Microwave preparation method of anti-oxidation coating made of carbon-based material

A carbon-based material and anti-oxidation technology, which is applied in the field of preparation of high-temperature anti-oxidation coatings for C-based materials, can solve problems such as lack of product quality, complex equipment, and high cost, and achieve reduced equipment complexity, reduced operating costs, and prevention of substrate The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

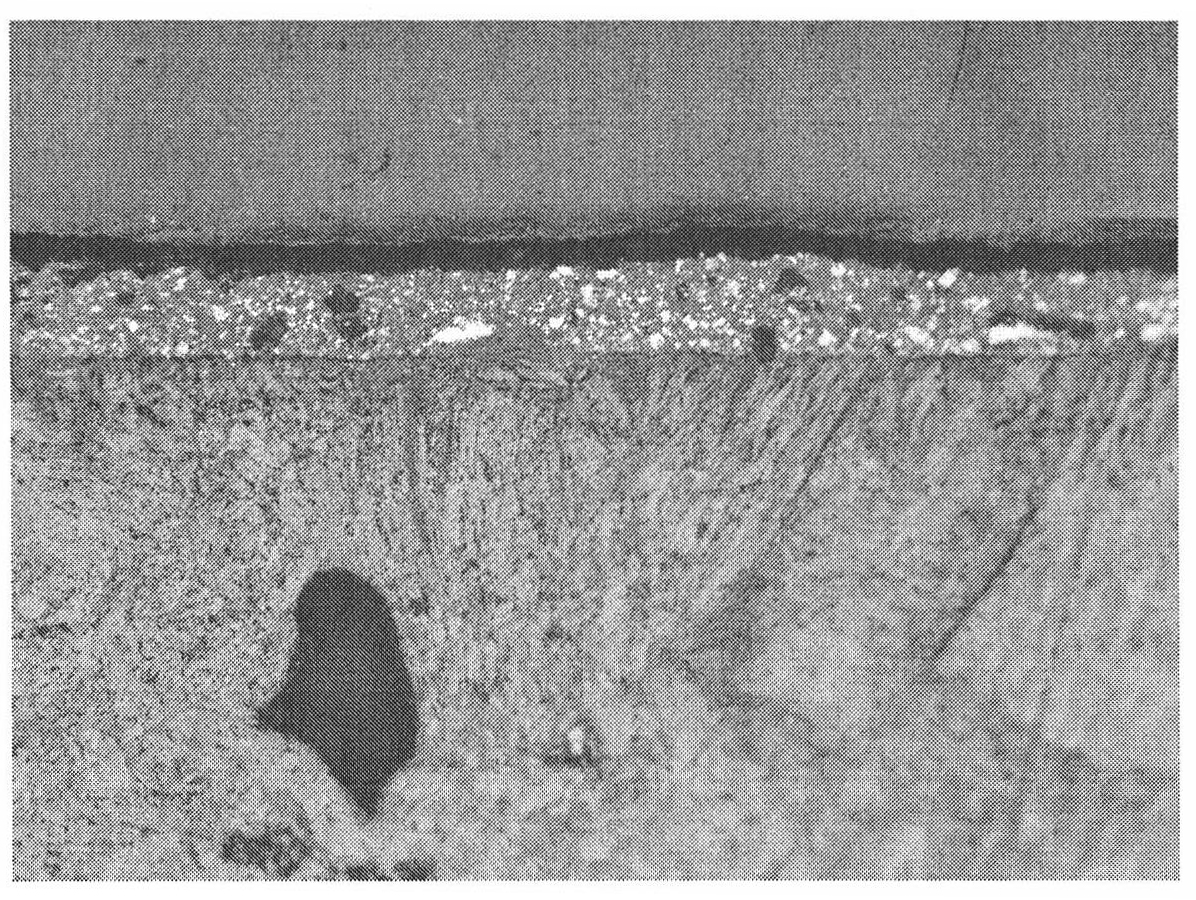

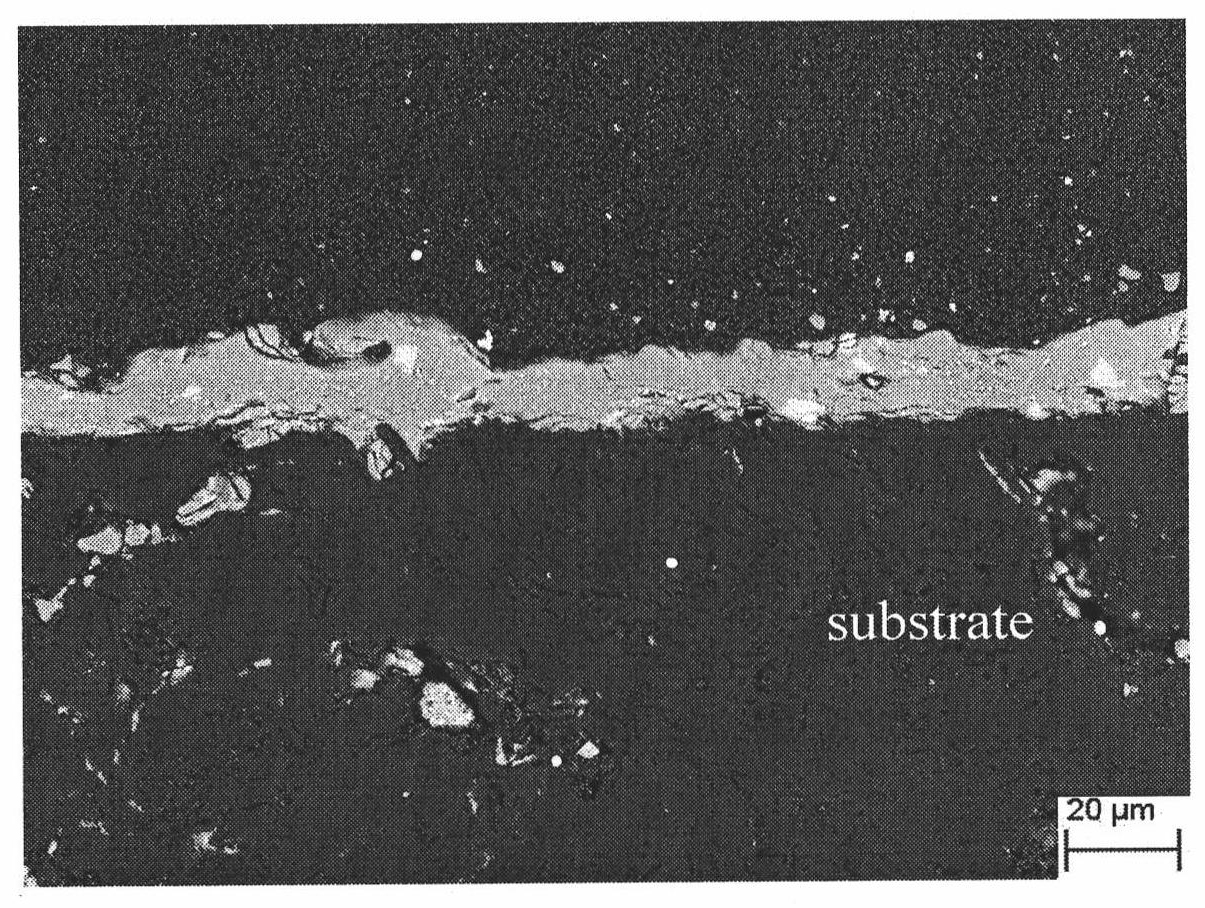

[0019] First prepare the slurry: weigh 27% of Si powder, 25% of C, and 33% of SiO 2 , 12% Al 2 o 3 powder, 2% Al aluminum powder, add 1% hydroxyethyl cellulose thickener, use absolute ethanol as a dispersant, put the above-mentioned weighed ingredients in a container for ultrasonic dispersion, not less than 10min, and then use Silica sol is used as a binder, and the addition amount of silica sol is 5% of the above slurry. The slurry is prepared by conventional paint stirring equipment, and the stirring time is 35 minutes; at the same time, the surface pretreatment process of the substrate is as follows: the carbon materials are respectively No. 600, No. 1500 and No. 2000 sandpapers were polished in turn, washed with absolute ethanol, and placed in an oven at 100°C for later use. The slurry coating process is as follows: the treated base material is dipped and coated with the prepared slurry, and dried in an oven at 100°C. The coating sintering process is as follows: put gra...

Embodiment 2

