Preparation method of polyolefine/polyamide alloy material with bicontinuous structure

A technology of alloy materials and polyamides, which is applied in the field of preparation of polyolefin/polyamide alloy materials, and can solve problems such as high cost, unsuitable for industrial production, and strict molecular weight requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention discloses a method for preparing a polyolefin / polyamide alloy material with a bicontinuous structure, including:

[0029] Mix functionalized polybutadiene with a weight ratio of 3-20:80-97 and irradiated or peroxide initiator polyolefin, put it into an extruder, and melt and extrude it at 160°C-210°C. Particles to obtain the first reaction product;

[0030] Mix the first reaction product and polyamide with a weight ratio of 70-85:15-30, put them into an extruder, melt, blend, extrude and granulate at 230°C-300°C to obtain a polyolefin with a double continuous structure / Polyamide alloy material.

[0031] According to the present invention, the functionalized polybutadiene is a compound obtained by grafting reaction between polybutadiene and a functionalized monomer, preferably a product with a high 1,4 structure produced by polymerization through coordination and complexation catalysis, or The product containing 50%-80% 1,2 str...

Embodiment 1

[0039] 1. Put 900g of polyethylene, 100g of maleic anhydride grafted polybutadiene and 1g of dicumyl peroxide into a twin-screw extruder to extrude and granulate after the grafting rate of 100g is 20%. The temperature is controlled at 195° C., and the screw speed is 80 rpm.

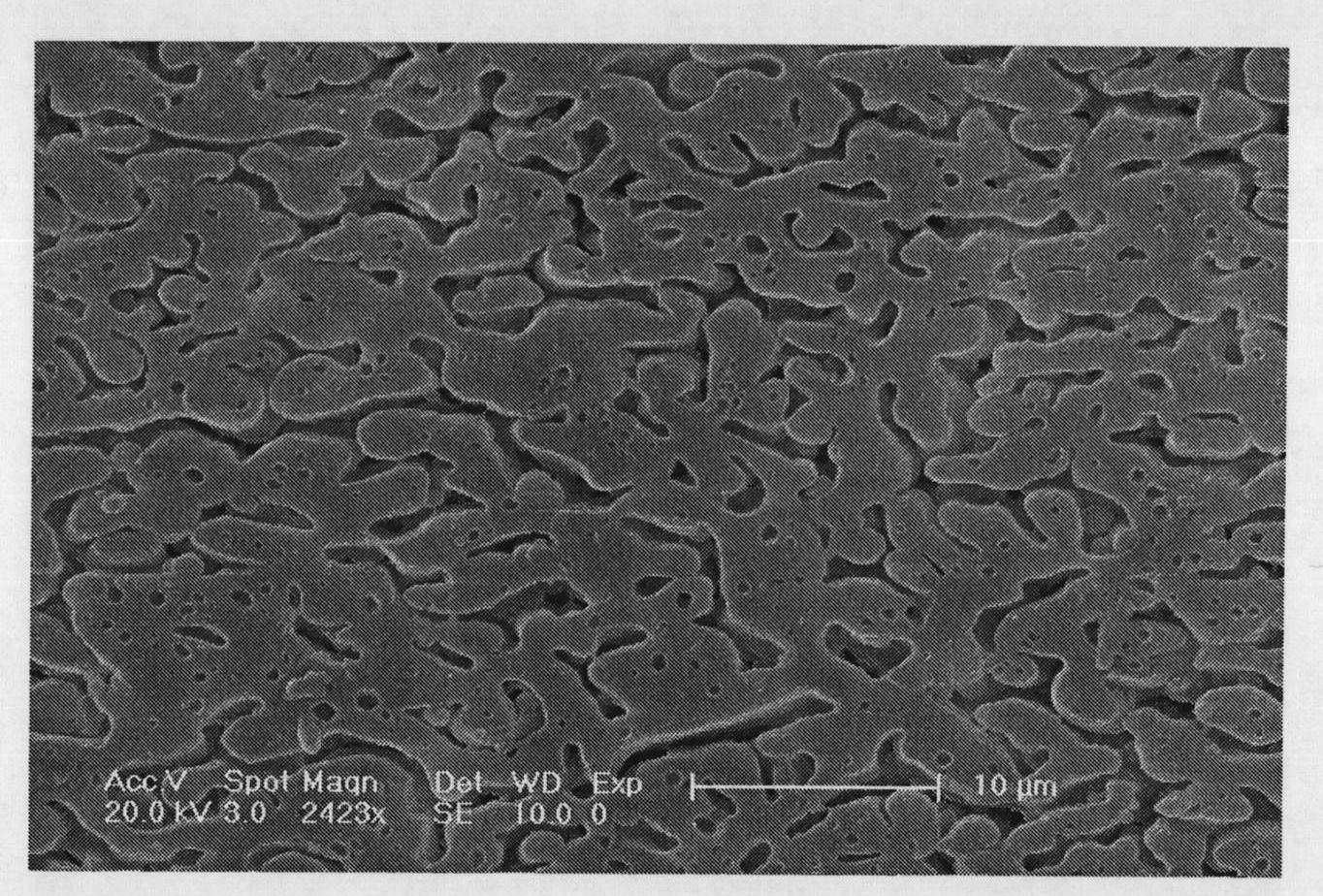

[0040] 2. Mix 750g of the product obtained in step 1 with 250g of polyamide 6 and put it into a twin-screw extruder to extrude and pelletize. The extrusion temperature is controlled at 235°C and the screw speed is 100 rpm to obtain polyolefin / polyamide 6. Amide alloy materials, see figure 1 The scanning electron microscope image of the polyolefin / polyamide alloy material prepared for this example shows that each component in the alloy material forms a continuous phase throughout the entire blend system.

