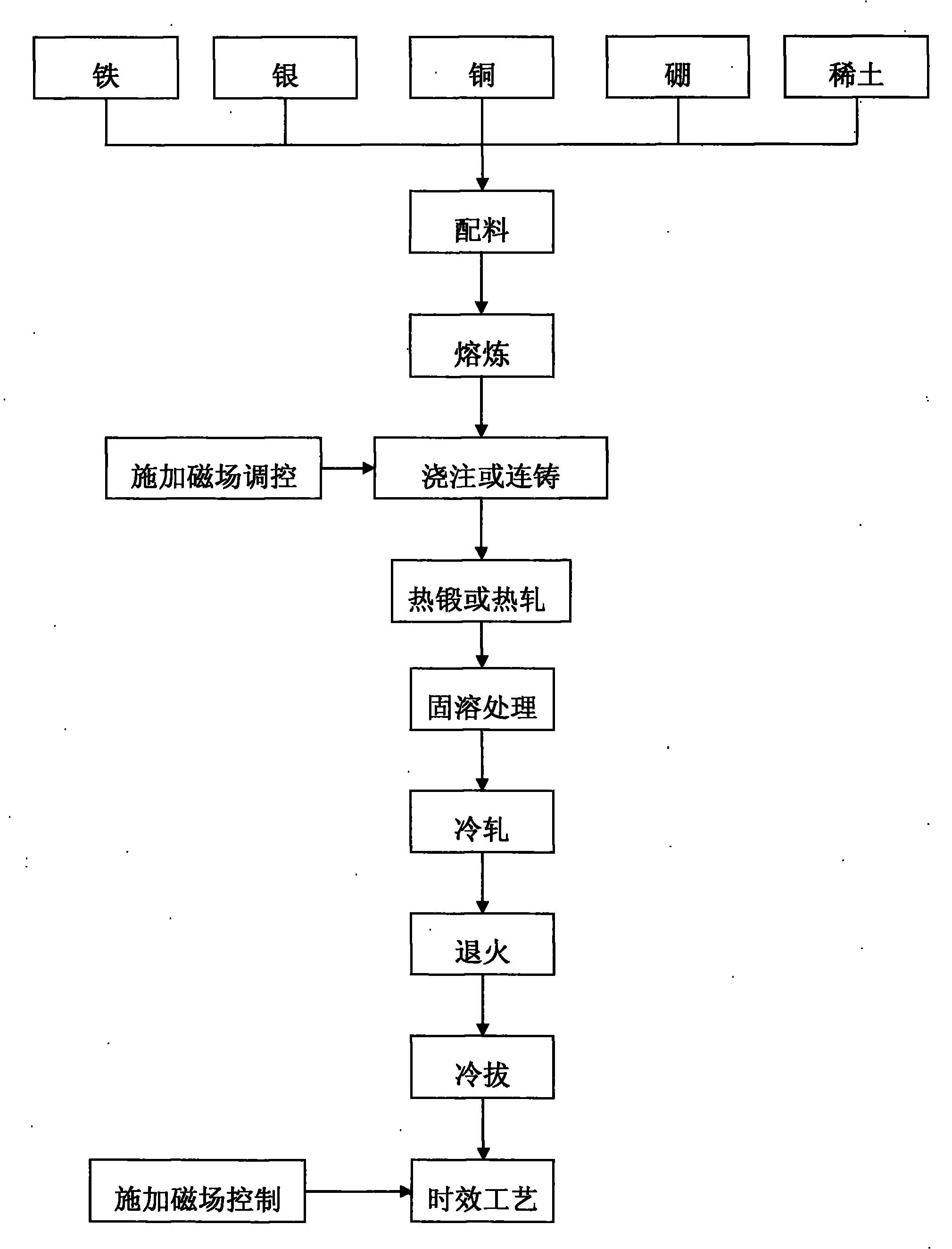

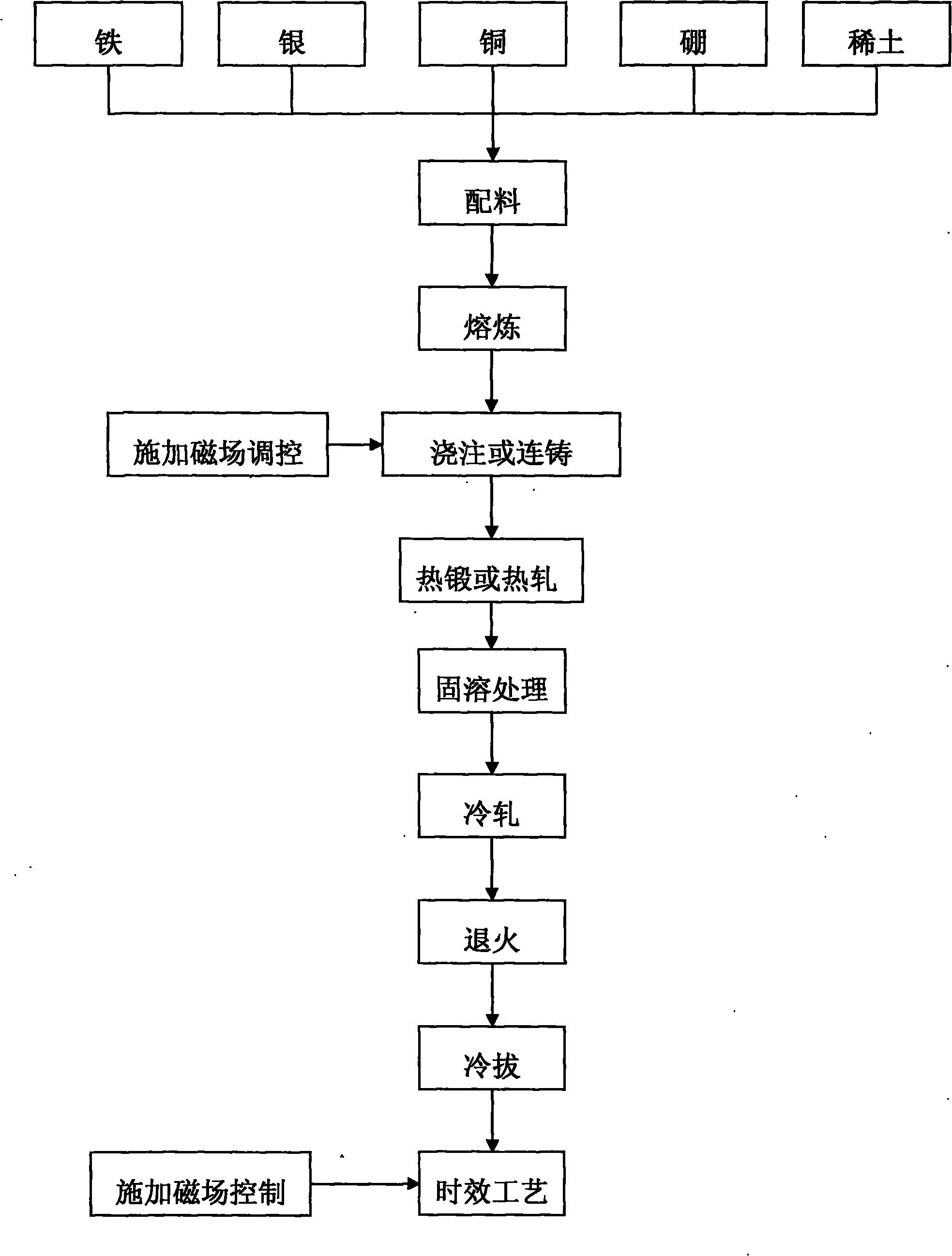

Method for preparing high-performance Cu-Fe deformation in-situ composite material by magnetic field treatment

An in-situ composite material and magnetic field treatment technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as unseen copper alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Ingredients: Material chemical composition (mass percentage): iron: 8, silver 0.05, boron 0.05, cerium 0.01, the rest is copper, raw materials use pure iron, pure silver, boron-copper alloy, metal cerium, electrolytic copper, according to The conventional alloy batching method calculates the addition amount of various raw materials to obtain the batching;

[0037] (2) Smelting: Put the prepared ingredients into an intermediate frequency electromagnetic induction furnace, and melt for 25 minutes according to the conventional copper alloy smelting process;

[0038] (3) pouring: the molten metal is poured into the graphite mold;

[0039] (4) Magnetic field controlled solidification: an AC magnetic field with a magnetic field strength of 0.2T is applied during the solidification process of the ingot;

[0040](5) Hot rolling: put the above-mentioned cast ingot into a heat treatment furnace, heat it to 880° C., keep it warm for 3 hours, and then hot-roll it on a conventi...

Embodiment 2

[0050] (1) Ingredients: material chemical composition (mass percentage): iron: 10, silver 0.08, boron 0.05, yttrium 0.05, the rest is copper, raw materials use pure iron, silver-containing alloy, boron-copper alloy, metal yttrium, electrolytic copper, Calculate the addition amount of various raw materials according to the conventional alloy batching method to obtain the batching;