[0021] First prepare the slurry: weigh 20% of Si powder, 14% of C, and 45% of SiO 2 , 5% SiC powder, 10% Al 2 o 3 Powder, 5% Al aluminum powder, use absolute ethanol as dispersant, add 1% soluble starch thickener, the addition of silica sol is 3% of the above slurry, and adjust the slurry through conventional paint mixing equipment; matrix The surface pretreatment process is as follows: the C / C composite material is polished and polished with No. 600, No. 1500 and No. 2000 sandpaper in turn, washed with absolute ethanol, and placed in an oven at 100 ° C for use. The slurry coating process is as follows: the treated base material is dipped and coated with the prepared slurry, and dried in an oven at 100°C. The coating sintering process is as follows: put graphite powder in the alumina crucible, put the base material coated with the slurry in the crucible, then cover it completely with graphite powder, put it into a 700W microwave oven, and first adjust the power of the microw...

Embodiment 3

[0023] First prepare the slurry: weigh 12% Si powder, 20% C, and 43% SiO respectively 2 , 12% SiC powder, 5% Al 2 o 3 Powder, 8% Al aluminum powder, using absolute ethanol as a dispersant, the addition of silica sol is 8% of the above slurry, adjusted to slurry by conventional paint mixing equipment; the surface pretreatment process of the substrate is: The / SiC composite materials were respectively polished and polished with No. 600, No. 1500 and No. 2000 sandpapers in sequence, washed with absolute ethanol, and placed in an oven at 100°C for use. The slurry coating process is as follows: the treated base material is dipped and coated with the prepared slurry, and dried in an oven at 100°C. The coating sintering process is as follows: put graphite powder in the alumina crucible, put the base material coated with the slurry in the crucible, then cover it completely with graphite powder, put it into a 700W microwave oven, and first adjust the power of the microwave oven to 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com