Embodiment 2

[0042] 1. With 450g polyethylene, 550g polypropylene, 50g grafting ratio of 15% maleic anhydride grafted polybutadiene and 0.06g2,5-dimethyl-2,5-di-t-butylperoxyhexane After mixing, put it into a twin-screw extruder to extrude and granulate. The extrusion temperature is controlled at 200° C., and the screw speed is 80 rpm.

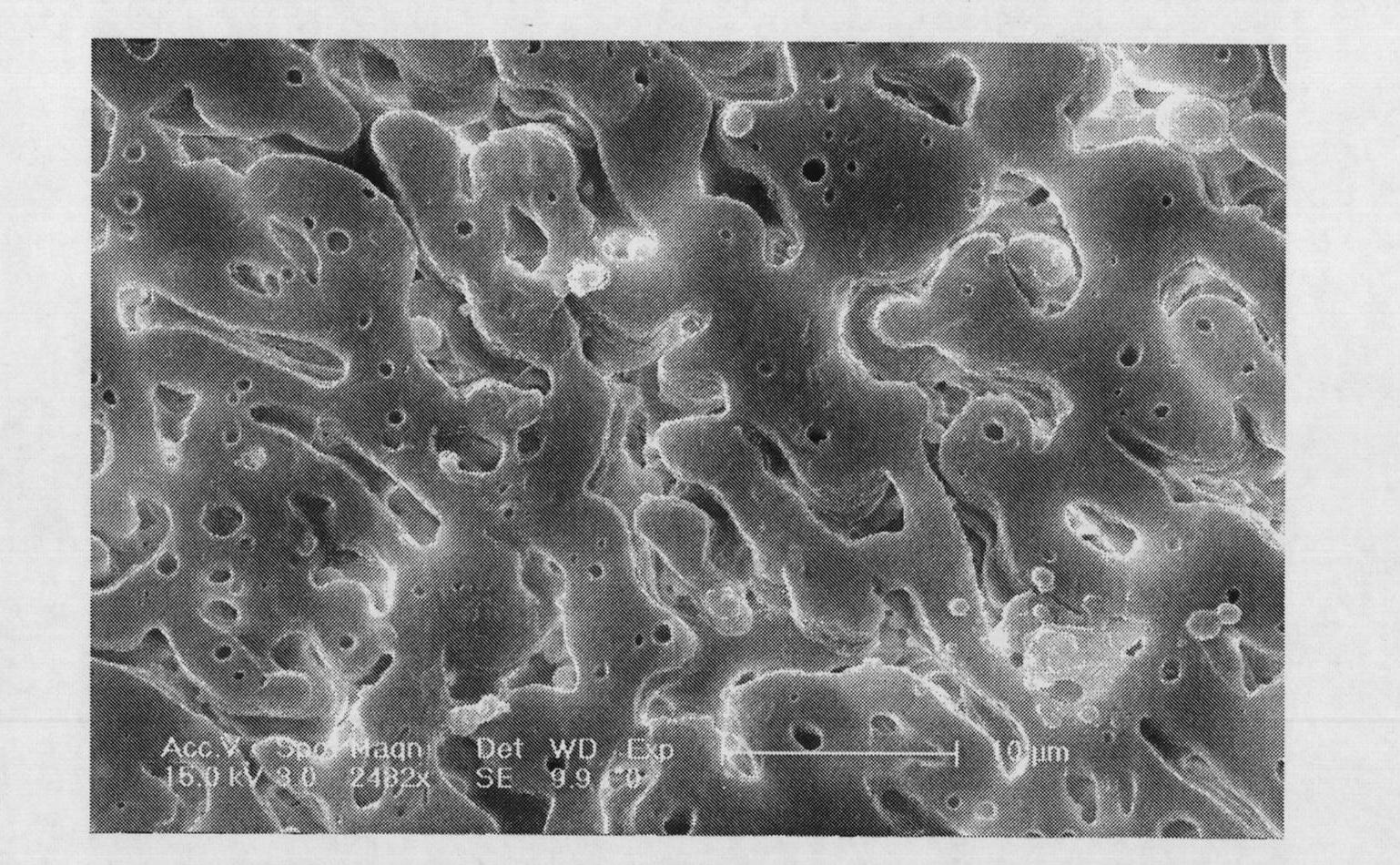

[0043] 2. Mix 800g of the product obtained in step 1 with 200g of polyamide 6 and put it into a twin-screw extruder to extrude and pelletize. The extrusion temperature is controlled at 235°C and the screw speed is 100 rpm to obtain polyolefin / polyamide 6. Amide alloy materials, see figure 2 The scanning electron microscope image of the polyolefin / polyamide alloy material prepared for this example shows that each component in the alloy material forms a continuous phase throughout the entire blend system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com