Water-in-oil type emulsified gasoline

An emulsified gasoline, water-in-oil type technology, applied in the field of fuel oil for internal combustion engines, can solve the problems of complex preparation work, thermodynamic instability, and a wide variety of emulsifier raw materials, and achieve small and uniform particle size, stable emulsification effect, and excellent anti-corrosion. The effect of external disturbance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

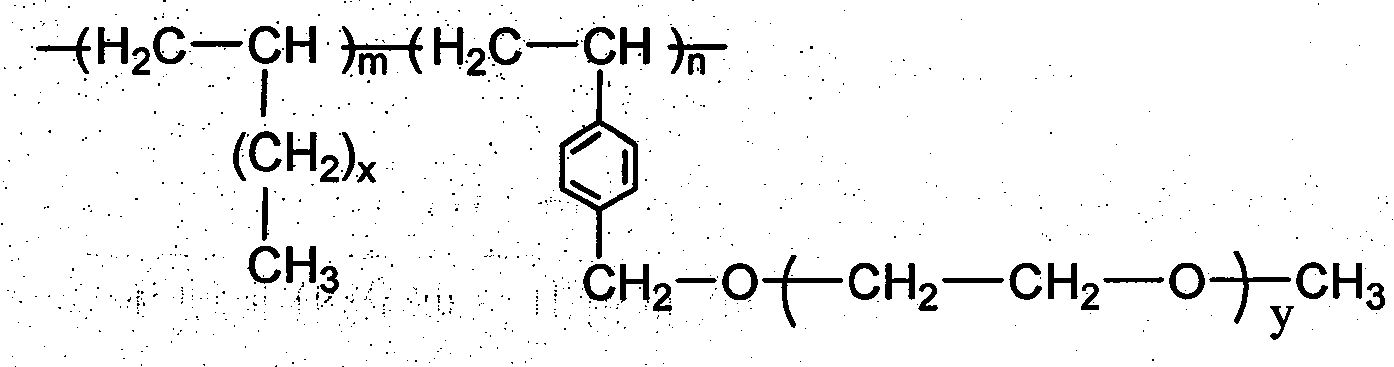

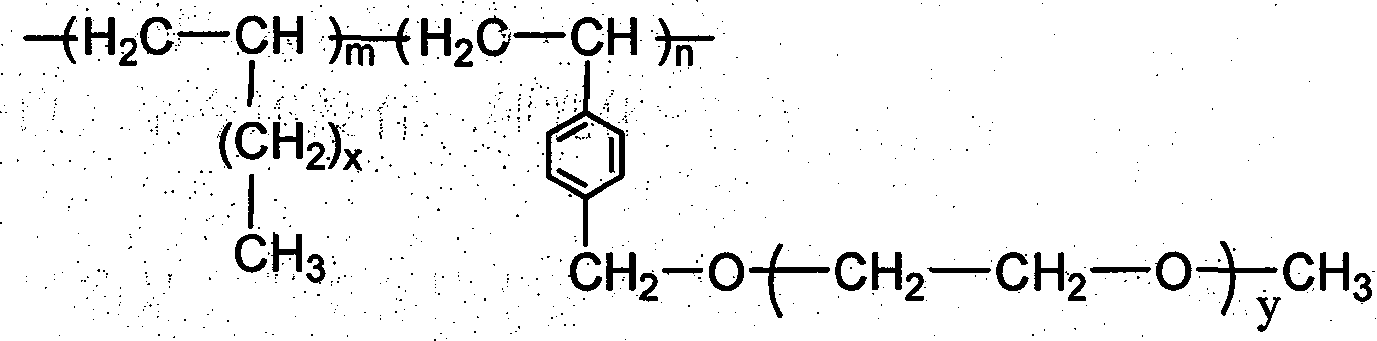

[0022] Blend Span 80 and Tween 80 into a complex emulsifier with an HLB value of 9. Add 8.45 grams of water in 76.05 grams of gasoline, then add 15 grams of composite emulsifier and 0.5 gram of long-chain α-olefin amphiphilic graft copolymer (preparation method is referring to CN 101157759A, α-olefin unit is 1-dodecene, The number average molecular weight is 1.74×10 4 , the content of Polyethylene Glycol is 11.9%), finally with the high-speed shear dispersing emulsifier, stir at 10000 rev / min rotating speeds for 5 minutes to obtain emulsified gasoline. When the emulsified gasoline was stored at 25°C for 63 days, there was no oil-water separation, no gum and sediment. The diameter of water droplets in emulsified gasoline is 263 nanometers. Storage at 40°C for 5 days without oil-water separation. When centrifuged at 15,000 rpm, no oil-water separation will occur within 135 minutes.

Embodiment 2

[0024] Blend Span 80 and OP10 into a complex emulsifier with an HLB value of 9. Add 8.45 grams of water in 76.05 grams of gasoline, then add 15 grams of composite emulsifier and 0.5 gram of long-chain α-olefin amphiphilic graft copolymer (preparation method is referring to CN 101157759A, α-olefin unit is 1-dodecene, number The average molecular weight is 1.74×10 4 , the content of Polyethylene Glycol is 11.9%), finally with the high-speed shear dispersing emulsifier, stir at 10000 rev / min rotating speeds for 5 minutes to obtain emulsified gasoline. When the emulsified gasoline is stored at 25°C for 60 days, no oil-water separation occurs, and there is no gum and sediment. The diameter of water droplets in emulsified gasoline is 1854 nanometers. Storage at 40°C for 5 days without oil-water separation. When centrifuged at 15,000 rpm, no oil-water separation will occur within 130 minutes.

Embodiment 3

[0026] Blend Span 80 and Tween 80 into a complex emulsifier with an HLB value of 9. Add 8.45 grams of water in 76.05 grams of gasoline, then add 15 grams of composite emulsifier and 0.5 gram of long-chain α-olefin amphiphilic graft copolymer (preparation method is referring to CN 101157759A, α-olefin unit is 1-dodecene, number average The molecular weight is 2.1×10 4 , the content of Polyethylene Glycol is 34.0%), finally with high-speed shear dispersion emulsifier at 10000 rev / min speed of rotation, stir for 5 minutes to obtain emulsified gasoline. When the emulsified gasoline is stored at 25°C for 87 days, there is no oil-water separation, no gum and sediment. The diameter of water droplets in emulsified gasoline is 228 nanometers. No oil-water separation occurred when stored at 40°C for 8 days. When centrifuged at 15,000 rpm, no oil-water separation will occur within 200 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com