Lithium ion battery cathode material antimony-doped lithium iron phosphate and preparation method thereof

A lithium-ion battery and lithium iron phosphate technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low tap density, poor high-rate charge and discharge performance, and wide particle size distribution, achieving reduced complexity and high production efficiency. The effect of process stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

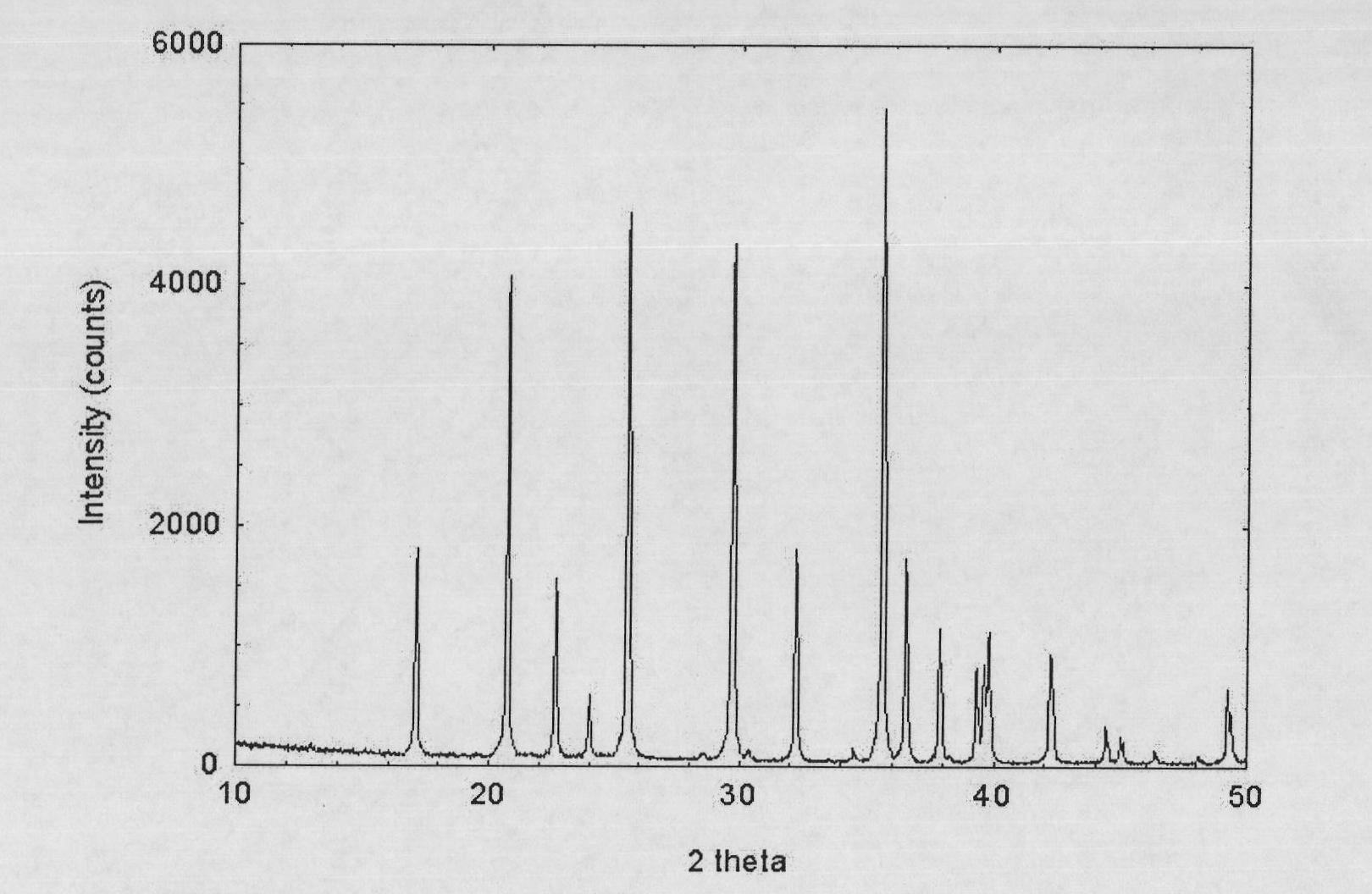

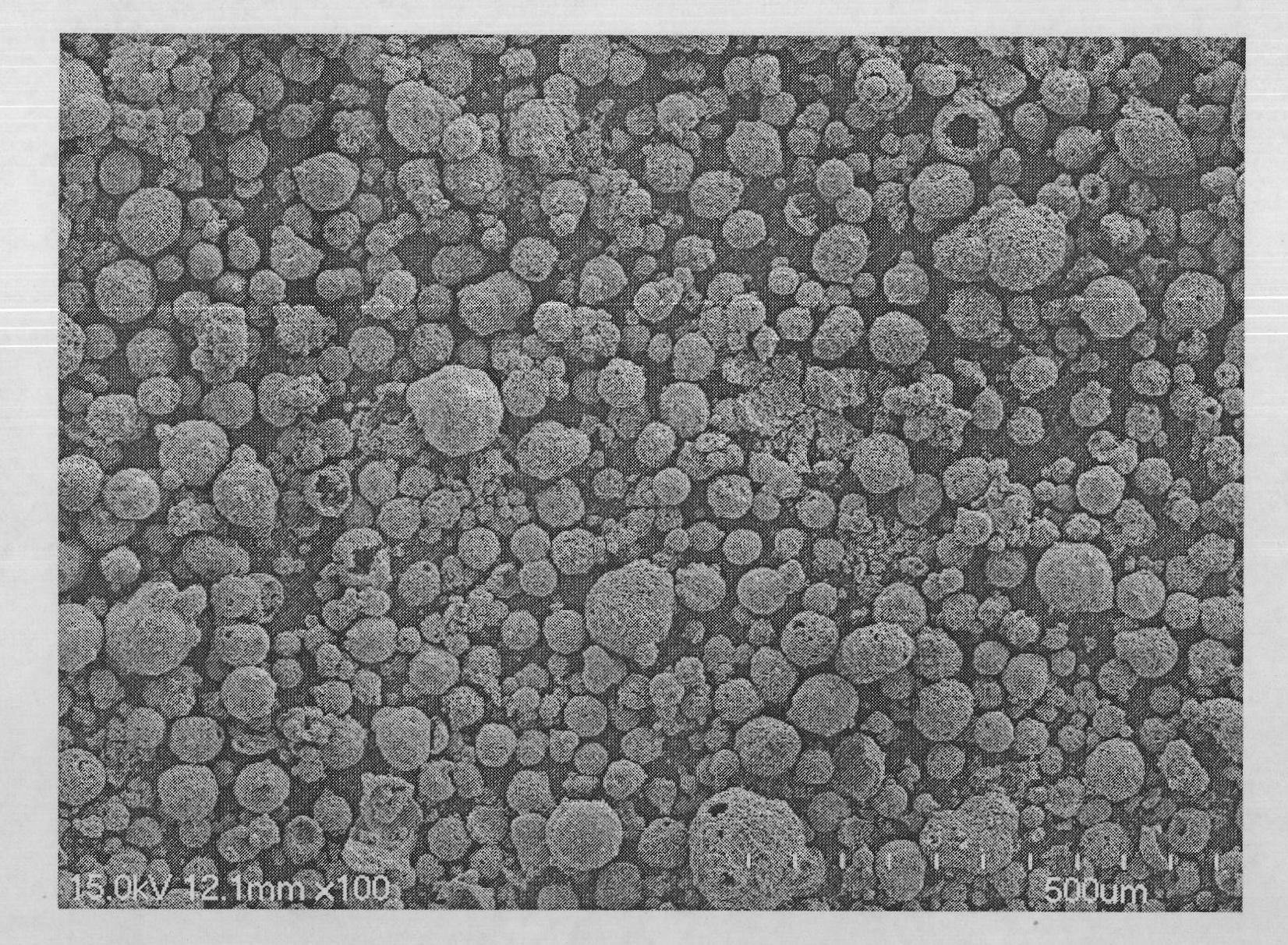

[0018] Example 1 1040g lithium dihydrogen phosphate (LiH 2 PO 4 ), 1060g iron hydroxide (Fe(OH 3 )) and 16g antimony trioxide (Sb 2 o 3 ) adding an appropriate amount of deionized water, milling for 1 to 3 hours until the particle size is 1 micron; then using a flash dryer to obtain a spherical precursor at an air inlet temperature of 300°C and an outlet air temperature of 100°C; The above precursor was pretreated at 150°C for 10h in an inert atmosphere, then heated to 700°C and kept at a constant temperature for 15h, and cooled naturally to room temperature to obtain an antimony-doped lithium iron phosphate material with the nominal molecular formula LiFe 0.99 Sb 0.01 PO 4 . The XRD pattern of the product is shown in figure 1 As shown in , the material has an average particle size of 15 μm and a tap density of 1.4 g / cm 3 .

[0019] Reduce iron hydroxide (Fe(OH 3 )) and increasing antimony trioxide (Sb 2 o 3 ) amount, then the corresponding LiFe 0.93 Sb 0.07 PO ...