[0051] (2) Smelting: Put the prepared ingredients into an intermediate frequency electromagnetic induction furnace, and melt for 25 minutes according to the conventional copper alloy smelting process;

[0052] (3) Pouring: pour the molten metal into the water-cooled steel mold;

[0053] (4) Magnetic field controlled solidification: an AC magnetic field with a magnetic field strength of 0.5T is applied during the solidification process of the ingot;

[0054] (5) Hot forging: Put the above-mentioned pouring casting into a heat treatment furnace, heat it to 900°C, keep it warm for 3 hours, and then ho...

Embodiment 3

[0064] (1) Ingredients: material chemical composition (mass percentage): iron: 12, silver 0.1, boron 0.1, lanthanum 0.08, and the rest is copper. Raw materials use iron-containing alloys, silver-containing alloys, boron-copper alloys, metal yttrium, and electrolytic copper. Calculate the addition amount of various raw materials according to the conventional alloy batching method to obtain the batching;

[0065] (2) Smelting: Put the prepared ingredients into an intermediate frequency electromagnetic induction furnace, and melt for 25 minutes according to the conventional copper alloy smelting process;

[0066] (3) pouring: the molten metal is poured into the graphite mold;

[0067] (4) Magnetic field controlled solidification: an AC magnetic field with a magnetic field strength of 0.8T is applied during the solidification process of the ingot;

[0068] (5) Hot forging: Put the above-mentioned cast casting into a heat treatment furnace, heat it to 930°C, keep it warm for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com