Halogen-free flame retarding high-impact polystyrene (HIPS) composite material and preparation method thereof

A technology for flame-retardant high-impact polystyrene and composite materials, which is applied in the field of polymer materials and can solve problems such as low mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

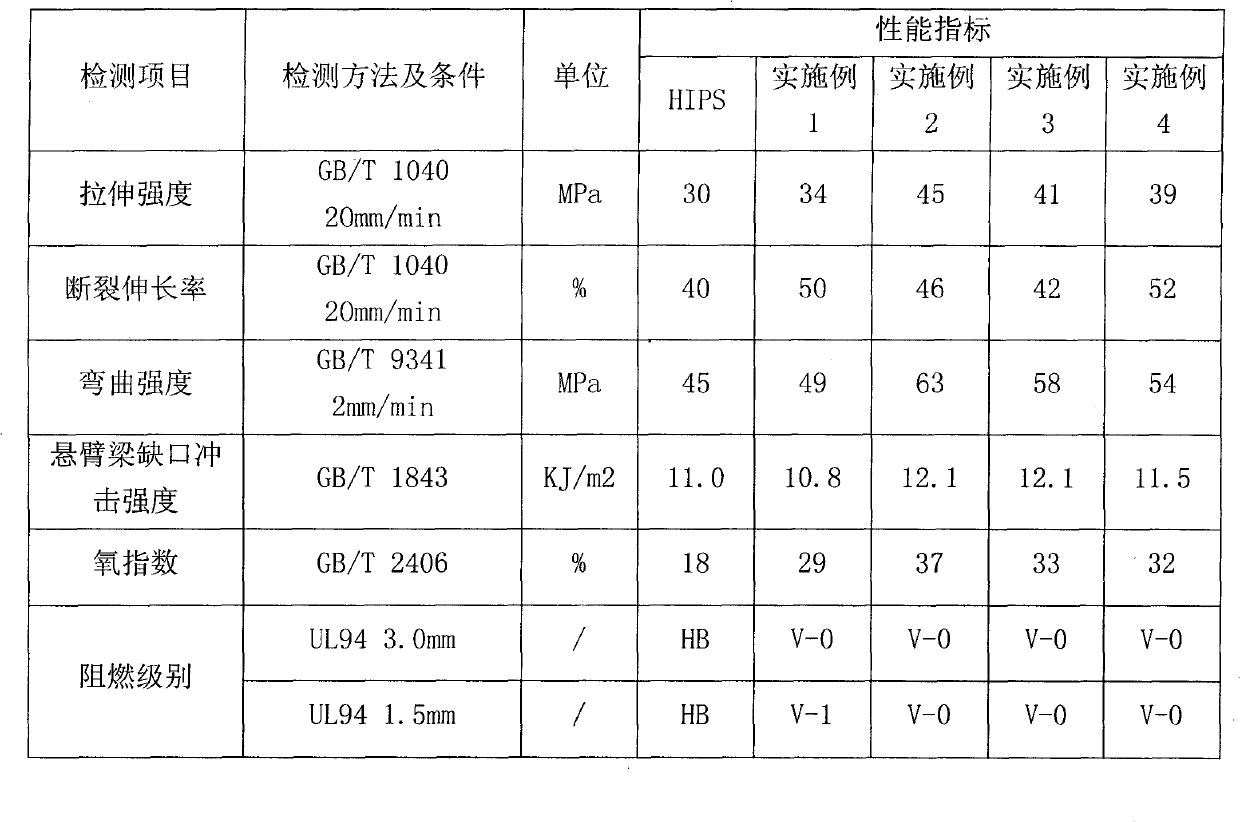

Examples

Embodiment 1

[0019] Formula: 85 parts by weight of high-impact polystyrene, 15 parts by weight of polyphenylene ether as a char-forming agent, 20 parts by weight of flame retardant microcapsule red phosphorus, and toughening agent styrene-ethylene-butylene-styrene block copolymer 15 parts by weight, 1.5 parts of auxiliary flame retardant polytetrafluoroethylene, 1.5 parts of auxiliary flame retardant nanoclay, and 10100.5 parts of antioxidant.

[0020] Preparation:

[0021] 1. Preparation of HIPS / co-flame retardant masterbatch

[0022] The HIPS, auxiliary flame retardant PTFE, and auxiliary flame retardant nanoclay are mixed uniformly under high-speed stirring at a weight ratio of 70 parts, 15 parts, and 15 parts, and then melted, mixed and granulated in a twin-screw extruder. The temperature of each section of the barrel is controlled at 170-190°C, and the twin-screw speed is 100r / min.

[0023] 2. Preparation of halogen-free flame-retardant HIPS composites

[0024] HIPS, char-forming a...

Embodiment 2

[0026] Formula: 65 parts by weight of high-impact polystyrene, 35 parts by weight of polyphenylene ether as a char-forming agent, 5 parts by weight of flame retardant microcapsule red phosphorus, and toughening agent styrene-ethylene-butylene-styrene block copolymer 4 parts by weight, 0.3 part of auxiliary flame retardant polytetrafluoroethylene, 0.3 part of auxiliary flame retardant boehmite, 0.1 part of antioxidant 1010.

[0027] Preparation:

[0028] 1. Preparation of HIPS / co-flame retardant masterbatch

[0029] HIPS, auxiliary flame retardant PTFE, and auxiliary flame retardant nanoclay are mixed uniformly under high-speed stirring at a weight ratio of 90 parts, 5 parts, and 5 parts, and then melted, kneaded and granulated in a twin-screw extruder. The temperature of each section of the barrel is controlled at 170-190°C, and the twin-screw speed is 400r / min.

[0030] 2. Preparation of halogen-free flame-retardant HIPS composites

[0031] HIPS, char-forming agent, flame ...

Embodiment 3

[0033] Formula: 72 parts by weight of high-impact polystyrene, 28 parts by weight of polyphenylene ether as a char-forming agent, 10 parts by weight of flame retardant microcapsule red phosphorus, and toughening agent styrene-ethylene-butylene-styrene block copolymer 8 parts by weight, 0.5 part of auxiliary flame retardant polytetrafluoroethylene, 0.5 part of auxiliary flame retardant nanoclay, 0.2 part of antioxidant 1010, and 0.2 part of antioxidant 168.

[0034] Preparation:

[0035] 1. Preparation of HIPS / co-flame retardant masterbatch

[0036] The HIPS, auxiliary flame retardant PTFE, and auxiliary flame retardant nanoclay are mixed uniformly under high-speed stirring at a weight ratio of 80 parts, 10 parts, and 10 parts, and then melted, mixed and granulated in a twin-screw extruder. The temperature of each section of the barrel is controlled at 170-190°C, and the twin-screw speed is 200r / min.

[0037] 2. Preparation of halogen-free flame-retardant HIPS composites

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com