High-capacity lithium-ion electrolyte, battery and preparation method of battery

A lithium-ion battery and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of unstable structure of high-Ni materials, reduced cycle performance, safety hazards, etc., and improve the charging and discharging efficiency. , Improve the storage time, inhibit the effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention will be further described in detail below with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

[0027]The battery of the electrolyte of the present invention comprises a positive pole, a negative pole, a diaphragm, an aluminum-plastic composite film packaging bag, positive and negative pole ears, and an electrolyte; wherein the positive pole of the battery is 93% to 96% of the positive active material, 1% to 3% Conductive agent, 2% to 4% binder; the negative electrode of the battery is 94% to 97% of negative electrode active material, 0% to 2% conductive agent, 2% to 4% binder; wherein the positive electrode active material is selected from LiNi x co 1-x o 2 、LiNi x mn y co 1-x-y o 2 One or several amorphous mixtures or / with LiCoO 2 Combination in any ratio, where x≥0.5, where LiNi x co 1-x o 2 x is preferably 0.8 to 0.7, where LiNi x mn y co 1-x-y o 2 In x≥0.5, y≤0.3, th...

Embodiment 1~5

[0034] The preparation method is the same as that of Comparative Example 1, except that the preparation of the positive electrode has the following changes:

[0035]

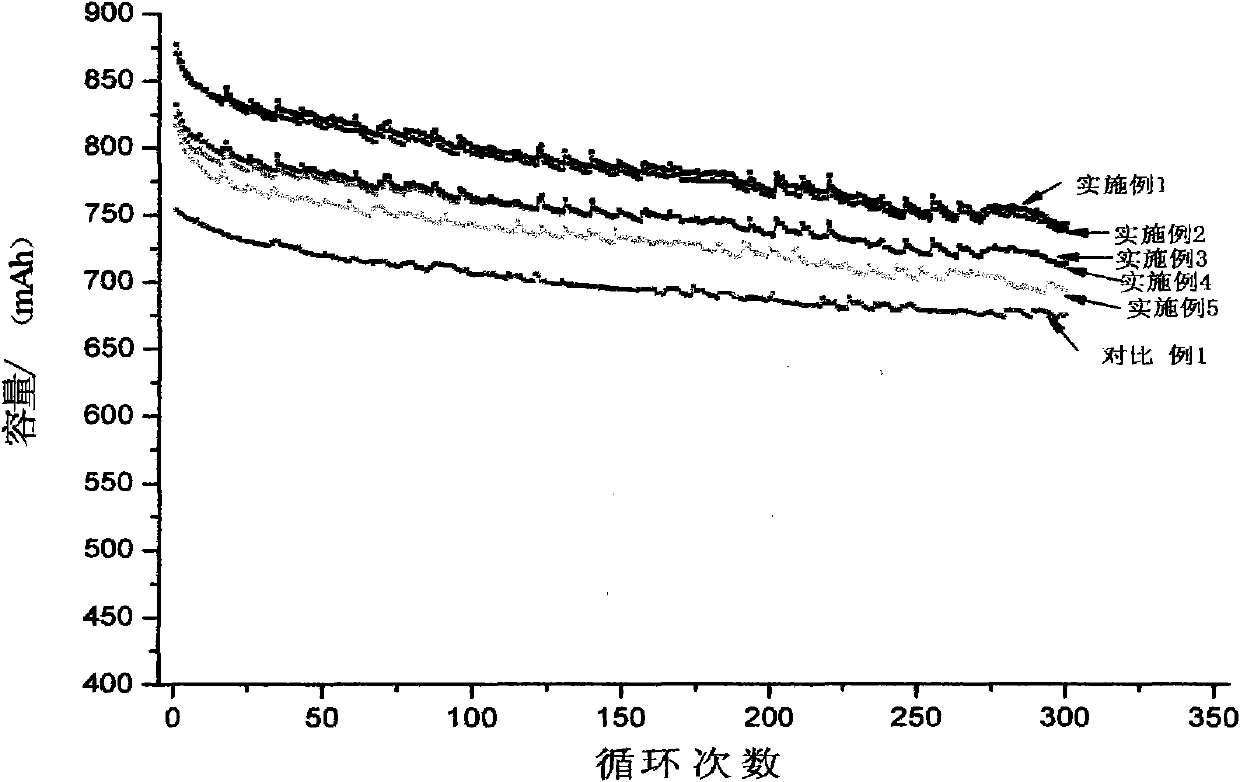

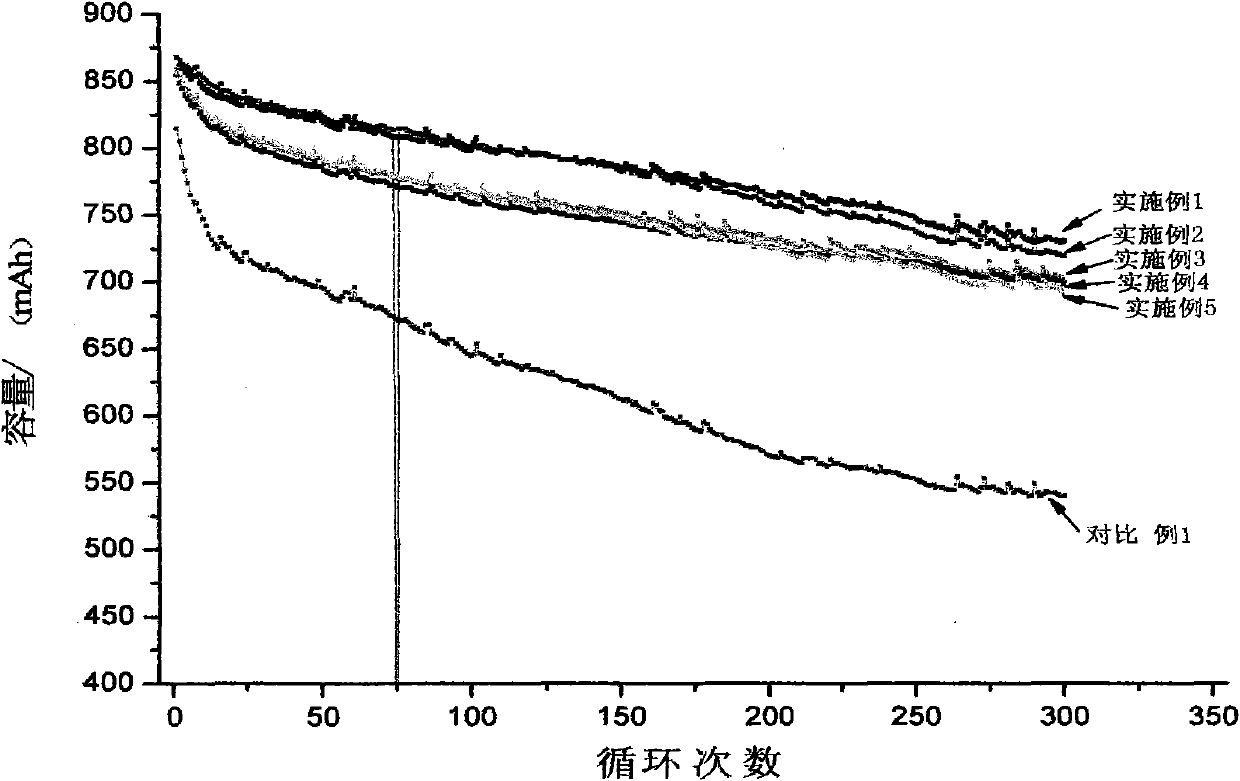

[0036] The prepared battery was also tested for its capacity and cycle performance according to "GB / T18287-2000 General Specification for Lithium-ion Batteries for Cellular Phones".