Embodiment 2

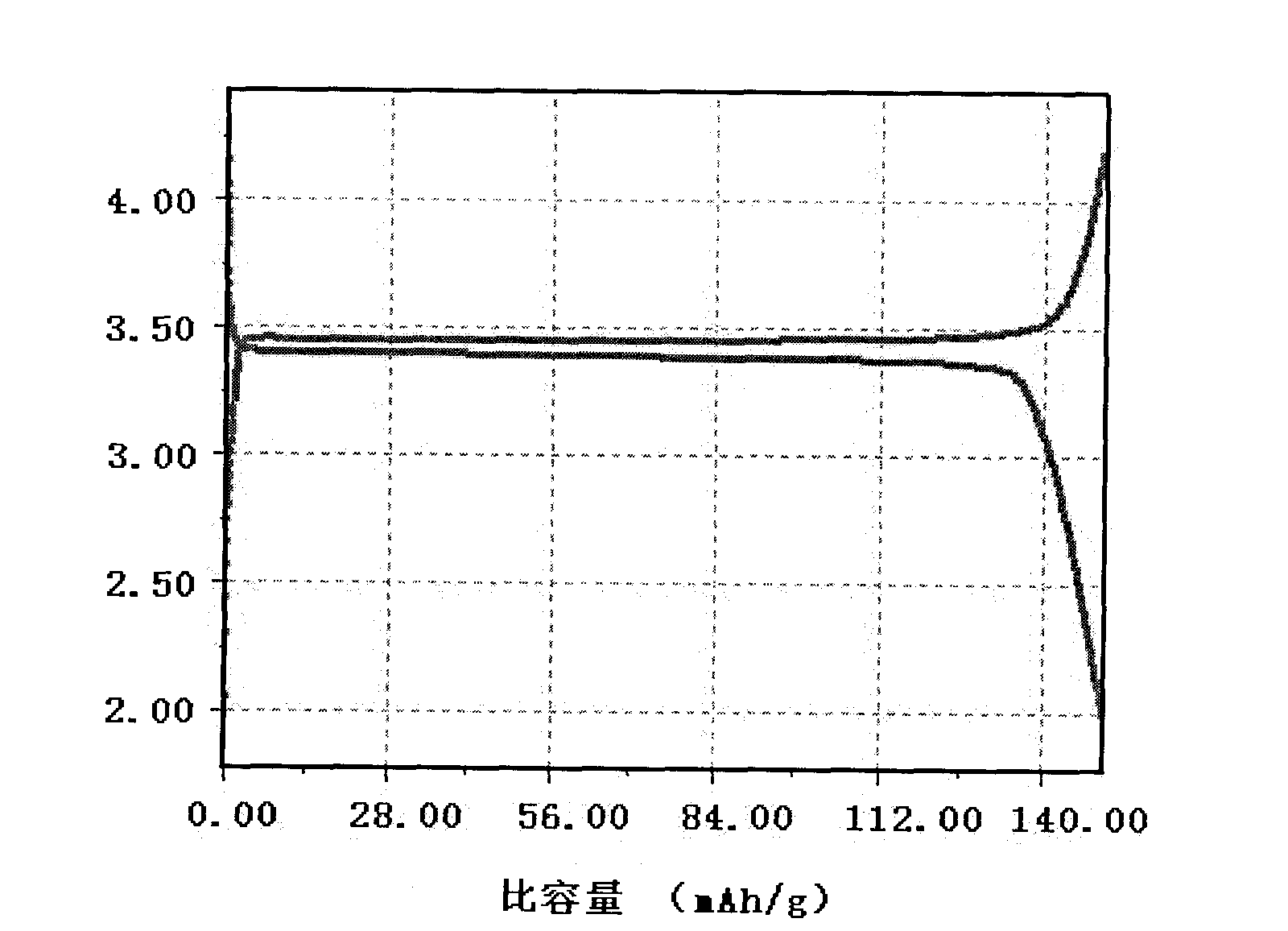

[0023] Embodiment 2 370g lithium carbonate (Li 2 CO 3 ), 1700g ferrous oxalate (FeC 2 o 4 2H 2 O), 1150g ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and 75g antimony trioxide (Sb 2 o 3 ) into an appropriate amount of deionized water, ultra-fine ball milling for 1-3 hours until the particle size is 0.5-1 micron; then use a flash dryer to obtain a spherical precursor at an air inlet temperature of 300°C and an outlet air temperature of 100°C body; the above precursor was pretreated at 200°C for 6h in an inert atmosphere, then heated to 800°C and kept at a constant temperature for 5h, and naturally cooled to room temperature to obtain an antimony-doped lithium iron phosphate material with the nominal molecular formula LiFe 0.95 Sb 0.05 PO 4 , the material is charged and discharged at a rate of 0.1C. When the charge and discharge voltage ranges from 2.0 to 4.2V, the capacity reaches 140mAh / g. After 20 cycles, the capacity remains good without obvious attenuation. LiF...

Embodiment 3

[0024] Example 3 420g lithium hydroxide (LiOH·H 2 O), 960g iron hydroxide (Fe(OH) 3 ), 1320g diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) and 146g antimony trioxide (Sb 2 o 3 ) adding an appropriate amount of deionized water, milling for 1 to 3 hours until the particle size is 1.5 microns; then using a flash dryer to obtain a spherical precursor at an air inlet temperature of 300°C and an outlet air temperature of 100°C; The above precursor was pretreated at 100°C for 12h in an inert atmosphere, then heated to 750°C and kept at a constant temperature for 10h, and cooled naturally to room temperature to obtain an antimony-doped lithium iron phosphate material with the nominal molecular formula LiFe 0.9 Sb 0.1 PO 4 . The material is charged and discharged at a rate of 0.1C. When the charge and discharge voltage ranges from 2.0 to 4.2V, the capacity reaches 136mAh / g. After 20 cycles, the capacity remains good without obvious attenuation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com