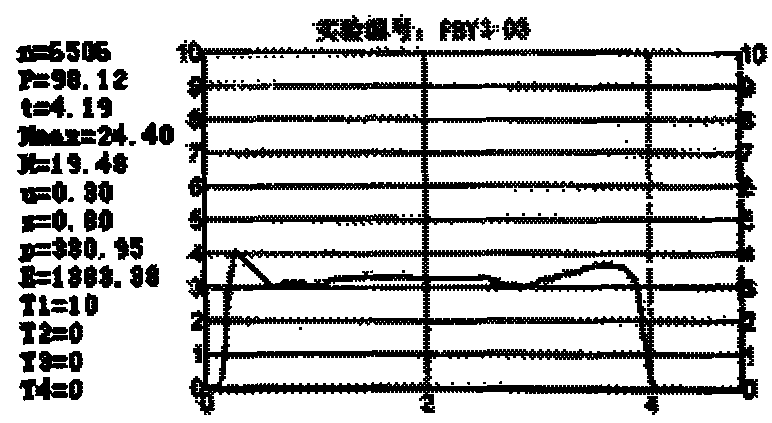

Image

Examples

Embodiment 1

[0036] The formula description of wind power generator yaw brake pad provided by the invention

[0037] Copper powder 20 (wt.%), particle size ≤70μm, copper powder purity ≥98%,

[0038] Tin powder 2 (wt.%), the particle size is ≤70μm,

[0039] Iron powder 50(wt.%), particle size ≤70μm, iron powder purity ≥98.5%,

[0040] Chopped steel fiber 6 (wt.%), its length is 2~5mm, and its diameter is 50~150μm,

[0041] Brass fiber 5 (wt.%), its length is 2.5~3.5mm, and diameter is 100~200μm,

[0042] High alumina ceramic fiber 3 (wt.%), its length is 0.5~1.5mm, and its diameter is 50~100μm,

[0043] Sulfur 1 (wt.%), the particle size of which is ≤200μm;

[0044] Aluminum oxide 2 (wt.%), the particle size of which is 70 μm to 200 μm;

[0045] Silica 3 (wt.%), the particle size of which is 70 μm to 200 μm;

[0046] Flake graphite 8 (wt.%), fixed carbon content ≥ 90%, ash content ≤ 10%, and particle size ≤ 70 μm.

[0047] In this formula system, the friction material uses iron and c...

Embodiment 2

[0055] The formula description of wind power generator yaw brake pad provided by the invention

[0056] Copper powder and tin powder 40%, the particle size is ≤70μm, copper powder purity ≥98%, wherein copper powder: tin powder = 10:1;

[0057] Iron powder 30 (wt.%), particle size ≤70μm, iron powder purity ≥98.5%,

[0058] Chopped steel fiber 5 (wt.%), its length is 2~5mm, and diameter is 50~150μm,

[0059] Brass fiber 10 (wt.%), its length is 2.5~3.5mm, and diameter is 100~200μm,

[0060] High alumina ceramic fiber 4 (wt.%), its length is 0.5~1.5mm, and its diameter is 50~100μm,

[0061] Alumina 3 (wt.%), the particle size of which is 70 μm to 200 μm;

[0062] Silica 3 (wt.%), the particle size of which is 70 μm to 200 μm;

[0063] Flake graphite 5 (wt.%), fixed carbon content ≥ 90%, ash content ≤ 10%, and particle size ≤ 70 μm.

[0064] In this formula system, the friction material uses iron and copper as the matrix, alumina and silicon dioxide as friction enhancers, tin p...

Embodiment 3

[0072] The formula description of wind power generator yaw brake pad provided by the invention

[0073] Copper powder 20 (wt.%), particle size ≤70μm, copper powder purity ≥98%,

[0074] Tin powder 2 (wt.%), the particle size is ≤70μm,

[0075] Iron powder 30 (wt.%), particle size ≤70μm, iron powder purity ≥98.5%,

[0076] Chopped steel fiber 10 (wt.%), its length is 2~5mm, and diameter is 50~150μm,

[0077] Brass fiber 5 (wt.%), its length is 2.5~3.5mm, and diameter is 100~200μm,

[0078] High alumina ceramic fiber 10 (wt.%), its length is 0.5~1.5mm, and its diameter is 50~100μm,

[0079] Sulfur 5 (wt.%), the particle size of which is ≤200 μm;

[0080] Aluminum oxide 4 (wt.%), the particle size of which is 70 μm to 200 μm;

[0081] Silica 4 (wt.%), the particle size of which is 70 μm to 200 μm;

[0082] Flake graphite 10 (wt.%), fixed carbon content ≥ 90%, ash content ≤ 10%, and particle size ≤ 70 μm.

[0083] In this formula system, the friction material uses iron and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com