Embodiment 6

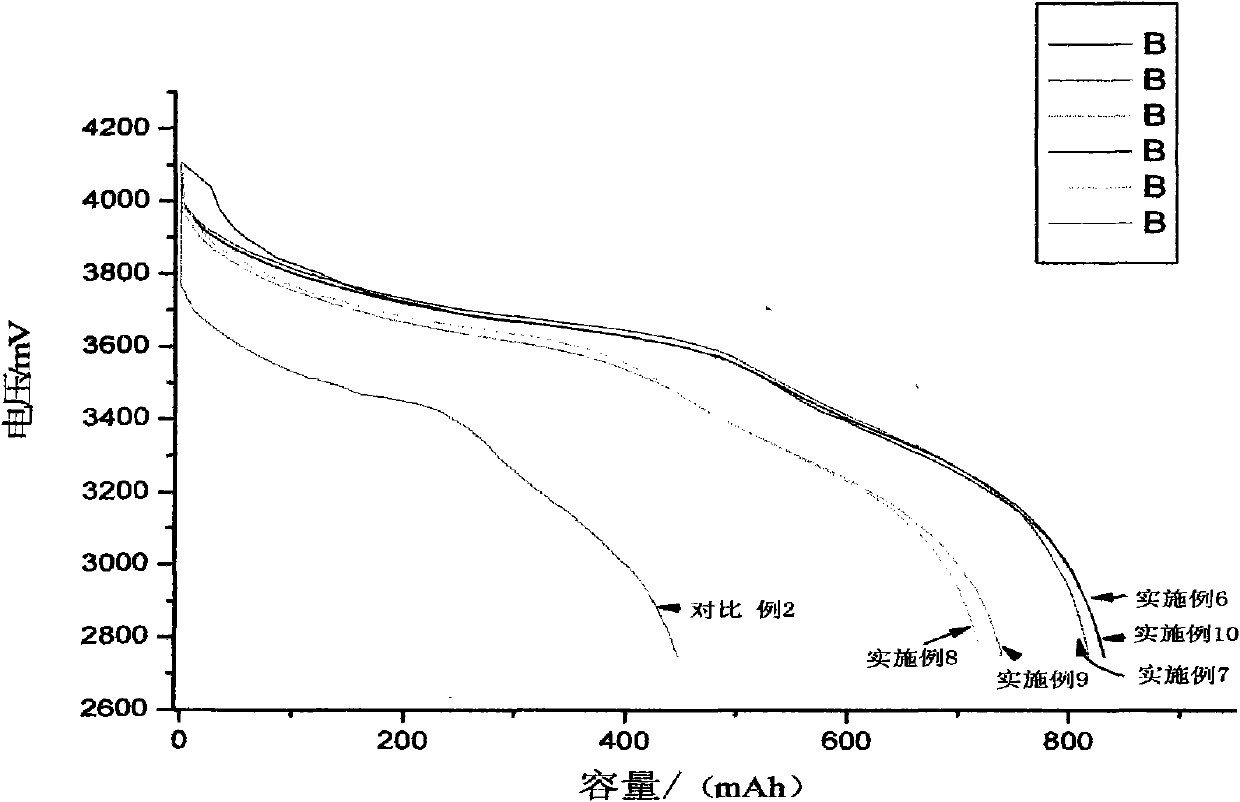

[0040] LiBF4 and LiPF as lithium salts 6 Soluble in ethylene carbonate (EC) / propylene carbonate (PC) / ethyl methyl carbonate (EMC) / diethyl carbonate (DEC) / ethyl butyrate (EB) (mass ratio 20 / 10 / 10 / 40 Obtain solution in the mixed solvent of / 20), wherein the concentration of LiBF4 is 0.2M, LiPF 6 The concentration is 1M. Then in this solution, add vinylene carbonate (VC) by 1% of the total weight of the electrolyte, add ethylene carbonate (VEC) by 0.5% of the total weight of the electrolyte, add 1 by 5% of the total weight of the electrolyte, For 3-propiolactone sulfonate (1,3-PS), ethanolamine is added at 0.1% of the total weight of the electrolyte, and biphenyl is added at 5% of the total weight of the electrolyte to obtain the electrolyte. Add the electrolyte solution into the battery of Example 1 and test its capacity and cycle performance according to "GB / T18287-2000 General Specification for Lithium-ion Batteries for Cellular Phones".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com