Flue gas flow equalizing and guiding assembly of selective catalyctic reduction (SCR) denitration reactor inlet

A denitration reactor and inlet technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of not involving variable radius guide plates, variable arc lengths, and no quantitative analysis results. The effect of improving catalyst utilization, reducing kinetic energy loss and improving denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

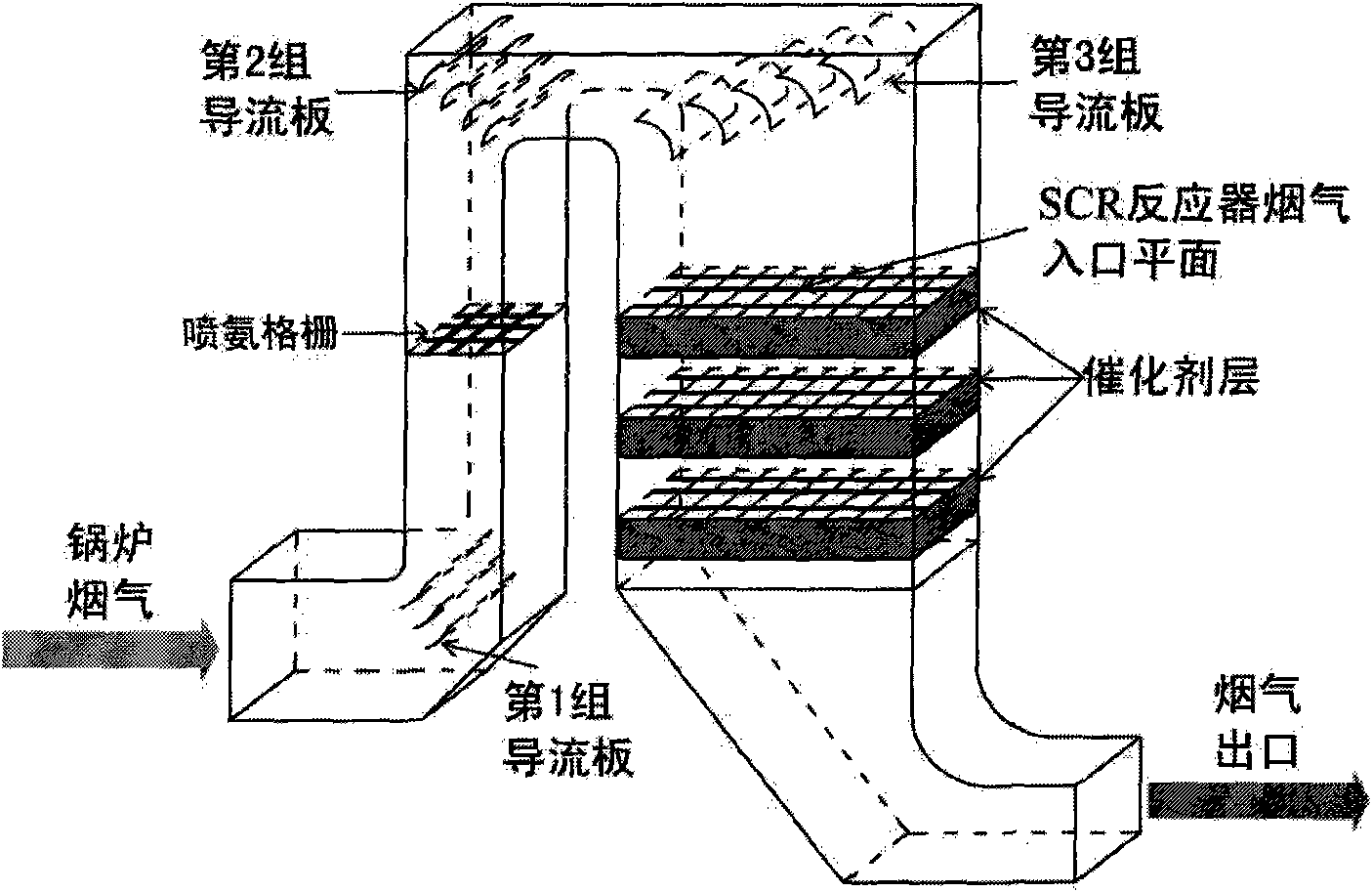

[0017] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

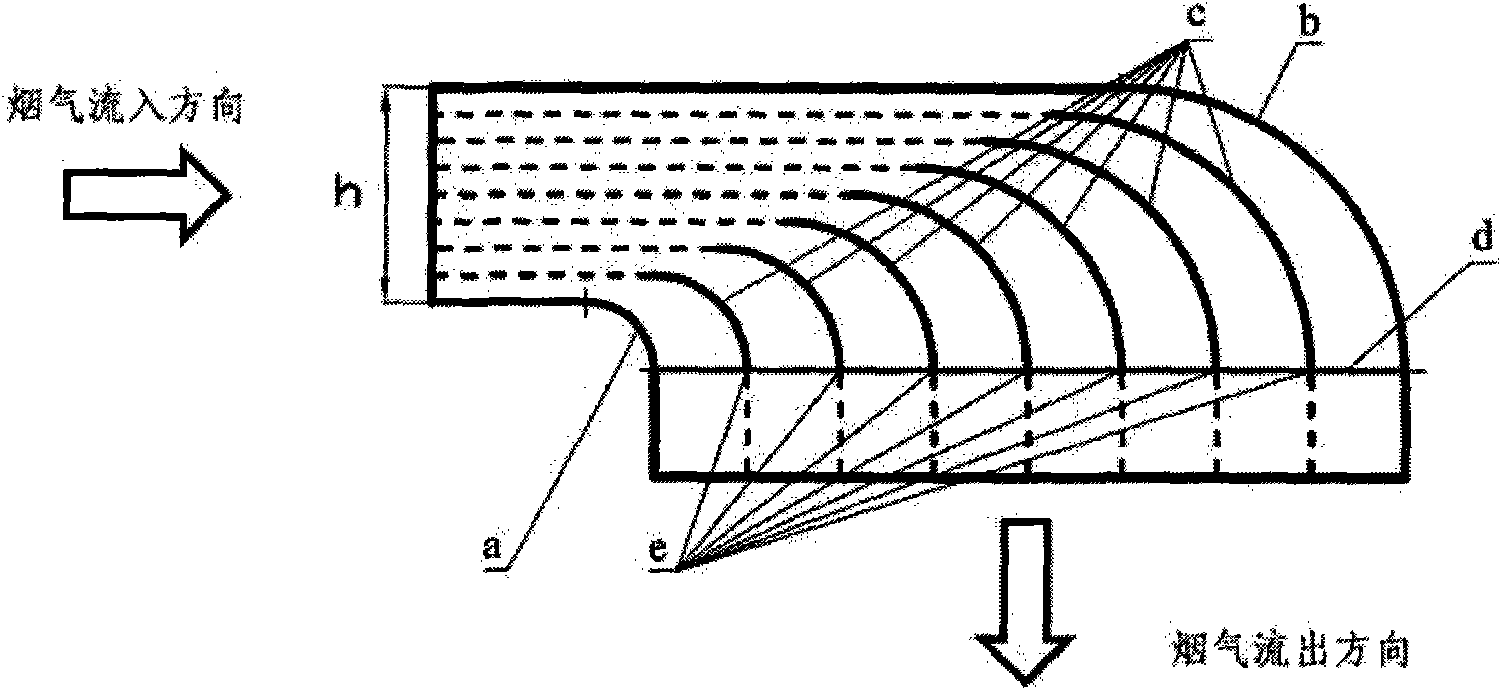

[0018] figure 1 The front view of the bend where the third set of deflectors is shown is figure 2 . In this embodiment, the deflectors with variable radius and variable arc length are used to divide the curved passage into equal parts. The connecting arc of the inner and outer pipe walls of the bend is the inscribed circular arc of the two straight pipe flues (horizontal pipe flue and vertical pipe flue) that need to be connected, and the arc is π / 2. Such as figure 2 In a, b shown. The third set of deflectors in the curve (such as figure 2 The radius and arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com